Swing-arms for Meanderer trike

Continuing the build-from-scratch recumbent full-suspension leaning tadpole trike project, codenamed the "Meanderer", here are the previous two blog posts:

- Useful aids for drilling and tapping — April 14, 2025

- Meanderer front suspension plates assembled — April 07, 2025

Those front suspension plates will have swing-arms attached, and shock-absorbers and wheels. There are many different ways that the swing-arms can be constructed; my previous trike project is welded steel:

Or, you could just bend a steel or aluminium bar; actually, that would be the easiest and simplest method, but I was reluctant to bend aluminium. It depends on the formulation of the aluminium; some types are strong but brittle, some are malleable. For the brittle type of aluminium, a flame is required to heat the aluminium bar before bending.

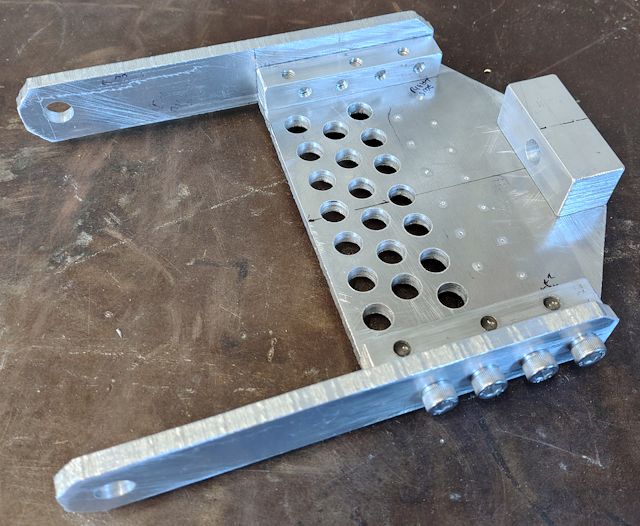

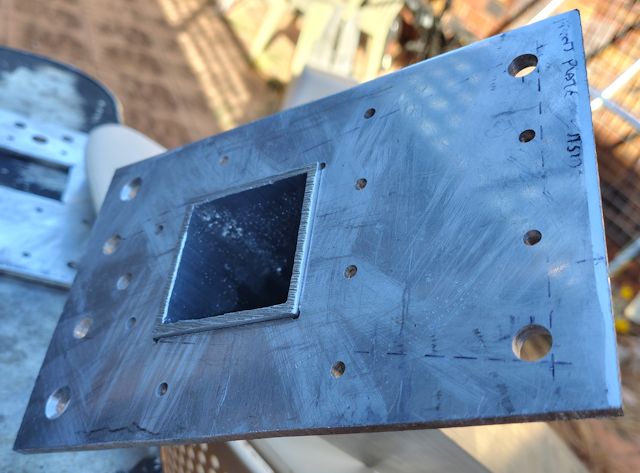

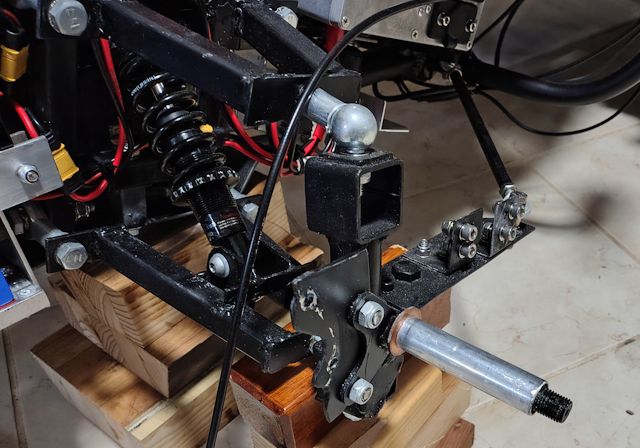

Anyway, I decided to contruct the swing-arms out of solid aluminium, no bending, pieces bolted together. It is taking me a long time to construct and the arms are quite heavy. Firstly, showing the end result:

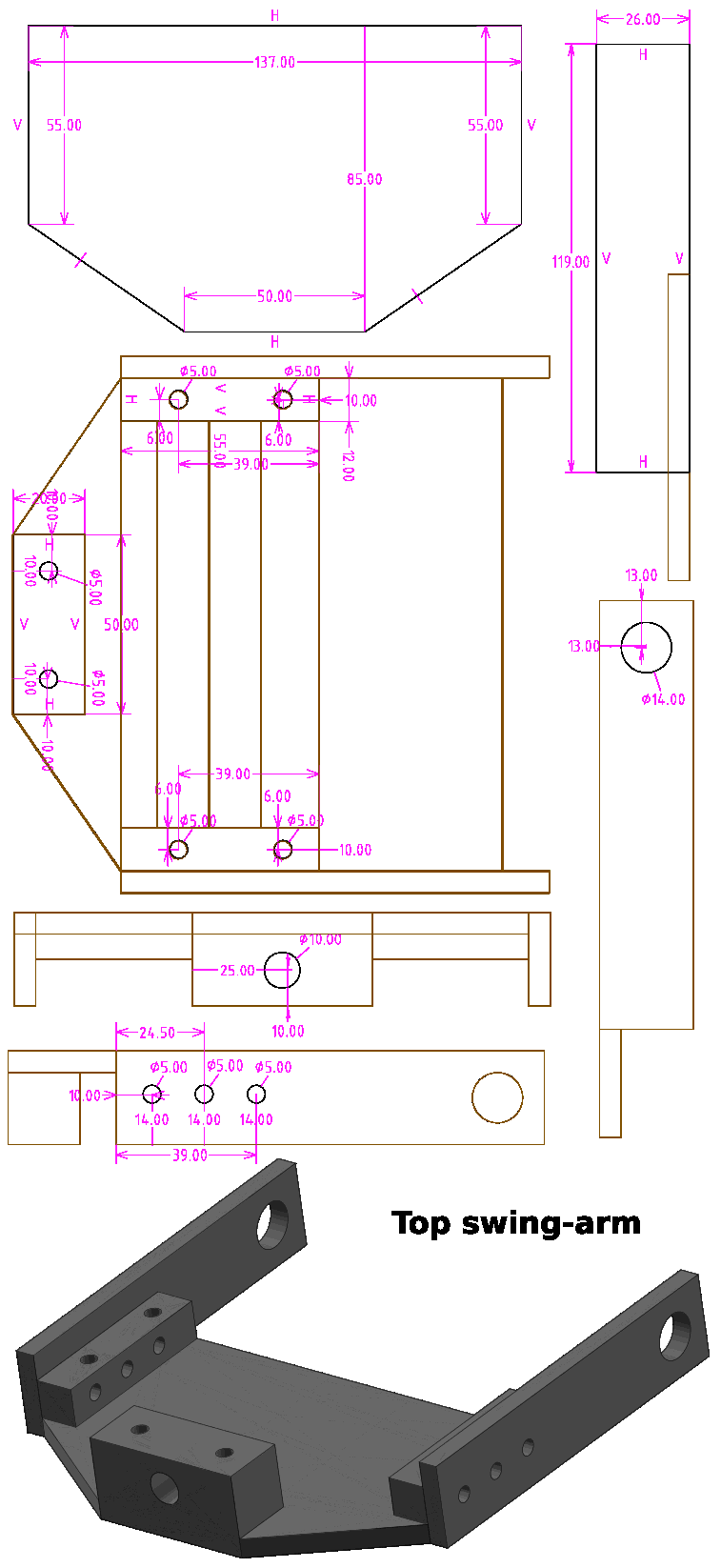

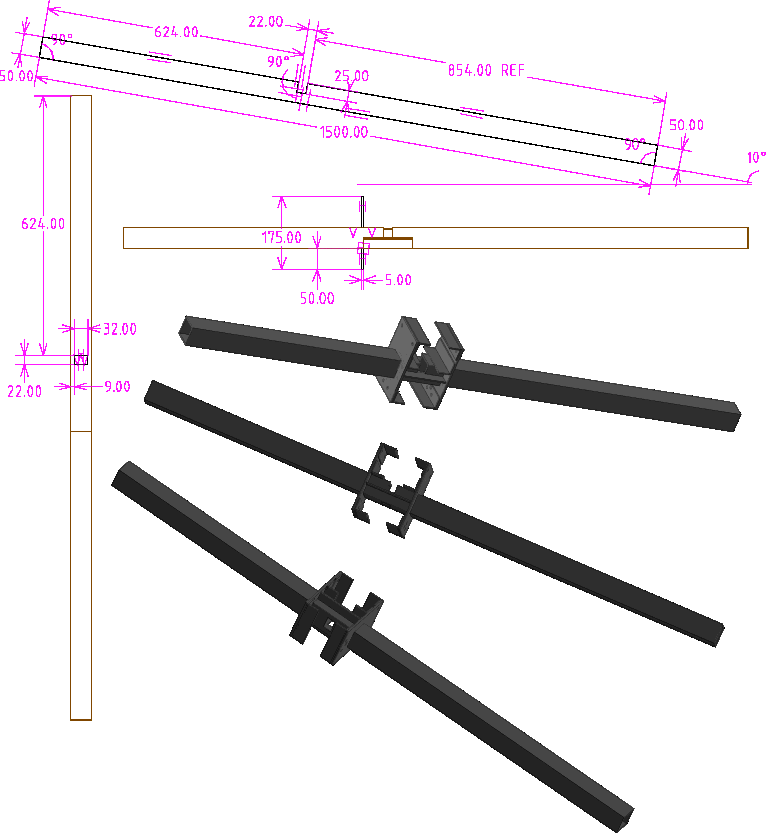

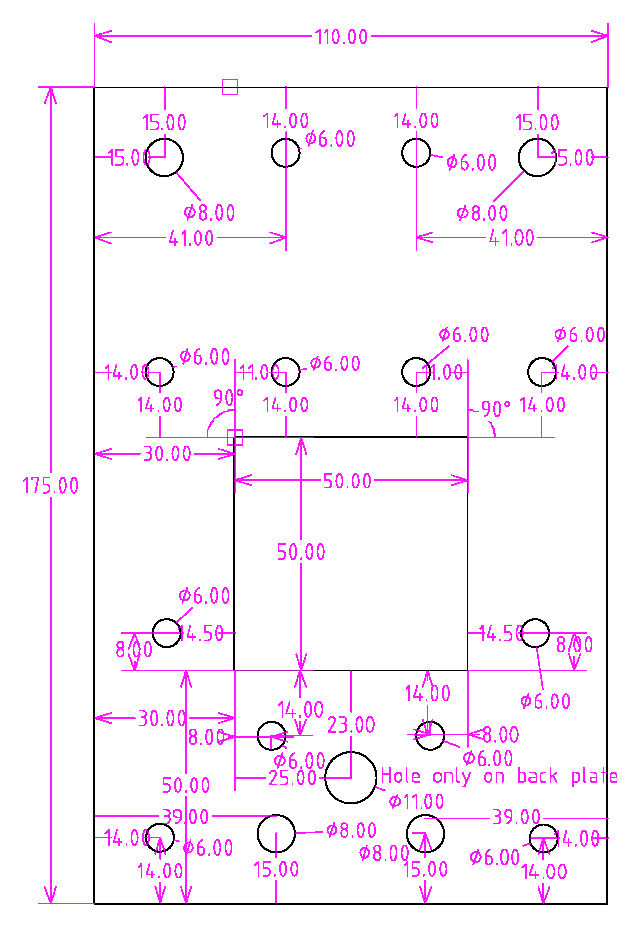

I bought a couple of 200x300mm 6mm thick aluminium sheets off eBay, and the square rod is 12x12mm and 20x20mm from Bunnings here in Australia. The bolts are m6. Here are the plans, firstly the top swing-arm:

One change though; the large holes at the pivot-points are shown as 14mm -- I changed my mind and drilled only 10mm -- will explain that later. Here is the SolveSpace file, gzip-compressed:

Here is the drawing for the bottom swing-arm:

...same thing, the 14mm diameter holes were only drilled to 10mm. Here is the SolveSpace file, gzip-compressed:

You will see in the final-result photo, lots of holes drilled in the 6mm sheet; that is to reduce weight. In the bottom swing-arm, have left an area without holes, as two pieces of angle will need to be bolted on for the shock-absorber. The exact placement of that angle depends on the length of the shock-absorbers, which is not yet finalized.

