Staying with SolveSpace for new trike project

Here is the previous blog post:

- Maybe have hit a wall with SolveSpace — February 15, 2025

I opened an issue at github:

"Request: option to do not skew outside face end of extruded

tube"

https://github.com/solvespace/solvespace/issues/1527

I had edited my original request, as it was asking for more than one thing. Reduced it down to one, which looks like it isn't going to happen, but as ruevs posted, there is a workaround.

Member phkahler saw my original request, which included being able to assemble individual components, with each component allowing movement in all directions, that is, 6-degrees of freedom. He informed me that is already supported, with an assembly:

https://solvespace.com/ref.pl#Link

SolveSpace really is great. There is a learning curve of course,

but really it is easy, in retrospect after having learnt how to do

things.

Gotta keep busy doing stuff in my senior years. I have a friend who goes on ocean liner cruises; nah, not for me, would just like to work on projects. What I'm thinking of is contructing a trike from scratch, with all plans published online, and videos.

I've learnt so much, and reckon a complete trike can be built in aluminium with only basic workshop tools. Hand tools, but a drill press also required. A metal bandsaw would be good, for accurate cutting of tube, but could get away with a mitre-box.

A tap-and-die set required. The plan is for the entire trike frame be bolted and pop-riveted, then go to a welding shop afterward and get them to strengthen everything with weld beads here and there.

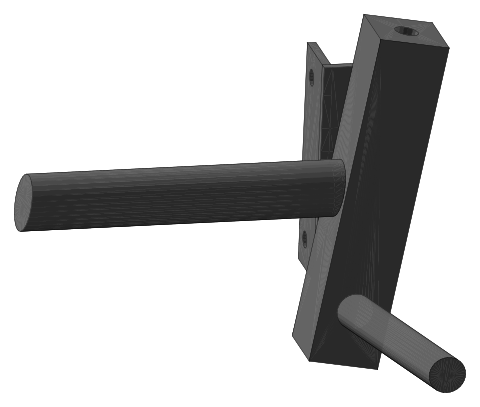

Starting with the most complicated part to construct, the wheel knuckles. I have figured out a fairly simple way to construct this. Here are the wheel knuckles, firstly left-hand with wheel-axis sticking out to the left:

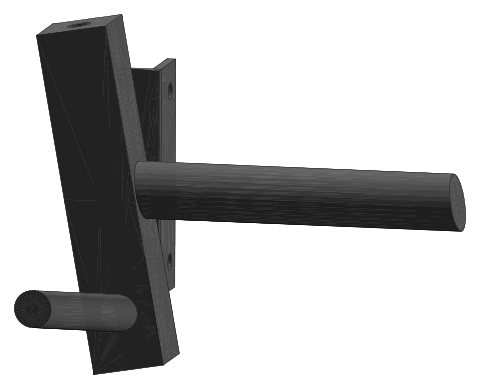

Here is the right-hand knuckle, with wheel-axis sticking out to the right:

The tube heading toward the observer is for attaching the steering linkage. I chose tube instead of a bar, to make assembly easier. There will just be two holes drilled into the central column, both offset from perpendicular by 10 degrees. A drill-press is required to drill the holes, and the tubes can be held in place by tapping bolts, optionally followed by some welding beads.

The angle bracket is for mounting the disk-brake-caliper.

The central column will have threaded holes tapped at each end,

to which ball-joints or heim-joints can screw. Square tube with

round hole through centre is available; have that on order.

All quite simple, and the proposal is that each step will be

fully documented.

Decided to stay with a 3-wheel design rather than a quad, as in some countries, or States within a country, might have unclear laws whether a quad qualifies as "pedal cycle" that doesn't require registration.

Instead, aiming to achieve a very low centre of gravity for cornering stability. The seat will be much lower than my current trike. Maybe also, aim for simplicity; simple non-electric trike, to which a motor can be added afterward.

I'm reminded of Graham, in his "Graham makes stuff" YouTube channel. He has made a trike with aluminium and some old bicycle parts:

https://www.youtube.com/playlist?list=PLGj2SKPXURTtCF_d9F9Gs4_HbKeDTA-Oj

...no welding.

Some good ideas there, but no suspension. Of course we can pick

issues here and there, but it's a pretty good effort. Example of

one issue is those front wheel-hubs are not really suitable; what

is required is hubs with 15mm or 20mm thru-holes, with sufficient

strength so the axle won't bend due to being supported on one side

only. Those kind of wheel hubs are found in some mountain bikes.

Tags: light