Universal-joint for Meanderer trike

Earlier posts on this new trike built-from-scratch project:

- Progress planning The Meanderer — March 01, 2025

- Steering swivel-coupling for new trike project — February 28, 2025

- Another look at tilting tadpole trike designs — February 25, 2025

- Planning a recumbent trike built from scratch — February 21, 2025

In the "swivel-coupling" post above, I did post plans for a swivel-coupling, or universal-coupling, but withdrew it. Have reconsidered, modified the plans, and here it is again...

Bought a little universal-joint off Aliexpress, for a 10mm shaft. These are available from many vendors:

However, not happy with it. There is some sloppiness in the movement, and I would like it to have replaceable bearings. Hence a design to make one...

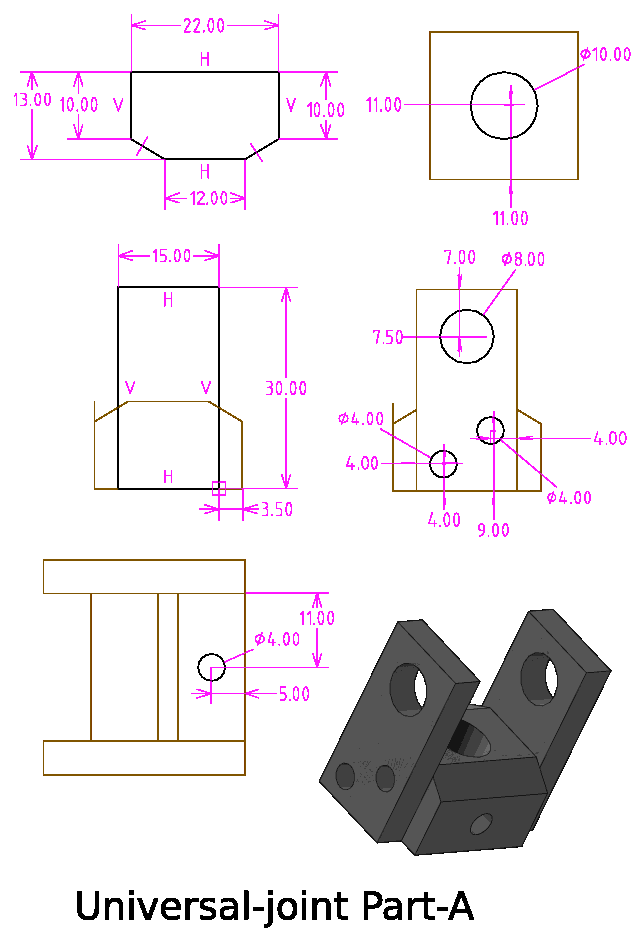

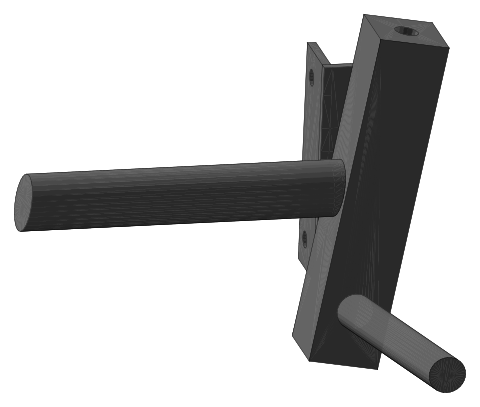

In SolveSpace, it is possible to create what is called an "assembly", multiple 3D components put together. However, I have found that to be very difficult. So, have designed the universal-joint in two parts, then mentally visualized how they would work when put together. Here is Part-A:

The aluminium sheet is 5mm thick; a couple of local stores only had 3mm, so I bought it at a premium price off Aliexpress:

https://www.aliexpress.com/item/1005003726781313.html

Though, likely there are local aluminium fabricators that would have 5mm offcuts. The main block of aluminium is the 22x22 square, that I provided a purchase link in the previous blog post.