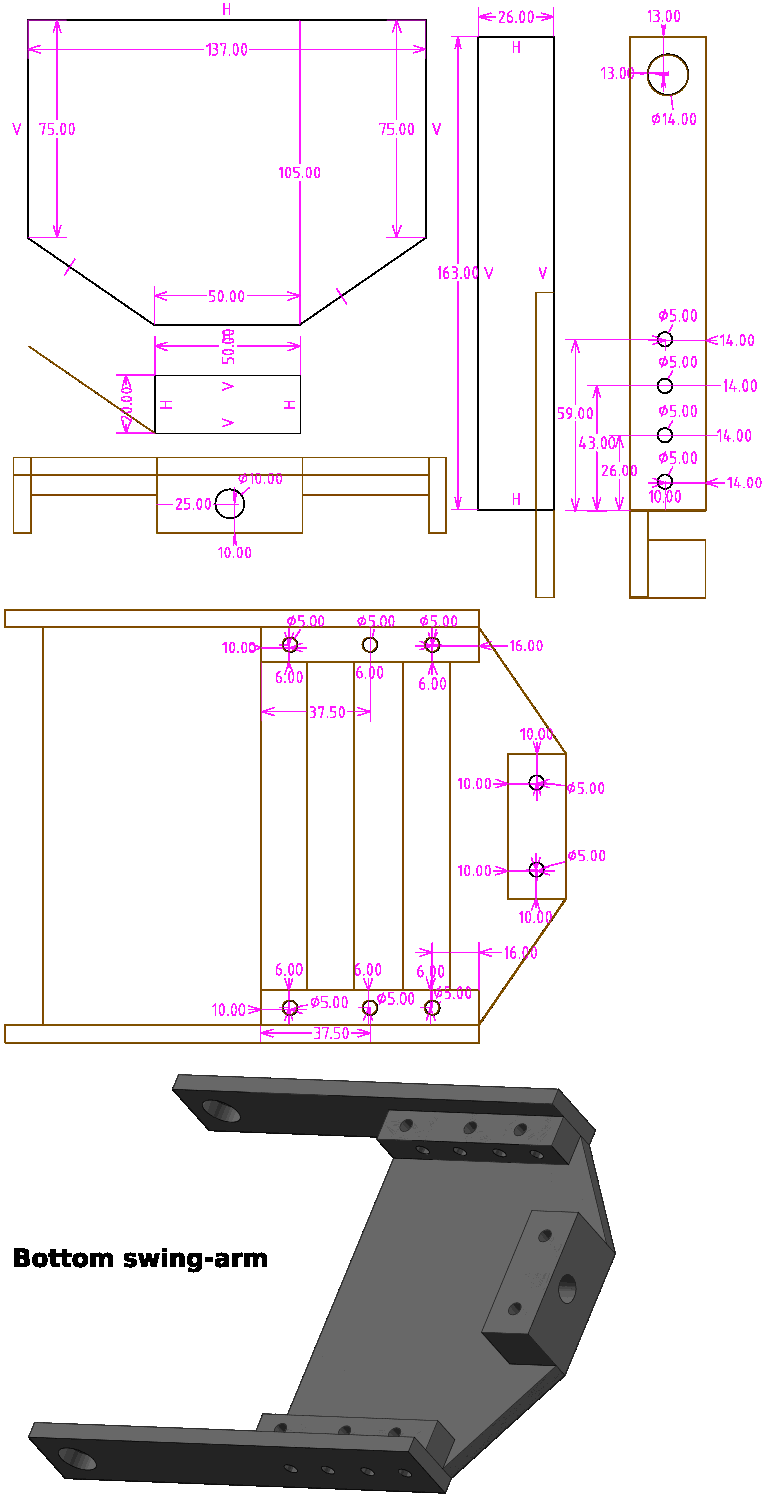

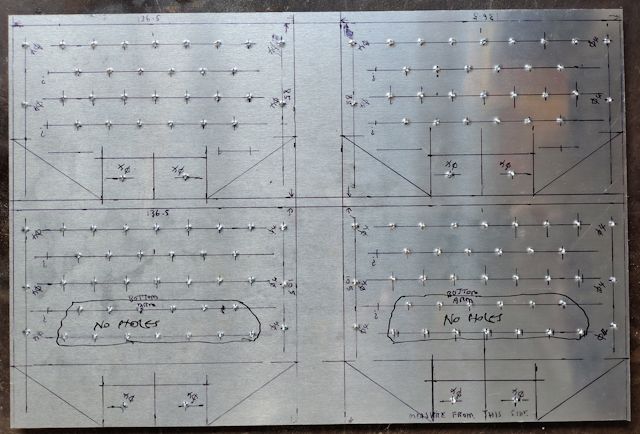

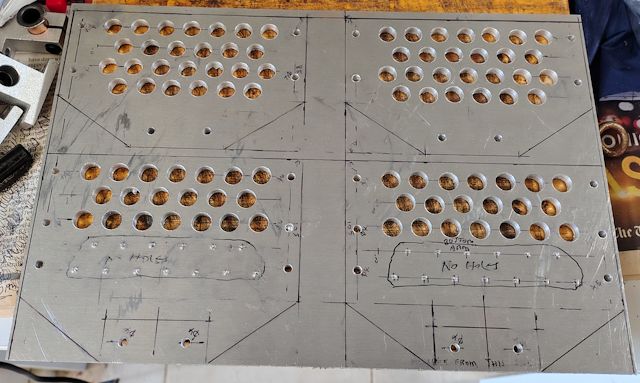

The way I constructed was to mark out all four swing-arm plates on the 200x300 sheet and centre-punch for the holes:

Used a 4mm drill bit, for pilot holes, followed by 10mm for the weight-reducing effort:

After the pieces are cutout, threads have to be tapped into the square rod, and clamps were required:

|

|

...drilled with an battery-electric hand drill, 4mm pilot holes. For the square rod, drilled-out to 5mm, then tapped for m6 thread, pitch 1.0mm. 1.0 is the standard pitch for m6.

In retrospect, what do I think about this method of constructing

the swing-arms?

