Progress planning The Meanderer

I don't know if that name, "The Meanderer" will stick, for the new full-suspension leaning recumbent tadpole trike. Here are recent posts:

- Steering swivel-coupling for new trike project — February 28, 2025

- Another look at tilting tadpole trike designs — February 25, 2025

- Planning a recumbent trike built from scratch — February 21, 2025

...in the post of Feb 28, I posted plans for a swivel-coupling, then changed my mind and removed it. The swivel-coupling, or more correctly a universal-joint, needed a bit more thought. For other components of the trike, waiting on parts to arrive. So what can I build now? -- can build the swivel mechanism for the shock absorbers.

Getting the parts together, need various lengths of aluminium extrusion. Want 50x50x3 mm square extrusion, about 3 metres. Not available at Bunnings (our main hardware chainstore here in Australia), so looked online. Got a quote from one company, but this is a big company and 50x50x3 is sold in 6.5m lengths. They will sell by the metre, but about double the price. Then they wanted AU$150 to deliver, about a 50 minute drive away.

Hmmm. Found a local little family business; they had 50x50x3 in stock and were happy to sell by the metre, and very cheap. Pickup only, so I rode my ebike there:

...don't laugh! Was able to ride the bike with that load.

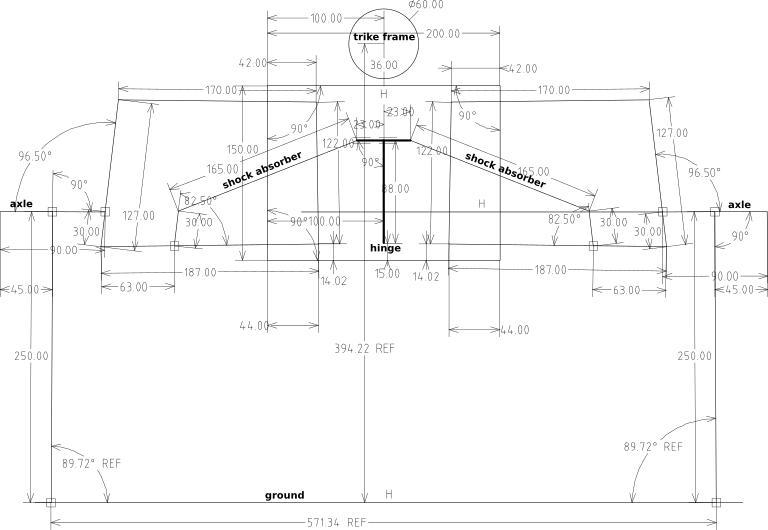

The proposed tilting is by a swivel-bracket where the shock absorbers join, see this blog post:

- Two-shock design with swinging steering linkage — November 18, 2023

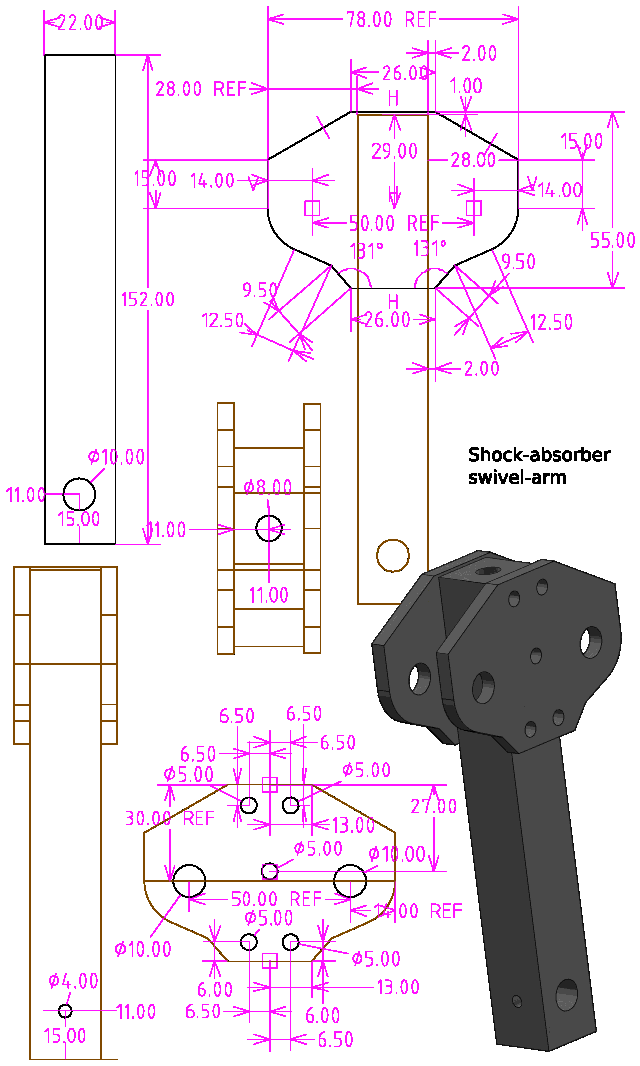

In SolveSpace, created a design for that swivel-bracket. Here it is:

EDIT 2025-03-05:

Following diagram and SolveSpace file have been updated:

https://www.aliexpress.com/item/1005004854415047.html

The diagram shows five holes of 10mm diameter. The four at the top will have brass bushes, to take 8mm rods for the shock absorbers. There are bushes available with 1mm wall thickness, and it is a good idea to put those in, so as to have replaceable wear surfaces, rather than wearing the aluminium holes. The 10mm hole at the bottom of the post will not require a bush.

Have the 22x22, but want sheet 5mm thick; only have 3mm. Have some 5mm on order; have to wait until it arrives.

A note about the spacing of the two sheets. The required spacing

depends on what shock absorbers are used. I'm not sure, but I

think that motorcycle shock absorbers are 19mm, whereas those on

bicycles and scooters are 24mm.

Just remembered also; the bicycle shock absorbers require 8mm bolts, the motorcycle type require 10mm. At least, for ones that I have looked at.

Here is the SolveSpace file, gzip-compressed:

https://bkhome.org/news/202503/images/t2-susp-swivel-2.slvs.gz

In the above diagram; the 10mm hole at bottom of the post will have a 10mm rod through it. There will need to be grub screws either side, as the swivel-bracket is required to be locked to the rod. Likely I will drill either 4.2mm holes for a m5 bolt, or 5.0mm holes for a m6 bolt (the diagram shows 4.0mm). Probably the smaller. Note, the rod is required to be locked to the swivel-arm as that is part of the tilt control; will probably drill the 4.2mm holes slightly into the rod, before threading, so as to have very positive locking of the rod.

The 5.0mm holes are for m6 bolts, so will need to be drilled-out

to 6mm through the sheets, and tapped in the post.

Oh, and to round off the explanation a bit more; that central

post has a 8mm hole right through, and at the top a m8 bolt can be

slid into it to lock tilting. There will be aluminium sheet above

the swing-arm, with a 8mm hole; slid the bolt through that and

into the post, then no more tilting. Just in case the rider

doesn't want the tilting mechanism, that is how easy it will be to

disable it.

Tags: light