Global IP TV Panel updated 2025MK2

ETP has updated this:

https://forum.puppylinux.com/viewtopic.php?t=689

I have updated the PET, see commit:

https://github.com/bkauler/woofq/commit/0c1b869766074815cfb45418c94276d1153ba730

Tags: easy

snd_soc_avs blacklisted again

In Easy Daedalus, have updated to the 6.12.x kernel, but no joy with Intel AVS sound. Here are a couple of earlier blog posts:

- Intel sound avs driver still too immature — February 02, 2025

- Linux kernel 6.12.12 configured without AVS and Xe — February 03, 2025

- Kernel 6.12.19 compiled for Daedalus with AVS enabled — March 16, 2025

Kernel 6.12.19 is in Daedalus 6.6.5, the current release. Federico has reported AVS broken:

https://forum.puppylinux.com/viewtopic.php?p=146430#p146430

Oh well. I've blacklisted the snd_soc_avs.ko kernel module, see commit:

https://github.com/bkauler/woofq/commit/1d6119019edd75e9d115463ac9c6bc395426ea16

I suppose, next time compile the 6.12.x kernel, will go back to

disabling AVS entirely.

Tags: easy

Meanderer front suspension plates assembled

Continuing the Meanderer trike project. An earlier post showed construction of the front suspension plates:

- Meanderer trike front suspension plates — March 19, 2025

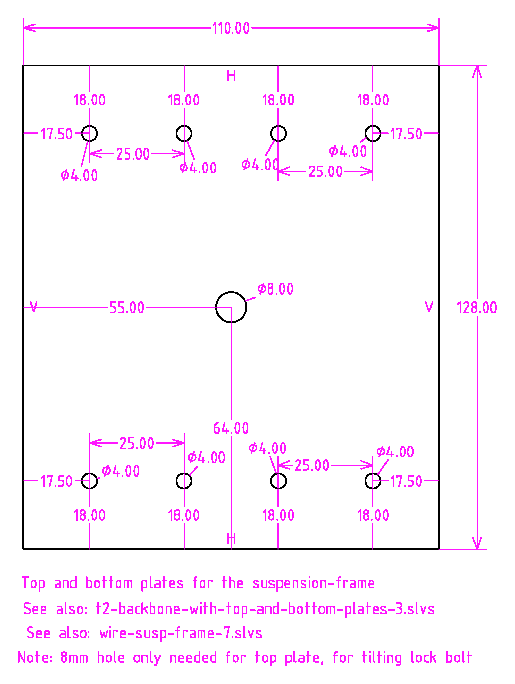

Those plates are going to slide onto the 50x50x3 square tube, that is the backbone of the trike. The plates assembly will have top and bottom plates; see drawing:

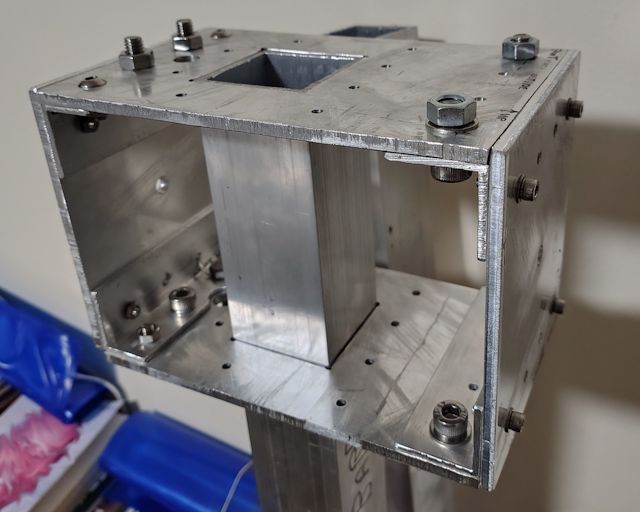

Used 25x25x3 angle to bolt the plates together. Carefully held while drilling holes:

Assembled, held together temporarily with bolts, checking that it is all symmetrical and slides over the square tube:

This framework will slide down to a cutout section of the square tube. The cutout is for implementing the leaning mechanism; if you don't want leaning, then no need for this cutout. The earlier blog post linked-to above, shows dimensions of the cutout; two of them actually.

I marked out the cutouts, then drilled some holes as starting points for the jigsaw:

...used a triangle file to create more space to insert the jigsaw blade; however, that is not really necessary. A round hole big enough to insert the blade is all that is required. Here are both holes cutout:

Obviously, these cutouts have seriously weakened the backbone, so the suspension-frame assembly is going to have re-strengthen it.