The 8mm hole will have a brass flanged bush, the 12-8x6x6 from here:

https://www.aliexpress.com/item/1005005073792086.html

Actually, I have referred to the bushes as made of brass, but it is listed as "copper-based alloy"; whatever, it is very strong, not soft like copper, and has a different colour than brass.

One thing; to get sufficient flexibility, those square corners near the 8mm holes, will need to be rounded off. That will be easy enough; just cut off the corners and round off with a file.

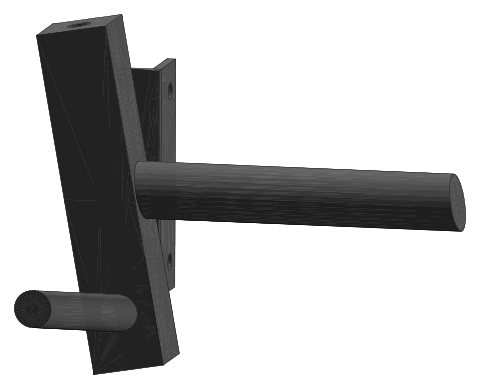

Here is Part-B:

Again, a piece of the 22x22 square aluminium.

I'm having to mentally visualize whether it will have adequate

flexibility; seems OK.

In the above diagram, the 5mm holes are for tapping a thread for

an m6 bolt. In the first diagram, the 4mm holes on the sheet will

be drilled out to 5mm, and in the main block tapped for an m5

thread. The m5 bolts will go through and bolt the sheets onto the

main block. There will be m5 grub screws to lock the 10mm rod.

Note, m5 standard thread has a pitch of 0.8mm and the required drill size is 4.2mm. So a 4mm drill bit is a bit small. Might have to experiment to cut a m5 thread in that smallish hole.

The 5mm thick sheet hasn't yet arrived; however, tomorrow can manufacture the three 22x22 main blocks (there will be two Part-A).

Here is the SolveSpace design, files renamed with a false ".gz":

https://bkhome.org/news/202503/images/t2-universal-joint-parta-2.slvs.gz

https://bkhome.org/news/202503/images/t2-universal-joint-partb-2.slvs.gz

Tags: light

Progress planning The Meanderer

I don't know if that name, "The Meanderer" will stick, for the new full-suspension leaning recumbent tadpole trike. Here are recent posts:

- Steering swivel-coupling for new trike project — February 28, 2025

- Another look at tilting tadpole trike designs — February 25, 2025

- Planning a recumbent trike built from scratch — February 21, 2025

...in the post of Feb 28, I posted plans for a swivel-coupling, then changed my mind and removed it. The swivel-coupling, or more correctly a universal-joint, needed a bit more thought. For other components of the trike, waiting on parts to arrive. So what can I build now? -- can build the swivel mechanism for the shock absorbers.

Getting the parts together, need various lengths of aluminium extrusion. Want 50x50x3 mm square extrusion, about 3 metres. Not available at Bunnings (our main hardware chainstore here in Australia), so looked online. Got a quote from one company, but this is a big company and 50x50x3 is sold in 6.5m lengths. They will sell by the metre, but about double the price. Then they wanted AU$150 to deliver, about a 50 minute drive away.

Hmmm. Found a local little family business; they had 50x50x3 in stock and were happy to sell by the metre, and very cheap. Pickup only, so I rode my ebike there:

...don't laugh! Was able to ride the bike with that load.

