Tadpole trike front suspension ideas

A "tadpole" recumbent trike has two wheels at the front, a

"delta" trike has two wheels at the back. The tadpole trike I have

on order, currently en-route from China, is the tadpole variety.

Most trikes that I see in Australia have no suspension, occasionally see one with rear suspension. Mine also is the rear-suspension-only type. I recently read that only about 30% of the impact of hitting bumps comes up via the rear wheel, which does make a good case for wanting front suspension. However, as there are two front wheels, if one wheel hits a bump it won't be transferred directly upward, but via the frame arm -- in other words there will be some twisting of the frame that will absorb the bump.

There is a problem when both front wheels hit a bump, as in the situation of corrugated roads in Outback Australia. Yes, there will likely be some absorption via the frame arms. These roads are killers. I posted a photo a few years ago... yes, this post in mid-2019:

https://bkhome.org/news/201907/corrugated-outback-roads.html

I dream of riding my trike across the centre of Australia, on roads like this. The solar panel and delicate electronics will take a bashing. So why didn't I buy a full-suspension trike, then add solar panels myself? -- because the price will more than double.

The difference in price between trike purchased direct from manufacturer in China and from Europe/USA is staggering -- about 2-3 times. Plus, I was quoted a shipping price from one European manufacturer of about 2,000 Euros -- about AU$4,000.

I should mention; there is an Australia company in Melbourne,

Trisled, that manufactures a full-suspension tadpole trike. Yes,

made right here in Australia. But the price is about twice that of

my Chinese trike. Anyway, I have doubts about their suspension

design.

So, if ever do decide to ride across inland Australia, I can convert the front of the trike to have suspension. Ha ha, "fools rush in where angels fear to tread". It does seem doable though. The only tricky bit is might have to do some aluminium welding, for which I will get help.

This is just wild speculation, might never do it. But anyway, have collected photos that show different front-suspension implementations, including some home-built.

Starting with the one that I think is the top-contender, as I can conceive the conversion to be probably the easiest. There was a trike named "Optima Rhino FS", now defunct:

My Chinese manufacturer, Motrike/Trikexplor, did have a full-suspension trike a few years ago, but they discontinued it. They called it their "S320" model:

They still have it listed on their website (yes, I did ask if they would build a one-off just for me, but they politely refused):

https://www.motrike.com/product-item/full-suspension-recumbent-trike/

Here are a couple of home-made designs:

This one is a home-made parallelogram design, that keeps the wheels always vertical to the road:

https://zeept.wordpress.com/2006/05/29/homebuilt-aluminum-trike/

The Arctrike is a failed Kickstarter project:

https://www.kickstarter.com/projects/206205518/the-arctrike-an-all-new-electric-recumbent-trike

Here are some more photos discovered online:

Note, a trike manufacturer, ICE in the UK, has a front-suspension

conversion kit, but only for certain ICE models. Azub in Europe

also has available the components of their front suspension, and I

did consider adapting to my trike; however, was shocked by the

prices.

As stated above, don't know if will ever do this, but very

interesting to think about!

Tags: light

Milo Stove: final assembly and first test

This is post #6. The previous post in this Milo Stove project:

https://bkhome.org/news/202308/milo-stove-making-some-small-parts.html

I decided to use a barbecue skewer on which the pot will sit:

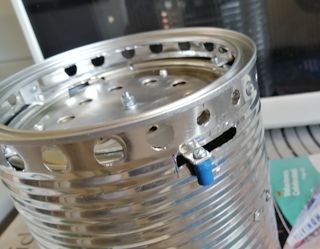

Here is the variable air intake, viewed from underneath:

Assembled in the Milo tin:

...those holes around the base of the Milo tin were drilled with

a step-drill bit. These were recommended by a guy on YouTube, who

explained that ordinary drill bits tend to cut jagged holes in

thin sheet metal, whereas a step-drill bit drills nice holes. Yes,

he is right! I also received an email from Rick advising me how

good step-drill bits are.

Ready to go:

Boiled 500ml water in 4 minutes and 30

seconds, very vigorously boiling at 4 minutes and

45 seconds. That is incredibly fast, which is actually not good.

Well, not what I want anyway.

Reducing the air intake did not reduce the flame as much as expected; it was still fierce. So, could not achieve simmering.