The square tube has a wall thickness of only 3mm. Components of

the tilting mechanism are going to be bolted to the underneath

side of the square tube, screwed on with m5 or m6 bolts. There

will be threads tapped into the square tube, but the wall

thickness of only 3mm will not be an adequate depth for the

thread. So, decided to insert plates inside the square tube; photo

of plates before insertion:

The plates are 200x43.5x3 mm. I drilled 4mm holes in the square tube, with the idea of pop-riveting the plates in place. However, holding them in place while pop-riveting is tricky, so instead decided to glue them in place with epoxy resin -- which I have done today.

Note, inserted one of those plates going toward the front of the

trike, the other two toward the rear. Bit tricky inserting the

third one; it probably isn't needed anyway.

Tomorrow will drill the 4mm holes and permanently hold those plates in place with pop rivets. Should not have drilled those holes beforehand, as wanted a very flat surface on which to epoxy the plates. Anyway, it is OK. Reiterating; those plates are on the inside.

Tomorrow, might epoxy a couple more plates on the top-inside; will post about that.

Have not done much on the Meanderer trike project for the last couple of weeks due to the eyelid operation. But on the mend, so have started going to the Men's Shed again and progressing with the project.

Here are the SolveSpace files for side and top and bottom plates (gzip compressed):

https://bkhome.org/news/202504/images/wire-susp-frame-7.slvs.gz

https://bkhome.org/news/202503/images/wire-susp-frame-top-and-bottom-plates-1.slvs.gz

Onward ho!

Tags: light

Refine fix Exec line in .desktop has quotes

Previous post about this:

- Fix Exec line in .desktop file has quotes — April 01, 2025

Have refined some more, see github:

https://github.com/bkauler/woofq/commit/6f66cd8cd7c1a3ece82d303e228445dcba552440

Tags: easy

Fix Exec line in .desktop file has quotes

Alfons reported, installed gSmartControl via PKGget in Easy Daedalus 6.6.4. After updating to Easy Daedalus 6.6.5, the menu entry for gSmartControl had disappeared; /usr/share/applications/gsmartcontrol.desktop had been deleted.

When there is a version update, /sbin/fixlayers in the initrd runs, and one thing it does is check the .desktop files are still valid. It looks at the "Exec=..." line and checks that the executable is still there.

In the case of gSmartControl, this is the Exec line:

Exec="/usr/bin/gsmartcontrol-root"

...oh man, no one puts the Exec parameter in quotes! In all the years I have worked with .desktop files, never encountered this. Yes, I suppose it is theoretically legal.

/sbin/fixlayers got thrown by the quotation character. I have put in a fix:

https://github.com/bkauler/woofq/commit/fd91f6e876ae3d6191043585ed0e6b37111de9c3

Tags: easy

sudo-sh handle more parameters

Forum member Caramel posted about this limitation:

https://forum.puppylinux.com/viewtopic.php?t=14098

Solved, but solved the lazy way, just extending code already known to work. sudo-sh is now version 1.5, source here:

https://distro.ibiblio.org/easyos/source/alphabetical/s/

Tags: easy

PKGget tweaks

I'm running Easy Daedalus 6.6.5, and used PKGget to install SeaMonkey PET package. PKGget only offered to download the PET from ibiblio or nluug repositories. I have added aarnet:

https://github.com/bkauler/woofq/commit/377244947dc4b1a60a1ac9b66745b94456f9aed5

PKGget asked if SeaMonkey is to be installed to run as the root user or non-root. SeaMonkey is a suite, with browser, composer, mail and address-book modules, and I think it complicates things if it is installed non-root. Therefore constrained to run as root only:

https://github.com/bkauler/woofq/commit/8ee2ac3ec0610c0bc18abbd73a01fa9278f29cde

Tags: easy

EasyOS Daedalus-series version 6.6.5 released

Version 6.6.4 was released on March 11:

- EasyOS Daedalus-series version 6.6.4 released — March 11, 2025

Highlights of version 6.6.5, since 6.6.4:

- sudo-sh fix — March 29, 2025

- More Limine Installer fixes — March 27, 2025

- EasyAPT launch from menu — March 17, 2025

- NeoAPT simplified replacement for apt utility — March 16, 2025

- Kernel 6.12.19 compiled for Daedalus with AVS enabled — March 16, 2025

Release notes:

http://distro.ibiblio.org/easyos/amd64/releases/daedalus/2025/6.6.5/release-notes.htm

Download:

http://distro.ibiblio.org/easyos/amd64/releases/daedalus/2025/6.6.5/

Beginner's notes:

http://distro.ibiblio.org/easyos/amd64/releases/daedalus/2025/6.6.5/readme.htm

Feedback welcome at the forum:

https://forum.puppylinux.com/viewtopic.php?p=145650#p145650

Tags: easy