The proposed tilting is by a swivel-bracket where the shock absorbers join, see this blog post:

- Two-shock design with swinging steering linkage — November 18, 2023

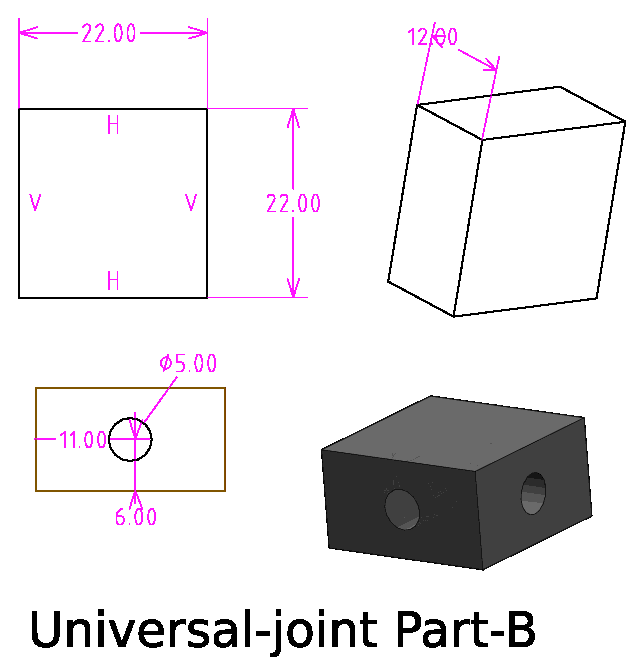

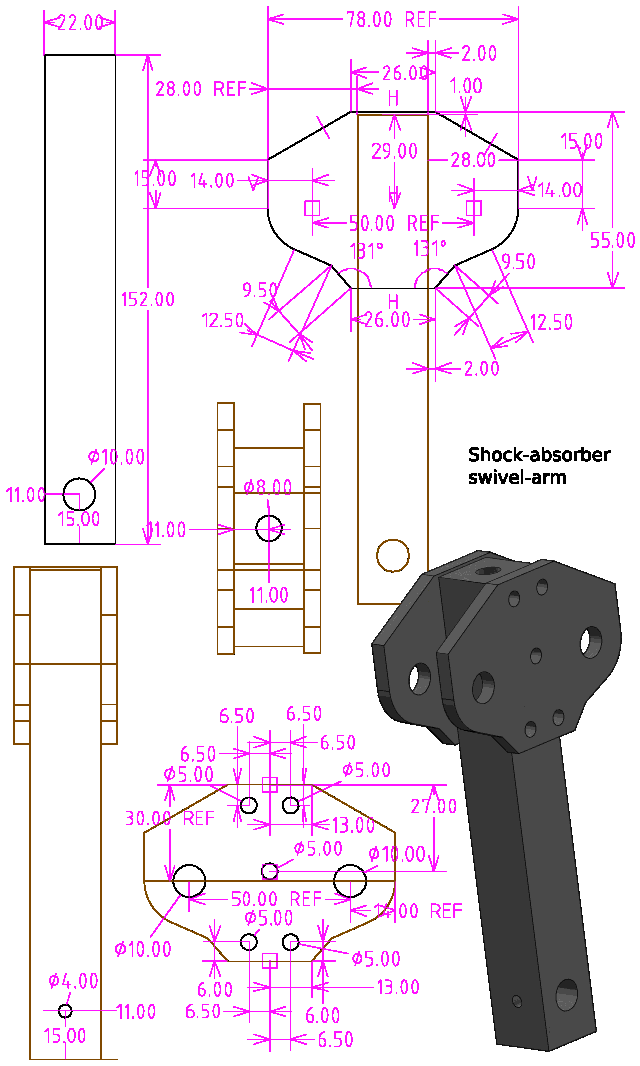

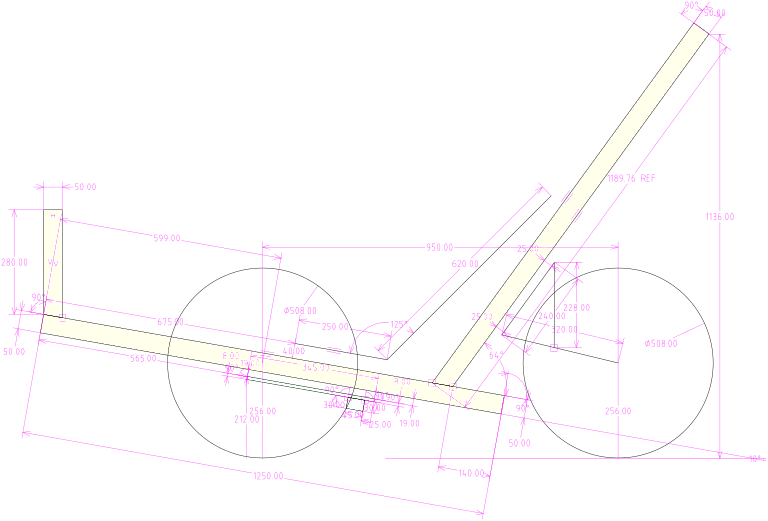

In SolveSpace, created a design for that swivel-bracket. Here it is:

EDIT 2025-03-05:

Following diagram and SolveSpace file have been updated:

https://www.aliexpress.com/item/1005004854415047.html

The diagram shows five holes of 10mm diameter. The four at the top will have brass bushes, to take 8mm rods for the shock absorbers. There are bushes available with 1mm wall thickness, and it is a good idea to put those in, so as to have replaceable wear surfaces, rather than wearing the aluminium holes. The 10mm hole at the bottom of the post will not require a bush.

Have the 22x22, but want sheet 5mm thick; only have 3mm. Have some 5mm on order; have to wait until it arrives.

A note about the spacing of the two sheets. The required spacing

depends on what shock absorbers are used. I'm not sure, but I

think that motorcycle shock absorbers are 19mm, whereas those on

bicycles and scooters are 24mm.

Just remembered also; the bicycle shock absorbers require 8mm bolts, the motorcycle type require 10mm. At least, for ones that I have looked at.

Here is the SolveSpace file, gzip-compressed:

https://bkhome.org/news/202503/images/t2-susp-swivel-2.slvs.gz

In the above diagram; the 10mm hole at bottom of the post will have a 10mm rod through it. There will need to be grub screws either side, as the swivel-bracket is required to be locked to the rod. Likely I will drill either 4.2mm holes for a m5 bolt, or 5.0mm holes for a m6 bolt (the diagram shows 4.0mm). Probably the smaller. Note, the rod is required to be locked to the swivel-arm as that is part of the tilt control; will probably drill the 4.2mm holes slightly into the rod, before threading, so as to have very positive locking of the rod.

