Testing bonding of Selleys 401 silicone sealant

I am gradually building up expertise with using suitable materials and construction techniques for the solar water distiller.

Prototype #1 is just about ready to have the glass put on top. It has

been a winding road getting to this point. The objective is that I will

publish a set of plans, for anyone to DIY. The final design needs to be

very simple, and prototype #2 might be it.

With the first prototype, I made an assumption that turned out to be

false. I had read in various places online, that silicone sealant will

stick better to wood if it is first primed -- well maybe, but the

product I chose had the opposite effect.

Prototype #1 is built with premium plywood base and pine sides, and I

coated it with Dulux Duramax primer/undercoat (spray can). Purchased

from Bunnings:

https://www.bunnings.com.au/dulux-duramax-340g-undercoat-spray-paint_p1400722

Adhesion of the Selleys 401 silicone sealant is very poor, I can

scrape it off with my fingernail. Surprisingly, adhesion to aluminium

sheet is also poor, and again I could scrape it off with my fingernail.

This sealant is acidic-curing, and I expected it to bond well to

aluminium. Need to do some testing on different surfaces!

Spreading of silicone sealant

prototype #1 has an aluminium sheet on top of the plywood, and the

black wicking cloth goes on top of the aluminium sheet. I did consider

coating the plywood with silicone sealant, and put the wicking cloth

directly on that, no aluminium sheet, however, was not confident of

being able to spread the sealant evenly over the large plywood surface.

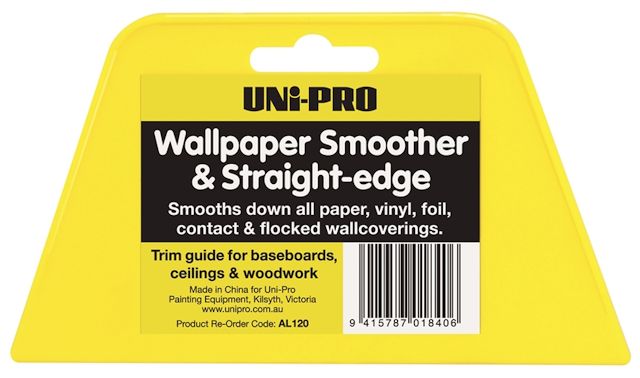

Another experiment was required. I found something at Bunnings that looked like it might do the job:

https://www.bunnings.com.au/uni-pro-wallpaper-smoother-and-straight-edge_p1661659

Hey, it works beautifully, was able to spread the sealant thinly over

a test piece of plywood. Note that the edge is not sharp, it is

rounded, which is I think the key to the nice spreading.

Wood and glass substrates

This photo shows the next experiment, putting the sealant onto various surfaces:

On the left is an old glass ashtray, two deposits of sealant, on the

left first smeared margarine, on the right applied the sealant directly

to the glass.

At the top is a piece of radiata pine, with sealant applied, from the

left: to the wood, a small amount of coarse sanding (across the grain)

and a small amount of fine sanding.

On the plywood, used the wallpaper smoother to apply the sealant. Then waited a couple of days.

Test results

The margarine on glass worked, the sealant did not adhere at all.

Probably there are many greases that would have the same effect,

including spray-on types.

Direct to the glass -- oh wow, it sure did bond. I guess that it is

the acidic curing that achieves such a superb bond. Was unable to lift

the silicone, without tearing it.

The radiata pine, bonding is good, but still able to lift it, with

some effort. Sandpapering might have improved the bonding slightly.

Being acidic-curing does not do anything with wood, and neutral-curing

would be just as good, I think. Bonding takes place by the sealant

getting into the tiny grooves on the surface of the wood.

On the plywood, adhesion is the same as for the pine. Well, it is the

same type of wood. Adhesion is good, sufficient I think to do this for

prototype #2.

However, for the second prototype, I am thinking of using MDF (Medium

density Fibreboard), rather than pine, partly because it is cheaper.

There are many grades of MDF, some premium types are water resistant.

Bunnings site does not say, but it is probably a cheap type. But that's

OK, the MDF will not be getting wet. I bought this:

https://www.bunnings.com.au/16mm-standard-mdf-600mm-x-900mm_p0590044

Today, applied the silicone sealant over a small area of the board,

will let it cure for a couple of days. Not sure what to expect, as the

surface is finer-grained that the plywood.

EDIT 2019-05-26:

Wow, the sealant bonds to MDF extremely well. Unlike the pine, it would

not lift off, I had to use a spatula and virtually grind it off in tiny

pieces. Although the MDF surface looks smooth, it does have tiny pores,

which are obviously providing good purchase for the sealant.

Note, this good bonding may not apply to all types of MDF, as some have a wax coating for water resistance.

EDIT 2019-05-29:

As adherence of the silicone sealant to pine was mediocre, I conducted a

further test, sandpapering the surface, with 60-grip (coarse) and

40grit (very coarse) sandpaper:

...no discernible improvement over non-sandpapered surface, it is sticky onto the pine, but fairly easy to peal off.

EDIT 2019-0530:

More bonding testing here:

http://bkhome.org/news/201905/silicone-on-silicone-and-silicone-on-pine.html

Tags: nomad