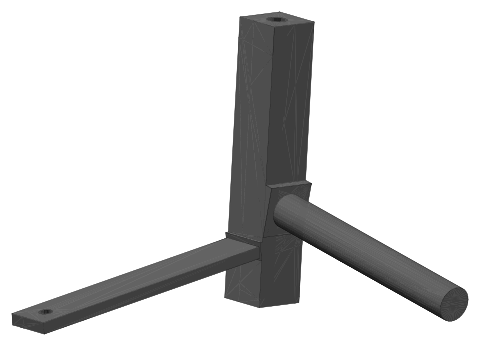

Wheel-knuckle designed in SolveSpace

Continuing learning, constructing various trike parts, this time the wheel-knuckle. Earlier posts:

- Universal ball joint created in SolveSpace — February 14, 2025

- 3D bottom swing-arm for custom recumbent trike — February 13, 2025

- SolveSpace extrude limitation — February 13, 2025

Had a go at modeling the wheel-knuckle, but hit a problem, as

extrusions are at 90 degrees to the work-surface; there is no

mechanism to specify an arbitrary angle. I need extrusions to be

80 degrees, just off being a right-angle.

I came across explanation how it could be done, that I didn't understand. So I did it the only way that I could understand, by creating little wedges. This is the end result:

Intention is it will be all-aluminium, though the wheel-axle could be steel for extra strength. The image is the right-hand-side knuckle. When assembled, the wheel-axle and steering-linkage-arm will both be horizontal, so that the central knuckle shaft will be 10 degrees off-vertical, leaning both backward and inward.

This is an artistic model; in reality those ledges won't be there. The knuckle is the most difficult part of the trike to construct. In my current trike, the knuckle is made mostly of steel, details provided in links here:

https://bkhome.org/nomad/solar-powered-recumbent-trike.html

Actually, have it pretty well sorted out how the knuckle in the

above image can be constructed. The axle will just slide into a

hole right through the central post, then welded in place.

Anyway, lots of fun, but have to stop. SolveSpace file here.

Here is another YouTube playlist:

"SolveSpace - 3D Stuff"

https://www.youtube.com/playlist?list=PLluslK6uBf4sUY_SgOZhBTb_5Vs-XMHZ6

Great that there are so many videos.

EDIT 2025-02-15:

A "Skew" checkbox has been added to extrusions, November 26,

2024:

https://github.com/solvespace/solvespace/commit/f4cfb60ab5c8dbacd5aea3c4cd33b7e72422dcfb

This enables an extrusion to be any angle,

not just perpendicular.

Tags: light