Heavy, and taking awhile, but OK I suppose. There is an advantage, as if decided to change the design of those side-bars, such as make different length or different hinge design, can just unbolt and replace. But then, constructing by bending an iron bar is simple and quick, if want to make a change.

Anyway, have gone down this path, and the swing-arms will do the job.

Probably next-up will be to get back onto building the suspension

plates, attached to the 50x50mm square tube backbone of the trike.

Then the hinges can be made to attach the swing-arms.

Tags: light

Useful aids for drilling and tapping

Continuing the Meanderer trike project, previous post:

- Meanderer front suspension plates assembled — April 07, 2025

In this post, I am showing some aids for the project, in fact,

the first two are required.

1: Hole-reamer

A core part of the tilting mechanism is a 10mm diameter rod. This has to slide through holes that I have drilled in aluminium. The problem is that a 10mm drill-bit is actually slightly under 10mm, and usually the resultant hole is less than 10mm. Hence, the rod won't fit.

Just needs a tiny amount shaved off the hole; enter the reamer. I bought this set from eBay:

https://www.ebay.com.au/itm/196502934905

I bought a set, as will be needing other sizes, such as 14mm and

6mm.

These are operated by hand, not with a drill, and the lever from a tap-and-die set is required to turn the reamer. It is recommended to apply some oil. These are cheap, fine for aluminium, but I don't know how long they will last if reaming steel.

2: 3-piece tap-set

On the topic of a tap-and-die set, yes, I have one, so does the Men's Shed. However, the taps are just one of each size and pitch. A 3-piece set is one size and pitch, but three different taps; one for getting-started, then a normal one, then one for tapping the thread as far down a dead-end hole as possible. I bought 5mm, 6mm and 8mm sets from eBay:

https://www.ebay.com.au/itm/192442744976

Very handy, especially the getting-started one. Again, a lever from the tap-and-die set is required, and it is operated by hand. The tap-bit has to be held exactly vertical to the work-piece, and that is tricky when getting started, so the getting-started one is very helpful.

3: Drill-tap combination bit

This is not essential, just nice to have. You don't have to find the correct-size drill bit, prior to tapping the thread, as this combines both in one drill bit. I bought from AliExpress (both the B-short and A-long):

https://www.aliexpress.com/item/1005005955702010.html

Probably a good idea to watch a couple of YouTube videos on how to use these correctly. For example, the work-piece must be no thicker than the "drill" part of the drill-bit. Recommend to apply oil. These can be used with an electric hand-drill or a drill-press. These cheap ones OK for aluminium, not so good for steel. If use an electric hand-drill, putting it into reverse to extract the drill-bit might not be a good idea, as there is a risk of a cross-thread -- instead, remove the drill-bit and reverse-thread by hand -- which would be a bit tedious.

Here are some YouTube videos of these combination bits:

https://www.youtube.com/watch?v=SYtKzLjT5Lg

https://www.youtube.com/watch?v=_ia5P3u8uBQ

These three are very useful aids to have in any home

workshop!

Tags: light

Meanderer front suspension plates assembled

Continuing the Meanderer trike project. An earlier post showed construction of the front suspension plates:

- Meanderer trike front suspension plates — March 19, 2025

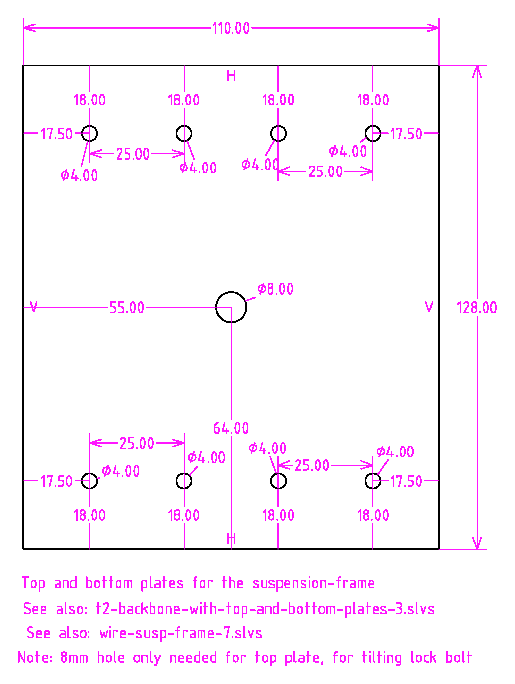

Those plates are going to slide onto the 50x50x3 square tube, that is the backbone of the trike. The plates assembly will have top and bottom plates; see drawing:

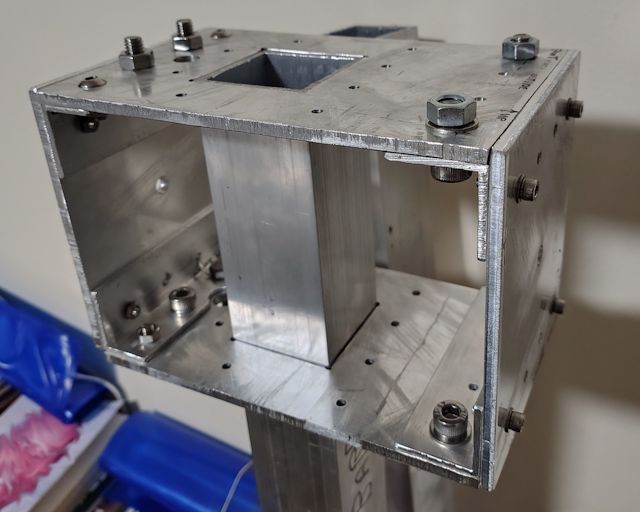

Used 25x25x3 angle to bolt the plates together. Carefully held while drilling holes:

Assembled, held together temporarily with bolts, checking that it is all symmetrical and slides over the square tube:

This framework will slide down to a cutout section of the square tube. The cutout is for implementing the leaning mechanism; if you don't want leaning, then no need for this cutout. The earlier blog post linked-to above, shows dimensions of the cutout; two of them actually.

I marked out the cutouts, then drilled some holes as starting points for the jigsaw:

...used a triangle file to create more space to insert the jigsaw blade; however, that is not really necessary. A round hole big enough to insert the blade is all that is required. Here are both holes cutout:

Obviously, these cutouts have seriously weakened the backbone, so the suspension-frame assembly is going to have re-strengthen it.

The square tube has a wall thickness of only 3mm. Components of

the tilting mechanism are going to be bolted to the underneath

side of the square tube, screwed on with m5 or m6 bolts. There

will be threads tapped into the square tube, but the wall

thickness of only 3mm will not be an adequate depth for the

thread. So, decided to insert plates inside the square tube; photo

of plates before insertion:

The plates are 200x43.5x3 mm. I drilled 4mm holes in the square tube, with the idea of pop-riveting the plates in place. However, holding them in place while pop-riveting is tricky, so instead decided to glue them in place with epoxy resin -- which I have done today.

Note, inserted one of those plates going toward the front of the

trike, the other two toward the rear. Bit tricky inserting the

third one; it probably isn't needed anyway.

Tomorrow will drill the 4mm holes and permanently hold those plates in place with pop rivets. Should not have drilled those holes beforehand, as wanted a very flat surface on which to epoxy the plates. Anyway, it is OK. Reiterating; those plates are on the inside.

Tomorrow, might epoxy a couple more plates on the top-inside; will post about that.

Have not done much on the Meanderer trike project for the last couple of weeks due to the eyelid operation. But on the mend, so have started going to the Men's Shed again and progressing with the project.

Here are the SolveSpace files for side and top and bottom plates (gzip compressed):

https://bkhome.org/news/202504/images/wire-susp-frame-7.slvs.gz

https://bkhome.org/news/202503/images/wire-susp-frame-top-and-bottom-plates-1.slvs.gz

Onward ho!

EDIT 2025-04-11:

Cutout plates for the sides and top also, each about 70mm long.

Here they are glued in:

I used a two-part epoxy from Red Dot, a chainstore in Australia. It sets super-fast, tacky in about a minute, despite the packaging claiming remains usable for 5 minutes. Hmmm, can't find it on the Red Dot website -- the one I bought is two separate 12.5ml tubes. Very much prefer slow-setting resins.

Tags: light

VeMoo leaning tadpole trike

I'm always interested in new tadpole trike developments. At one time I looked around for enclosed or semi-enclosed tadpole trikes (or quads), and in 2023 posted this report on the Pedilio and Veemo:

- Enclosed pedal-powered recumbent in production — November 22, 2023

So many of these startups claim to be starting production "soon",

or to have started limited production. But then, years later, they

have faded away. Just a quick glance at the Veemo site, it looks

like they have reached production.

I recently discovered another startup, the VeMoo trike; this one is particularly interesting, as it is a leaning design and also full-suspension. It is partially enclosed. Here is the website:

![]()

The VeMoo is intended to be in production in 2025. They are taking pre-orders, but I don't know the price.

I very much want to know how the steering and leaning works, but cannot find the precise details. There are videos, but they don't show much detail:

https://www.youtube.com/@VeMoo_Mobility/videos

However, I got a clue how the leaning works from this video by the "Laidback Bike Report" of the VeMoo at Spezi 2024 exhibition:

https://www.youtube.com/watch?v=mf6iN0zQ8Aw

The guy showed how it tilted, just by pushing it sideways. This means that it is a weight-controlled leaning; so you shift your weight to the side and it will lean. This is a "Type 1" leaning mechanism, that I posted about recently:

- Another look at tilting tadpole trike designs — February 25, 2025

However, the website describes it as a "pendulum suspension". From this I deduce that when sitting in it, it will have a natural tendency to stay vertical. But, lean to the side and it will tilt.