The 5.0mm holes are for m6 bolts, so will need to be drilled-out

to 6mm through the sheets, and tapped in the post.

Oh, and to round off the explanation a bit more; that central

post has a 8mm hole right through, and at the top a m8 bolt can be

slid into it to lock tilting. There will be aluminium sheet above

the swing-arm, with a 8mm hole; slid the bolt through that and

into the post, then no more tilting. Just in case the rider

doesn't want the tilting mechanism, that is how easy it will be to

disable it.

Tags: light

Steering swivel-coupling for new trike project

I have started a new project, to build a full-suspension tilting recumbent tadpole trike from scratch. Here are earlier posts:

- Another look at tilting tadpole trike designs — February 25, 2025

- Planning a recumbent trike built from scratch — February 21, 2025

Cannot guarantee that will finish this project; main interest right now is the technical challenge of implementing the new steering and tilting idea, rather than the end result. Thinking of all those DIYers out there, having detailed plans for parts of a trike will be helpful. This post is one component, the steering swivel-coupling. Measurements and details in this blog post, but there is also intended to be a video on YouTube, showing how it is contructed with a link back to this blog.

The new trike needs a name, so how about "The Meanderer"?

EDIT:

I decided to remove this first contruction post, as it is

a bit premature. I'm still thinking out some details.