This has been a lesson, and I am understanding the dynamics better. There is too much heat feedback and the alcohol is boiling too fast; reducing air intake does not reduce the alcohol boiling as expected. The Milo tin is too much of an enclosed environment.

I'm getting a clearer picture of how to improve the design. And, getting more of an appreciation of those guys who spend years developing various alcohol stove designs. Which reminds me; forum member ally sent me a couple of links to these guys who tinker with designs for years:

https://www.youtube.com/@MrHiramCook/videos

https://www.youtube.com/@tetkoba/videos

So, back to the drawing board!

Tags: light

Milo Stove: making some small parts

This is post #5 of the Milo Stove project. Post #4 is here:

https://bkhome.org/news/202308/milo-stove-drilling-the-lid.html

I am using the Speedster burner, but intending to make my own. So have purchased five of these little 30ml aluminium cans (from eBay):

The burner will have to sit right on top of a bolt-head, so I indented the underneath like this:

...used some aluminium tube, then hammered it, to get this indent:

The rotating disk underneath the burner, that will throttle the air-flow, will have a little handle outside of the Milo tin, so as to control the throttling. I am using a small screw and part of a spade terminal. The plastic insulation on spade terminals withstands high temperatures. The screw is small enough so as to be able to forcefully screw into the end of the spade terminal (where wire is normally inserted):

The mesh stand that I previously constructed, on which the pot will sit, will probably not be in the final stove. Instead, there will be a grill of some kind, mounted onto the sides of the Milo tin. I used the ring-pull tops of baked-beans tins to create these mounting brackets:

Used a 25mm chassis hole-punch to cut a very neat hole in the chicken-tin:

Did a preliminary burn test, and the flame was not coming out through the hole, so used pliers to widen the hole. The result is not neat, but the flame came out very nicely, perhaps a bit too much:

The Packafeather stove has a 27mm - 27.5mm diameter hole, so

perhaps that is the magic size.

The metal is a bit brittle; could not work it out wider, it tended to break. So might purchase a slightly bigger hole-cutter. Or maybe try a stone grinding wheel to widen the hole a little bit. So, looks like back to Coles tomorrow, to purchase another chicken-spread tin.

As mentioned, will probably not use the wire-mesh pot-stand shown in the above photo. The grid on which the pot sits could be the fan-grill as shown in post #1, or could use stainless steel skewers. Bought these from Coles:

Have other things to do for the next couple of days, but will get

back to this project soon.

Tags: light

Milo Stove: drilling the lid

This is post #4 of the Milo Stove project. Post #3 is here:

https://bkhome.org/news/202308/milo-stove-chicken-tin-and-mesh-stand.html

The lid of the Milo tin is being re-purposed as the base on which will sit the alcohol burner. As mentioned in post #3, the air inlet is underneath the chicken-tin. Here are the holes drilled in the lid:

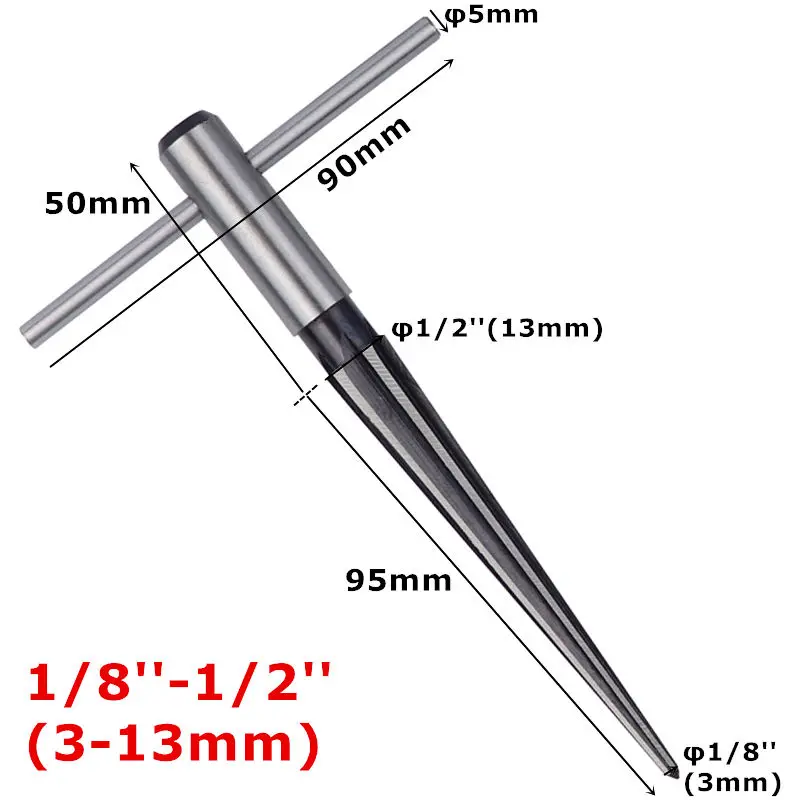

The air-inlet holes are nominally 9mm diameter, though I was a

bit cautious and they are actually more like 8mm.

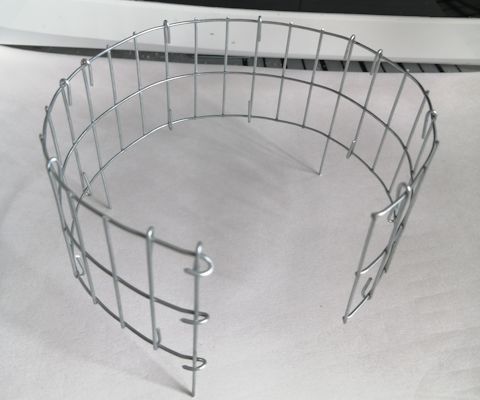

Cutting 8-9mm holes in thin tin is tricky with a hand tool, so I first drilled 2mm, then 5mm, then reamed it out and a final touchup with a round file. My reamer is a hand tool; they are readily available, look like this:

After drilling all the holes, here is what the 30ml Speedster burner looks like when placed on the lid:

The chicken-tin goes over that, held in place by pieces of aluminium rod riveted on three sides:

...have not yet drilled the 25mm hole in the top of the chicken-tin.

The construction plan was created in SolveSpace. Here it is exported to PNG:

As the diagram shows, there will be a circular piece of aluminium underneath the Milo-lid, that can be rotated to adjust air intake.

As you might glean from looking at the diagram, the Milo lid is

about 12mm above the bottom of the tin, with 8mm holes right

around the bottom-side of the Milo tin. Note also, the Milo tin is

being used upside-down.

Of course, this design is an experiment and it will be great if

it performs well, but not guaranteed. If anyone thinks that this

idea for throttling air intake is patentable, I state right now

that the Milo Stove design is public domain. I don't see anything

patentable about it; however, patent law in some countries,

particularly the USA, is so broken that even the most trivial

innovation can be patented.

Tags: light

Milo Stove: chicken tin and mesh stand

I thought maybe call this "Barry's Milo Stove", but just "Milo Stove" is enough; named after the Milo tin.

This is post #3 of the Milo alcohol stove project. Previous post:

https://bkhome.org/news/202308/milo-tin-for-alcohol-stove-project.html

The stove will be built on the same principle as the Packafeather

stove, with burner inside, covered with a tin that has a hole in

the top for the flames to come out. Here is the Packafeather XL

stove:

I looked through the shelves at Coles for a suitable tin to go over the Speedster burner, and found this:

This is Podravka Chicken Spread, made in Croatia. Outer diameter at the widest is 75mm and height is 32mm, which is a bit smaller than I was looking for; however, the next size up was fish tins, that are a bit too big. It's OK, the chicken tin will work.

After removing the ring-pull lid (and cleaning it out), there is a ridge all around the inside, where the ring-pull lid was attached:

The Milo Stove will have air flowing in from underneath, and due to the rather small diameter, needed to get rid of that ridge. A small grinding wheel worked. The electric drill was clamped onto the bench, and it was easy to grind the ridge down:

...still to be done, a 25mm hole in the top of the chicken-tin.

I also constructed a mesh stand, on which the pot will sit. Bought this from Bunnings:

https://www.bunnings.com.au/rapidmesh-600-x-900-x-1-1mm-25-x-12-5-silver-wire-mesh-panel_p0203642

The idea is that when everything is packed into the stove, the

TOAKS pot will be inserted inside the Milo tin, and the mesh stand

can be either inside or outside the pot.