I cannot say how effective this leaning mechanism is; anyone who

has ridden one, let me know! You can post in the comments section

of my YouTube channel, or send me an email.

Tags: light

Meanderer trike project intro video

Previous blog post in the new "Meanderer" leaning full-suspension build-from-scratch DIY tadpole trike project:

- Meanderer trike front suspension plates — March 19, 2025

The intention is to make videos on YouTube as the project progresses; to get the ball rolling, I have created a brief intro video, that outlines what the project is about.

Don't expect much though; this is the first time that I have

video-ed myself. Used my phone selfie-camera, and when played

back, realised two main faults; firstly that I should have been

looking at the camera not at the screen, and secondly shouldn't

have wobbled my head around so much.

Anyway, here it is:

"Meanderer leaning full-suspension tadpole trike PART1"

https://www.youtube.com/@meanderinglight/videos

I'm not bothered about my photogenic lack, nor faulty technique, as this is introducing a technical project, and in future videos most of the time the camera will be pointed at the work underway, rather than myself.

Did start to learn how to use Flowblade video editor, but haven't

progressed very far.

Tags: light

Meanderer trike front suspension plates

Previous blog post in Meanderer trike project:

- Front wheel hubs for tadpole trike — March 12, 2025

The front of the trike will have suspension, with swing-arms (also known as A-frame or wishbone arms) and shock-absorbers. The swing-arms will hinge on two plates attached to the frame of the trike. The frame is a 25x25mm square tube, 3mm wall thickness. The plates are 110x175mm sheet, 5mm thickness. There will be extra bracing with angle, as illustrated:

More construction details will be revealed, but for now, contructing just the two plates. They have holes and 50x50mm cutout:

...regarding those 6mm holes; in fact, I used a 4mm drill bit, the intention being to later tap a thread for m6 bolts.

In an earlier blog post, there is a link to where I purchased the

5mm thick sheet. However, in retrospect I would have bought 6mm

sheet, as that is more common and discovered available locally at

a reasonable price.

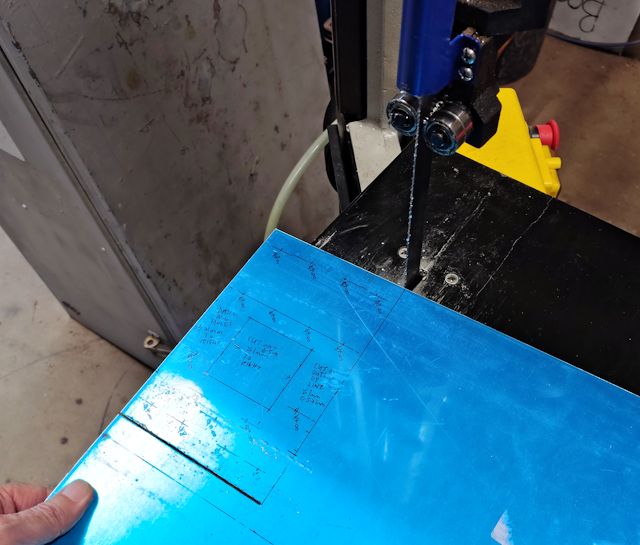

I marked out the holes and cutout, then cut the plates on a metal bandsaw:

...yes, I know this project is intended to be do-able by anyone in their home workshop; a handheld jigsaw does the job OK also. In fact, I found that a jigsaw was the best choice for the 50x50 cutout.

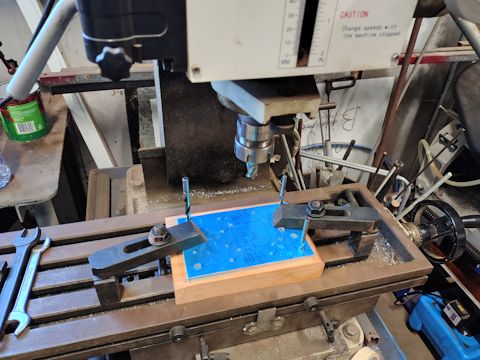

Then put the two plates together, firmly clamped on a block of wood, and drilled the holes with a hand drill (after centre-punching):

...took the precaution of driiling 2.5mm pilot holes first, for

greater accuracy. For the 8mm holes, it would also be good

practice to drill another intermediate hole, say 5.5mm. The reason

is, large drill bits tend to wander off-centre, and a pilot hole

keeps them centred.