Tags: light

Another look at tilting tadpole trike designs

I have started a new project, to build a full-suspension leaning tadpole trike, from scratch. Previous post:

- Planning a recumbent trike built from scratch — February 21, 2025

I have been looking at leaning-trike designs over the last couple of years, and had intended to implement it in the current trike build. But, decided it is too complicated, and ended up with a non-leaning trike. Here is the tilting mechanism that I considered, late in 2023:

- Two-shock design with swinging steering linkage — November 18, 2023

The problem back then, was could not figure out how to connect the tilt mechanism to the steering arms. Have come a long way since then, and now have a design that is simple and looks like it will work. However, taking a bit of a retrospective look, at what others have done and posted on YouTube...

1: Tilting by balance

Most of these are DIY projects. A few guys have built trikes that rely on balance, like you balance on a bicycle. The entire trike, from the rider back to rear wheel, is free to rotate and relies on the rider shifting weight to keep upright. The two front wheels do not rotate, they stay vertical on the ground. In the last couple of blog posts, posted links to "Graham Makes Stuff" YouTube videos; in Part-6, he attempted a leaning mechanism, and went for the balance method. He used a disk brake and caliper, like this:

There is a lever on top that locks the disk, so no tilting. Once underway, the rider releases the lever, then relies on balance, just like a bicycle. However, Graham's experience was that it was very difficult to stop the trike from just falling over.

On a bicycle, the rider is high, making it easy to balance; not so on a recumbent trike. There are a few of these type of designs, including this one, in the "Metal Machine Shop" channel:

https://www.youtube.com/watch?v=NkPyv3-LZmU

...he also experienced balance problems, and has proposed a "MK2" with higher seating. That will help, but is it enough?

2: Tilting hard-linked to the turning arms

What I mean by this, is that the lean is directly linked to how much the rider turns the steering arms. So, turn the steering arms to go left or right in a wide arc, the trike will lean a little bit. Turn to go around a sharp corner, the trike will lean into the corner a lot.

An example of this is the AR3 trike:

https://www.youtube.com/watch?v=t1sUOtY4fYs

Reports from tests are that directly linking leaning to turning

radius is not so good. For example, you might turn the steering to

negotiate a very sharp turn, at very low speed, and the trike will

lean way over into the corner; potentially causing the trike to

topple, especially if the back wheel has luggage above it, causing

a rather high centre of gravity -- that back wheel can drag the

entire trike over.

The AR3 has another problem, that you can see from the photo; despite being tilting, the width has to be wide, as the entire front assembly pivots. This trike actually got to production, but was not a success.

3: Independent turn and tilt control

There have been a few of these type, DIY projects. The one that I am most familiar with, was made by Martin, who lives in Western Australia. That was his "EATSRHPV" trike, about 9 years ago:

"EATSRHPV Tilt mechanism with Steering levers completed"

https://www.youtube.com/watch?v=koADanl4-vo

...He has posted a series of videos showing construction; very complicated, but it does work. The steering arms are swiveled forward and back to turn, or moved left and right to tilt. So, independently controlled.

There are some others posted on YouTube that look like this independent control, though construction details and mechanism close-ups are not shown.

Of these, Number-3 is clearly superior.I have worked out a design for the proposed new trike, that is the same principle as number-3, with the steering arms independently controlling steering and tilting. It is also a very simple design. The plans have already been drawn up on the computer. I keep looking at the plans, wondering if I have missed anything obvious. But, seems OK; full-suspension with correct camber/toe/Ackermann, as well as tilting. Well, we shall see, have parts on order.

EDIT 2025-02-26:

I forgot to mention, there was a Number-2 type that was

manufactured in 2014 and was in production, briefly. It was the

"Wild Wave", made by Stein Trikes. Here is a video:

https://www.youtube.com/watch?v=zFv9jWgSOOc

There isn't much information about it, but

looking at that video, it seems like Number-2, turning and

tilting locked together.

Stein Trikes seems not to have published

reasons why they discontinued it. Google's "Generative AI" does

give reasons, but they are just guesses.

Tags: light

Planning a recumbent trike built from scratch

I posted a few days ago about this proposed new project:

- Staying with SolveSpace for new trike project — February 17, 2025

My current custom trike started out as a standard trike that I modified, with front suspension, solar panel, etc. Great, but having got hands-on experience with that, have learnt so much, and now contemplating a new project incorporating everything learnt.