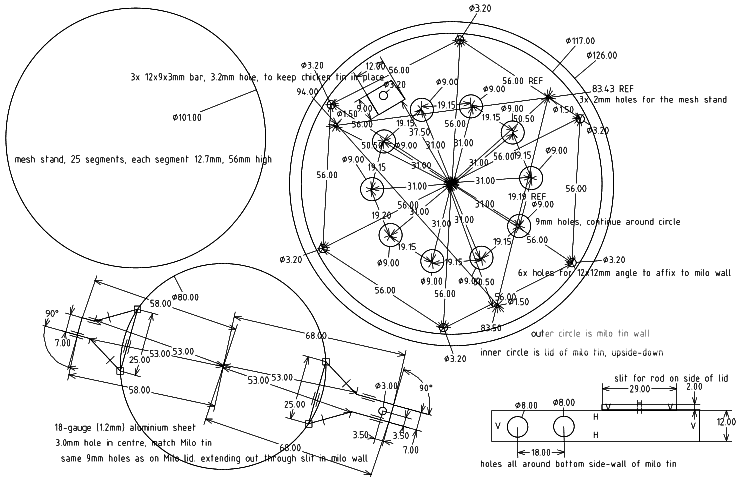

Cut out a piece of mesh, 25 segments, each segment is 12.7mm:

Here it is wrapped into a circle. Circumference is 318mm, diameter 101mm, height 56mm. There are hooks to hold it together:

...the stand looks OK, but not necessarily the final design.

Also, will be considering the alternative method, of a round grill

mounted on the sides of the Milo tin, as shown in post #1 of this

stove project.

Tags: light

Milo tin for alcohol stove project

Continuing the alcohol stove project:

https://bkhome.org/news/202308/experiments-with-an-alcohol-stove.html

Well well, I found a tin exactly the right size, at the local Coles supermarket. It is 700g "Milo Pro":

I used to drink Milo as a child. Have transferred it into a jar, now looks like will have to get into drinking it again. As a hot drink in the evening will be nice.

The Milo tin dimensions are perfect. The tin is slightly higher than the aluminium construction, but that is exactly what I want. Serendipitous!

Have drawn up the plans for the construction, using SolveSpace. This will be a complete DIY alcohol stove with simmer adjustment. Had to order a few bits and pieces off eBay, so will be about a week away before can commence the build.

Those Speedster alcohol burners can easily be constructed, so also have ordered some ceramic wool, fine stainless steel mesh and 30ml aluminium cans. There are YouTube videos that show how to do it:

https://www.youtube.com/watch?v=GZ3mzbskhCE

https://www.youtube.com/watch?v=LK1gifdLPoA

https://www.youtube.com/watch?v=en_iQ_vbRn4

Here is the Speedster 30ml burner:

Up until recently, I went along with the established doctrine that these simple burners are the least efficient, despite my own tests showing otherwise. Then I saw this video, that finally has thrown out the false information about efficiency:

https://www.youtube.com/watch?v=-GFCofvFVM0

...testing an X-Boil burner, which is same principle as the

Speedster. The simplest burner is great!

Tags: light

Experiments with an alcohol stove

Several days ago, I posted some thoughts about alcohol stove design:

https://bkhome.org/news/202308/some-thoughts-about-alcohol-stove-design.html

So, considered testing with the combined Speedster burner and Packafeather adjustable stove. Also, I wondered how close the windshield could be to the pot and still draw the fumes upward ok.

So, I constructed an aluminium windshield tube, with brackets inside to hold a grill, on which the pot will sit. The gap between pot and innner-side of windhield is only 5mm (using my TOAKS 1000ml titanium pot). The aluminium sheet is 0.5mm thick. Photo shows the constructed windshield/pot-stand, alongside the Packafeather stove:

That grill is actually a fan grill. They have welded joins and will withstand considerable heat -- in fact, while testing it was glowing red hot and held together. I bought it from here, the "120mm" size, which is actually 115 wide by 115mm high:

https://www.aliexpress.com/item/1005005572335210.html

With 500ml in the pot and the Packafeather vents wide open, it burned very hot. Here is a snapshot with the lights out:

From the post several days ago, I had the idea of combining the

Packafeather with the Speedster, so set that up. Started with

500ml water -- a US cup is 238ml, so a bit more water than many

tests on YouTube where they use two US cups for a boil test. No

lid on the pot.

