Constructing water distiller inlet

Continuing the construction of solar water distiller prototype #3, here is the previous post:

http://bkhome.org/news/201909/cutting-inner-slots-and-runoff-holes.html

In the prototypes #1 and #2, the water inlet was an aluminium tube

running horizontally across the top, with two or more tiny holes in it,

through which the water trickled. I had difficulty with getting an exact

flow rate, and experimented with an external flow reducer, see here:

http://bkhome.org/news//201906/testing-pope-4-litre-per-hour-dripper.html

I am using this external flow-control system for prototype #3. Inside

the water distiller, there will just be one hole that the water comes

out from, and it is intended to spread out so that it flows down the

entire width of the wicking cloth.

There have been several iterations of the inlet pipe, and even got to

the point of buying some parts then changing my mind, hence wasting

money.

Until recently, it was going to be a 12mm OD aluminium round pipe,

with 12mm holes drilled in the wood frame on both sides to hold it.

However, the inner sheet of glass, on which the wicking cloth lies, will

also have a silicone mat between glass and cloth -- that mat will have

folded-up lips on the sides, to form a sloping tray, to keep the water

contained.

The 12mm pipe resting on top of the wicking cloth will compromise the

lips of the silicone mat at the sides. hence had to rethink the design.

What I decided on is to use 12x12x1.5mm aluminium channel, length

slightly less than the inner width of the distiller, with brass rods

extending into the wood frame to hold it in place. This creates a gap on

the sides for the silicone mat lip.

First step, buy the channel, AU$5.81:

https://www.bunnings.com.au/metal-mate-12-x-12-x-1-5mm-1m-aluminium-channel_p1079307

I decided to use standard 4mm trickle fittings for the inlet piping. I

already have 13mm trickle/drip fittings, a inline filter and the

flow-control construction described in the above link. Hence, need to

reduce to 4mm and bought this, a 13mm to 4mm adaptor, AU$3.64:

https://www.bunnings.com.au/ladco-13mm-end-flow-irrigation-poly_p3110770

I could have used cheap 4mm trickle irrigation pipe, however decided

to go for silicone tube. Main reasons, it is translucent so can see the

water inside, secondly it is highly UV-resistant. I went for silicone

tube 3mm ID and 6mm OD, so the wall thickness is 1.5mm. Earlier this

year I had purchased silicone tube from China, via eBay, to suit the

13mm trickle fittings, with a 1mm wall thickness, but I found that it

kinks very easily. Smaller diameter tube is less likely to kink, but

decided to play safe and go for the thicker wall.

I thought to also use this 3mm ID tube for the outlet of the

distilled water, however, was concerned that the surface tension of

water might impede the flow through such a small diameter tube. So for

outlet, chose 4mm ID and 7mm OD, 1.5mm wall thickness.

The silicone tube can be purchased from China cheaply, for example:

However, I wanted it NOW, so purchased from a local supplier, here in Perth, Western Australia. A very premium price. The company also has an eBay store and they send by Toll Express:

When the DIY plans get published, it will be recommended to save some

money and buy from China, if there is no cheap local supplier. The

price will be AU$4.44 for 3mm ID 6mm OD, and AU$4.76 for the 4mm ID 7mm

OD, 1 metre lengths.

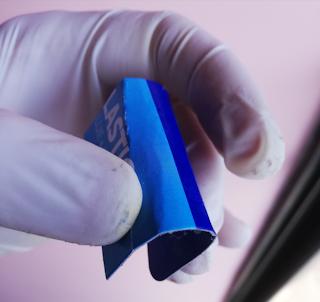

The channel is cut to length 554mm, so as to fit inside the wood

frame with slight gaps both sides of a couple of millimetres. A 4.5mm

hole is cut in the middle, and a slot cut on the right side 6mm wide and

9mm deep. Like this:

...you might not be able to make it out in the photo, but I gouged

lines on the top and bottom insides, as the channel is to be filled with

silicone sealant, and the gouges will help it to grip to the channel.

I purchased 4mm 90 degree elbow spur-fittings, supplied in a 10-pack, AU$4.20:

https://www.bunnings.com.au/pope-4mm-barbed-elbow-10-pack_p3121007

I cut the spur off one end of an elbow and attached the 3mm ID silicone tube to the other end. I pushed it into the hole, like this:

On the right side, the silicone tube is pushed slightly into the

slot. The reason for this is there will also be a brass rod sticking out

from the end, and there needs to be a slight separation between the two

holes that will be cut in the wood frame. Snapshot:

...I cut off two short pieces of silicone tube and placed them on the

left side -- when the brass rod gets positioned, it will be resting on

top of the silicone tube, same situation at left and right sides.

I used some silicone sealant to fix the tube in place, and left

overnight to set. The above photo shows the sealant applied, and the

photo was taken the next day. I am using Selleys 401 acetic cure

silicone, because it is rated food-safe and has superior bonding to

silicone and glass, this one at AU$19.65:

https://www.bunnings.com.au/selleys-310g-401-rtv-engineering-grade-silicone_p1231042

Brass rod is available via eBay, however also sold at many local

hobby shops. I purchased K&S brand (made in USA) 1 foot length 5/32

inch diameter (305mm, 3.97mm) brass rod from PerthRC hobby shop, Lord

Street, Perth, for AU$4.49:

http://www.perthrc.com.au/brass-rod-solid-5-32x12-1-pieces-per-card.html

Cut it in half, gouged with a file edge, and placed into the channel,

sticking out about 10mm each end from the channel, embedded in silicone

sealant. Used various tools and implements to hold the rods in place

and left overnight. Here is a view of the left side:

...you can see that the rod is at the same height as the channel. To

help fix it in place more securely, I wanted the sealant to have a

convex surface, so as to completely encircle the rods. So, the following

day, used a small piece of cardboard as a spreader for the final

application of sealant:

The sealant was applied along the entire length of the channel, then

dragged the piece of cardboard along the entire length to form a nice

slightly-convex surface.

Finally, here are views at the right side:

|

|

There is one important detail. Notice the outlet hole, where the 4mm

plastic elbow is pressed through the channel. It is on the up-slope

side, not facing down-slope. So, there will be a slope, about 30

degrees, and the hole seems to be on the wrong side. This is part of the

plan. The water will trickle out and run along the up-slope side of the

channel and work its way underneath through the wicking cloth. This

mechanism is intended to help the water to spread out the width of the

distiller. This is so far entirely theoretical!

The next step will be to drill holes into the wood frame so as to mount this assembly.

Tags: nomad