Why not build the trike entirely from scratch? let the imagination run wild! That might seem very ambitious, but I reckon it is doable with basic handyman tools. There are DIY trike plans on the Internet, and YouTube videos of guys showing how they made their trike, but I want a complete rethink.

In the previous post, I put a link to YouTube video playlist "Graham Makes Stuff", parts 1 to 4. Just about everybody who builds something like this, finds that it doesn't end, they keep thinking of improvements, and they make many changes. Graham is no exception. The year following building the trike, he made a series of modifications, including adding front suspension. See his later videos:

"DIY Trike build part 5. Riding, testing, things I've changed"

https://www.youtube.com/watch?v=Mm20VcANAkw

"DIY no weld trike part 6. More changes, tweaks and improvements"

https://www.youtube.com/watch?v=OhFYDE0yG8M

While I think of it, Ben, the owner of Trisled, an Australian trike manufacturer, the only Australian trike manufacturer, built this for his dad, a one-off:

https://trisled.com.au/solar-mobility-quad/

...very simple mounting of the solar panel. A curved frame and

attached with cable-ties. Something to consider.

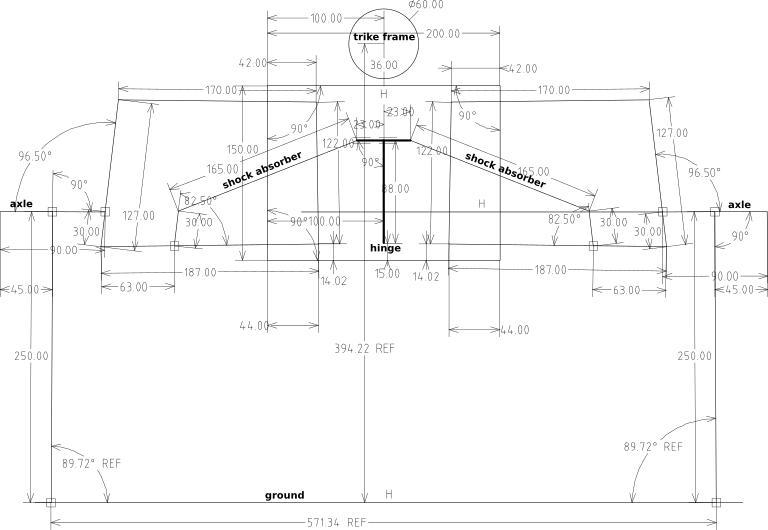

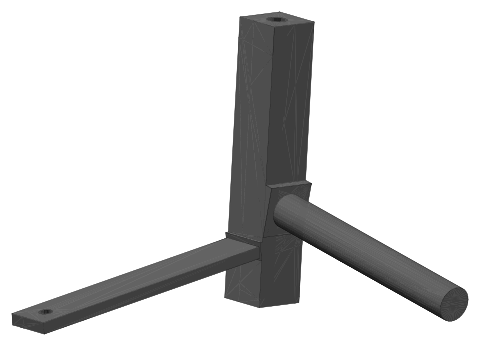

Designing a trike from scratch, no legacy constraints; this is such great fun! Here is a proposed side view:

There are various objectives, one of which is to get the centre-of-gravity very low. The seat is low, also angled so that the pedals will be quite high -- even high enough that there could be a floor-plate to prevent the feet from falling onto the ground.

The yellow colour is the frame, which will be 50x50x3 square aluminium. The reason for it extending high at the back is for attaching the solar-panel frame. Solar-panel, motor, they will be optional; Plan to build the initial trike human-powered only, so as to keep it simple.

The back wheel will have two shock absorbers, each side of the wheel, to keep the length of the trike as small as possible. Though, the forks will be a bit longer than shown in the above diagram, to allow for greater upward deflection of the wheel.