Winter here, cool evening. Didn't measure the temperature, but estimate ambient and water to be about 15 degrees C. With the Packafeather vent wide open, boiling was starting to happen after 10 minutes, became vigorous at 12 minutes.

At that point, I wound the Packafeather vents down to fully closed, and the flame became small. This is what we want for true cooking, to leave on simmer, so that the beans, seeds, legumes, or whatever, have fully cooked. Then waited until the flame went out...

The Speedster burner is "30ml" and at the start I put as much in until it was full. Didn't measure, but it would have been about 30ml. After a short time, turned the vent to be very slightly opened, then waited...

The flame went out after 48 minutes and 45 seconds!

Wow, that is a long simmer. That was yesterday. Today investigated the other idea from the post several days ago, of placing an aluminium doughnut-ring over the Packafeather stove. Also, instead of the grill, decided to use the Packafeather mesh stand:

Still using the Speedster burner, again filled to the brim. This

time, it caught me by surprise. I looked at the pot after 8

minutes and 48 seconds, and hey, it was already boiling -- very

vigorously. I don't know when it started boiling.

I immediately turned the Packafeather vent to closed. A couple of minutes later, the flame went out and I checked, all of the fuel was gone.

The lesson here is that the Speedster was getting too hot, boiling the alcohol too fast. Yes, got a very fast boil, but not so good for simmering.

Interesting, it is a balancing act. We don't want the burner, that is, whatever is holding the alcohol, to get too hot. Nor to cold -- which is why those who go camping in alpine areas carry some foil to put under the burner, as insulation from the ground.

This is all "fuel" for further thought. It would be nice to publish a DIY design that has adjustment like the Packafeather -- but doesn't require an actual Packafeather, given that they are no longer available.

And, I wonder if there is a tin can about that size. The

aluminium tube that I constructed is 130mm outside diameter, 125mm

high. Will go hunting the shelves at the local

supermarkets.

Tags: light

Some thoughts about alcohol stove design

I posted recently about planning a new windshield and stand for my titanium pot:

https://bkhome.org/news/202307/idea-for-a-stove-windshield-and-stand.html

There are two little stoves that I own and love. The Speedster stove:

https://bkhome.org/news/202109/helena-campsite-and-speedster-stove-test.html

And the Packafeather XL stove:

https://bkhome.org/news/201606/packafeather-xl-stove.html

...you can see, it is just a cup into which alcohol is poured, and an outer part goes over it to control the airflow. The great thing about this is it can be adjusted down to simmer, which allows to cook food, not just bring it to the boil.

Zen Stoves is a wonderful site for those interested in the design of alcohol stoves. This page explains that the simplest type, like the Speedster stove, is slightly less efficient that one with an outer air control like the Packafeather . That's the "Open Flame Alcohol Stoves" and "Chimney Alcohol Stoves":

https://zenstoves.net/Stoves.htm

The greatest advantage of the Speedster stove is that it is spill-proof. The fuel can be left in it and the lid screwed on. Even with fuel in it and the lid off, it can be turned upside-down and no fuel comes out.

Why can't the two, Speedster and Packafeather, be used together? Replace the cup into which alcohol is poured, with the Speedster. Yes, I tested it and it works great. The flame is controllable right down to a simmer.

So, have decided to go for that combination. Then, watching some YouTube videos, came upon what this guy did with his Packafeather stove:

https://www.youtube.com/watch?v=NsTD-V6R3QY

He created an aluminium foil ring, that fits on top of the stove, then the windshield is placed around it:

Note, his Packafeather stove is a different model than mine,

different brackets on which to place the pot. The little brown

part is the handle for a cap used to extinguish the flame. The

foil ring placed on the stove:

...that is very interesting. He is restricting the airflow that comes in through the windshield holes, so that most will go via the holes in the Packafeather. I'm going to try that!

Unfortunately, Packafeather stoves are no longer manufactured. It

was a one-person cottage industry. It's a shame when innovative

little products like that just disappear. It's the same with

websites; my blog for example has years of informative posts, but

after I die or go gaga, the domain name will expire and that's the

end of it. Anyway, that's the way it is, time marches

on.

Tags: light