Considering ball joints for wheel knuckles

I posted about three different types of ball joints that I purchased for comparison:

https://bkhome.org/news/202403/heim-versus-ball-joint.html

Today I was at the workshop where retired guys get together and work on little projects. Lots of good equipment there. Thinking about what ball joints to use with the wheel knuckles.

Back in early January I was working on the wheel knuckles, intending to fit them to the cheap swing-arms that I purchased from China:

https://bkhome.org/news/202401/construction-of-wheel-knuckle-hinges-and-learning-to-weld.html

Various problems with those swing-arms. Sloppy pivots is the main problem, but also the design became very big and heavy; not really what I want for a trike. While my thumb has been healing, have rethinked the design; hence purchase of the ball joints for consideration.

The workshop has some old 40x40mm steel square tube, and I cut out some cubes. Actually that square tube is fencing post, available from Bunnings, but I found an old length to cut up. Here is the first consideration:

...the cubes are just balanced in place, to see how it will look. I won't rush into doing it this way, as it will be a one-way process; the cubes will have to be welded onto the wheel knuckle.

Any downsides? The main one will be limited vertical displacement, restricting how big a bump can be handled.

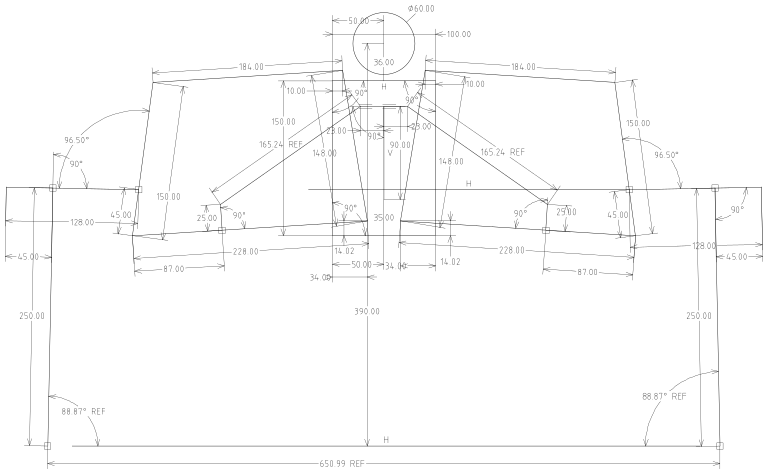

The spacing between the ball joints is ok. I looked at it with SolveSpace:

...notice that 390mm distance; that is the height of the trike frame above ground. That is intended to be the rest position, with someone sitting in the trike. The distance between the wheels on the ground is 650.99mm.

If the trike frame is pushed down, which would be the same as riding along and both wheels hitting a bump, this table shows how the wheel spacing (on the ground) varies:

| Height |

Spacing |

| 390 |

650.99 |

| 380 |

651.93 |

| 370 |

652.28 |

| 360 |

652.05 |

| 350 |

651.23 |

| 340 |

649.85 |

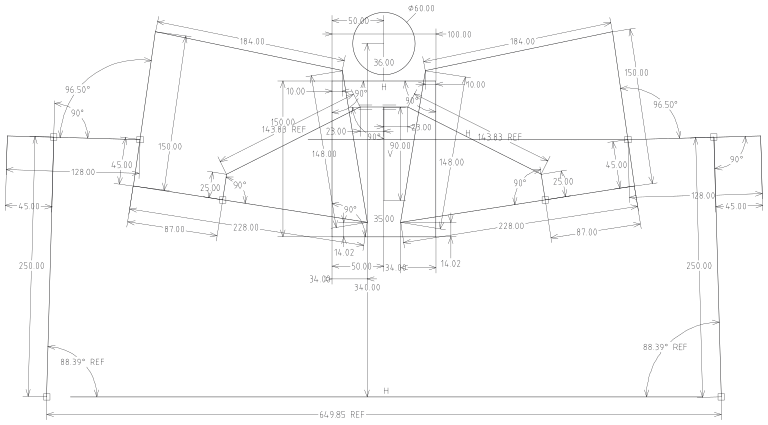

...wheel scrubbing is at most 1.3mm (0.65mm per tyre); negligible. Snapshot from SolveSpace, at height of 340mm:

...looks good. The ball joints could handle a bit more vertical displacement; just looking at it in SolveSpace, it seems the height could go down to about 320mm, at which point the shock absorbers would also be reaching their limit -- 70mm vertical displacement, a little bit under 3 inches. That's a pretty big bump.

Next-up will consider the wheel knuckle with heim

joints.

Tags: light