The front wheels have been moved back, a lot more than my current

trike, to avoid the wheels hitting the feet when doing a sharp

turn. I still want the trike to be narrow, at most 730mm, so as to

easily go through doors. The narrow width is another reason why

want to get the centre-of-gravity very low; though, it is not so

urgent due to optional tilting.

The green-filled construction is a round rod, at the right end a swivel to which the steering arms will be attached. Now this is very interesting; the steering arms will allow turning left or right, but also control tilt. The two functions are independent; swivel the steering arms to turn left or right, like any normal recumbent trike, move the steering arms to the side for tilt either way.

There will be a simple mechanism to disable tilt, but if it is enabled, you can go around a corner with as much tilt as you want. This is much better than some other tilting trike designs that have tilt directly linked to the turning.

I'm waiting for an eye operation, in the public system here, as I don't have private health insurance. The public health services here in Australia are very good. There is a date set for the operation, but there is the possibility of being called in earlier. So not going on any trike tour or train adventure for awhile. While here at home for the next couple of months, great opportunity to have fun with this next trike project.

The wheel-knuckle, looking forward to building that. It is

arguably the most difficult part of the project, but I have it

worked out, and can even see how to build it without any welding.

Waiting on some aluminium to arrive.

Tags: light

Staying with SolveSpace for new trike project

Here is the previous blog post:

- Maybe have hit a wall with SolveSpace — February 15, 2025

I opened an issue at github:

"Request: option to do not skew outside face end of extruded

tube"

https://github.com/solvespace/solvespace/issues/1527

I had edited my original request, as it was asking for more than one thing. Reduced it down to one, which looks like it isn't going to happen, but as ruevs posted, there is a workaround.

Member phkahler saw my original request, which included being able to assemble individual components, with each component allowing movement in all directions, that is, 6-degrees of freedom. He informed me that is already supported, with an assembly:

https://solvespace.com/ref.pl#Link

SolveSpace really is great. There is a learning curve of course,

but really it is easy, in retrospect after having learnt how to do

things.

Gotta keep busy doing stuff in my senior years. I have a friend who goes on ocean liner cruises; nah, not for me, would just like to work on projects. What I'm thinking of is contructing a trike from scratch, with all plans published online, and videos.

I've learnt so much, and reckon a complete trike can be built in aluminium with only basic workshop tools. Hand tools, but a drill press also required. A metal bandsaw would be good, for accurate cutting of tube, but could get away with a mitre-box.

A tap-and-die set required. The plan is for the entire trike frame be bolted and pop-riveted, then go to a welding shop afterward and get them to strengthen everything with weld beads here and there.

Starting with the most complicated part to construct, the wheel knuckles. I have figured out a fairly simple way to construct this. Here are the wheel knuckles, firstly left-hand with wheel-axis sticking out to the left:

Here is the right-hand knuckle, with wheel-axis sticking out to the right:

The tube heading toward the observer is for attaching the steering linkage. I chose tube instead of a bar, to make assembly easier. There will just be two holes drilled into the central column, both offset from perpendicular by 10 degrees. A drill-press is required to drill the holes, and the tubes can be held in place by tapping bolts, optionally followed by some welding beads.

The angle bracket is for mounting the disk-brake-caliper.

The central column will have threaded holes tapped at each end,

to which ball-joints or heim-joints can screw. Square tube with

round hole through centre is available; have that on order.

All quite simple, and the proposal is that each step will be

fully documented.

Decided to stay with a 3-wheel design rather than a quad, as in some countries, or States within a country, might have unclear laws whether a quad qualifies as "pedal cycle" that doesn't require registration.

Instead, aiming to achieve a very low centre of gravity for cornering stability. The seat will be much lower than my current trike. Maybe also, aim for simplicity; simple non-electric trike, to which a motor can be added afterward.

I'm reminded of Graham, in his "Graham makes stuff" YouTube channel. He has made a trike with aluminium and some old bicycle parts:

https://www.youtube.com/playlist?list=PLGj2SKPXURTtCF_d9F9Gs4_HbKeDTA-Oj

...no welding.