The 50x50 cutout... expected that to be tricky. We started to do it on a large metal router at the Men's Shed:

...no, not appropriate for a DIY guy in the home workshop! Besides, we decided that it is a clumsy way to do it. Instead, used a hand jigsaw. Firstly, took off the protective plastic, then re-marked the 50x50 cutout:

...the four 8mm holes are the suspension hinges for the

swing-arms, and the 50x50 cutout has to be symmetrical. I drew

lines on the outside of the 8mm holes, to help with measuring

symmetry.

I had previously drilled 3mm holes in the corners of the cutout, which we thought might be useful. But in retrospect, probably not. Or maybe just smaller, like 2mm.

Anyway, got the cutout re-marked, then drilled 10mm holes in opposite corners, as close to the marked lines as possible. Then used a square file to make the corners square, for insertion of the jigsaw blade. I used one of the jigsaws in the Men's Shed; it already had a blade in it, didn't know if for wood or metal, but it did have fine teeth, which I wanted:

|

|

...yes, nice cutout. Just cut one plate, then used that to re-mark the second.

A bit of fine-tune filing was required, then it was able to slide snuggly onto the 50x50 tube:

...notice those two holes in the bottom corners; countersunk. The

two closer-in are the 8mm holes for the swing-arms, the two outer

holes were supposed to be drilled with a 4mm drill bit, for later

tapping for m6 bolts. However, a lapse in concentration and I

drilled 6mm holes. So decided instead they will be countersunk

bolts.

So, what's next...

Tags: light

Front wheel hubs for tadpole trike

Continuing the new "Meanderer" build-from-scratch recumbent full-suspension leaning tadpole trike project, here are recent posts:

- Universal-joint for Meanderer trike — March 03, 2025

- Progress planning The Meanderer — March 01, 2025

- Steering swivel-coupling for new trike project — February 28, 2025

- Another look at tilting tadpole trike designs — February 25, 2025

- Planning a recumbent trike built from scratch — February 21, 2025

Using bicycle parts where possible, is good; however, there is a problem with the front wheels. A bicycle front wheel has support on both sides of the axle, whereas only on one side on a trike. This is a problem; we need a certain type of bicycle wheel hub, known as a "thru hub". This has a shaft, or axle, that goes right through, usually of 12mm, 15mm or 20mm diameter.

We really want the 15mm or 20mm axles, which is another problem, as they are only used in premium mountain bikes. So, finding that type of wheel secondhand might be difficult. Suitable wheels could probably be purchased from a bike shop, or maybe a cheap secondhand tadpole trike could be located.

My first trike project, now mostly completed, was a cheap trike that I modified, with front suspension, etc. I'll refer to it as my "current trike". It has wheel hubs for a 20mm thru-axle:

I got a bit confused, as this hub is only about 92mm wide, whereas looking online, available hubs are 100mm, 110mm, or 135mm wide. Nothing under 100mm. So I bought a couple, 15x100 and 20x110, to examine. After they arrived, I realised something; they are not "really" that wide.

To explain, here are photos of the hubs on my current trike:

And the inside:

...it looks very much like some extensions on both sides has been

removed. The width of the inner alloy tube is only 82mm, and total

width of the hub is 92mm.

Yes, the two hubs that I purchased have plastic extensions on both ends, extending the width to 100mm and 110mm. But, cut them off, and the with becomes 92mm and 84mm.

This is one that I purchased, 15x100, meaning 15mm diameter thru-axle and 100mm hub width, for AU$28.39 (plus 10% GST):

https://www.aliexpress.com/item/1005005254533680.html

The other, 20x110 32-hole, for AU$41.59 (plux GST):

https://www.aliexpress.com/item/1005008343824211.html

20mm axle hubs are somewhat rarer and much more expensive. Photo:

I reckon those plastic width-extenders could be cut shorter. So,

I plan to build the axle length on the Meanderer wheel knuckle for

a 92mm wide hub. That will handle all three of the above hubs.

Maybe make the knuckle axle a bit longer, and washers can be used

if required.

A note about a tadpole trike; we need to be careful about overall width. For the Meanderer, I want total width to be no more than 730mm, so as to fit through my front door, and motel doors when touring. So taking 10 - 15mm off the hub is important.

If you want to read more about mountain bicycle front wheel hub types:

https://www.bikeradar.com/advice/buyers-guides/mtb-axle-standards

Should also mention, there are axle diameter reducers available. I bought this one to evaluate, 20x100 to 15x100:

https://www.aliexpress.com/item/1005006596535497.html

Plan to build the wheel knuckles soon, and there will be a blog post when that happens.

Tags: light