Some good ideas there, but no suspension. Of course we can pick

issues here and there, but it's a pretty good effort. Example of

one issue is those front wheel-hubs are not really suitable; what

is required is hubs with 15mm or 20mm thru-holes, with sufficient

strength so the axle won't bend due to being supported on one side

only. Those kind of wheel hubs are found in some mountain bikes.

Tags: light

Maybe have hit a wall with SolveSpace

Earlier posts, creating components in SolveSpace:

- Wheel-knuckle designed in SolveSpace — February 15, 2025

- Universal ball joint created in SolveSpace — February 14, 2025

- 3D bottom swing-arm for custom recumbent trike — February 13, 2025

I have previously created 3D models in SolveSpace, that have complete freedom of movement in every direction; however, that was with line diagrams. The ball-joint linked to above, also has freedom of movement in every direction, but that was achieved by creating two lines in the "Sketch --> Anywhere in 3D" mode; then tubes and a sphere were wrapped around the lines.

The wall that I have hit is that extruded models cannot be created in 3D free of being locked to one of the XYZ coordinates. In the "Anywhere in 3D" mode, I created a rectangle; but SolveSpace is unable to make this coplanar.

Coplanar means that the area of the rectangle is flat, not

twisted, which would follow that opposite sides are parallel.

Which is a fundamental requirement before extruding.

The trike model that I am proposing to create, would have many

modules, each in separate files, but each of those modules must be

free of being locked to any coordinate. The trike frame can roll

sideways due to the coil springs compressing, up and down, and

lengthways.

Yes, SolveSpace can create models with linkages, but too restricted for my requirements. It was fun while it lasted. I have been avoiding FreeDraw, but tonight might have a look at it.

EDIT 2025-02-16:

Maybe there is a solution, using SolveSpace. I have put in a

feature request:

https://github.com/solvespace/solvespace/issues/1527

Tags: light

Wheel-knuckle designed in SolveSpace

Continuing learning, constructing various trike parts, this time the wheel-knuckle. Earlier posts:

- Universal ball joint created in SolveSpace — February 14, 2025

- 3D bottom swing-arm for custom recumbent trike — February 13, 2025

- SolveSpace extrude limitation — February 13, 2025

Had a go at modeling the wheel-knuckle, but hit a problem, as

extrusions are at 90 degrees to the work-surface; there is no

mechanism to specify an arbitrary angle. I need extrusions to be

80 degrees, just off being a right-angle.

I came across explanation how it could be done, that I didn't understand. So I did it the only way that I could understand, by creating little wedges. This is the end result:

Intention is it will be all-aluminium, though the wheel-axle could be steel for extra strength. The image is the right-hand-side knuckle. When assembled, the wheel-axle and steering-linkage-arm will both be horizontal, so that the central knuckle shaft will be 10 degrees off-vertical, leaning both backward and inward.

This is an artistic model; in reality those ledges won't be there. The knuckle is the most difficult part of the trike to construct. In my current trike, the knuckle is made mostly of steel, details provided in links here:

https://bkhome.org/nomad/solar-powered-recumbent-trike.html

Actually, have it pretty well sorted out how the knuckle in the

above image can be constructed. The axle will just slide into a

hole right through the central post, then welded in place.

Anyway, lots of fun, but have to stop. SolveSpace file here.

Here is another YouTube playlist:

"SolveSpace - 3D Stuff"

https://www.youtube.com/playlist?list=PLluslK6uBf4sUY_SgOZhBTb_5Vs-XMHZ6

Great that there are so many videos.

EDIT 2025-02-15:

A "Skew" checkbox has been added to extrusions, November 26,

2024:

https://github.com/solvespace/solvespace/commit/f4cfb60ab5c8dbacd5aea3c4cd33b7e72422dcfb

This enables an extrusion to be any angle,

not just perpendicular.

Tags: light