The Mawson Trail

A week ago, I reported about Mark, who rode his velomobile from Perth to Sydney, via Melbourne, about 5,000km, in autumn 2023:

https://bkhome.org/news/202312/velomobile-across-the-continent-twice.html

A velomobile is a recumbent bicycle, trike or quad, inside a shell.

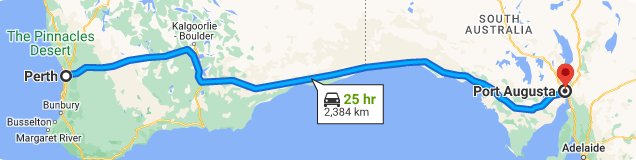

Today I watched a YouTube video from a guy who is riding a mountain bike on the Mawson Trail in South Australia, heading south toward Adelaide. To show where the Mawson Trail is, if I had to get there from Perth, would first have to go to Port Augusta:

...25 hours, driving non-stop at the speed limit! The highway

from Perth is the Great Eastern Highway, and following along the

south coast it is the Eyre Highway.

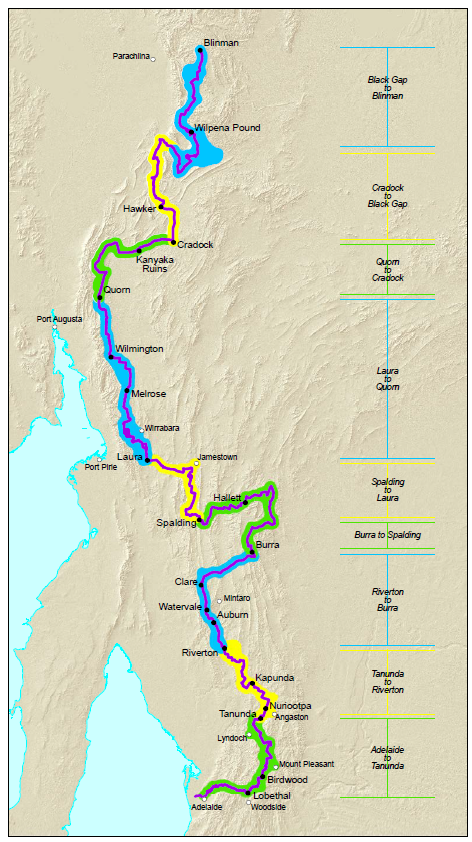

The Mawson Trail runs roughly north from Adelaide, ending at Blinman, a distance of 900km:

This video I watched today, his name is Steve, is episode 3 of his journey south on the Mawson Trail. The video ends at Hallett, and he posted the video only 2 days ago:

"E Bike Touring the Mawson Trail – South Australia - Will The

Torture Never End? Eps 3"

https://www.youtube.com/watch?v=dNkl4lc9quE

About 17 minutes into the video, he met a couple of recumbent trike riders:

...interesting, they have electric motors, as does Steve's

mountain bike. Full suspension is recommended on the Mawson Trail,

but those trikes don't look like they have front suspension; can't

tell about the rear wheel. They will be feeling the bumps! Note,

their faces look dark, as they are wearing insect screens.

Here is a page introducing the Mawson Trail:

https://cycletrailsaustralia.com/2_trails/mawson-trail-sa

That would be a very interesting ride; Perth to Port Augusta, cut across to Quorn, follow the Mawson Trail up to Blinman, then go north-north-west to Alice Springs, right in the centre of Australia. Then take the inland highway west, the Great Central Road, back to Perth:

...now that would be an adventure! Mostly unpaved, and permits

are required to travel through Aboriginal land. The only other way

to return to Perth on entirely paved road, apart from going back

along the south coast, is to go north from Alice Springs, then

follow the coast westward then down the Great Northern Highway.

Tags: nomad

Velomobile across the continent, twice

I stumbled upon this in a YouTube video; a guy named Mark, who rode his velomobile from Perth to Sydney, across the Australian continent, a distance over 5,000km. The video is an episode of the Laid Back Bike Report:

https://www.youtube.com/watch?v=yiJ8q5pvUEU

He did it the first time about 9 years ago. He rode a green velomobile, made in Australia by a company called Trisled. He gave it a name; "Jelly Bean". He has also referred to it as his "mk1".

His velomobile is a tadpole recumbent trike, with a plastic shell

to make it very streamlined.

I posted about a guy who was riding a tadpole trike around the world, including down the Munda Biddi Trail and across Australia:

https://bkhome.org/news/202311/recumbent-trike-on-the-munda-biddi-trail.html

And there was a young couple who rode tadpole recumbent trikes, one of them full-suspension electric solar-powered, 11,000km around Australia, finishing early in 2023:

https://bkhome.org/news/202305/outback-adventure-solar-powered-recumbent-trike.html

When Mark started riding his green velomobile, he became addicted, rode it regularly, then got interested in crossing the continent. He had it shipped to Perth, then rode it to Sydney, about 45 days. He bought it secondhand, and after owning it for 9 years it was getting worn out, mostly the frame was rusting. So he bought another from Trisled, his orange "Jaffa", and then had to do the entire continent crossing again. Same thing, Perth to Sydney. Here is a photo:

...he said it took 20 minutes in the morning to pack everything into the Jaffa and be ready to go.

The second trip was early in 2023 and Mark has posted about it here:

http://rvvelonaut.blogspot.com/

He also has a YouTube channel; most videos are of the first trip:

https://www.youtube.com/@rotovelo_naut/videos

These velomobiles are legal on Australian roads. However, on these cross-continent trips he got stopped by the police about 20 times. In some cases, people had phoned the police, reporting that there is an "illegal unregistered vehicle" on the road.

He didn't bother with visibility flags, which maybe would have been a good idea. His attitude was that his bright-orange velomobile is highly visible, in spite of being very low. But I think that it would allay people's fears if they see it has high flags waving. This question about flags is discussed here:

https://www.bicycles.net.au/forums/viewtopic.php?t=46056&start=1700

...as someone commented, flags are good for "Keeping away people who insist on telling you that you need a flag".

What would be the downsides of being encased in a plastic shell? First thing that comes to mind, is the temperature in the Australian Outback in summer can reach 45 degrees Celsius, even higher. Maybe if the shell had a flap in the front, that could be opened to allow air to flow through.

Regarding legality, Mark's Jaffa is about a metre wide, which is

illegal in Western Australia. In theory, anyway, as the police

have ignored that rule, given that all recumbent trikes and many

mobility vehicles are wider than the 660mm limit. But, in

mid-2022, the limit in WA was increased to 800mm, and it is now

more likely that the police will pay attention to this limit. Most

trikes are over 800mm, so still technically

illegal.

Tags: nomad

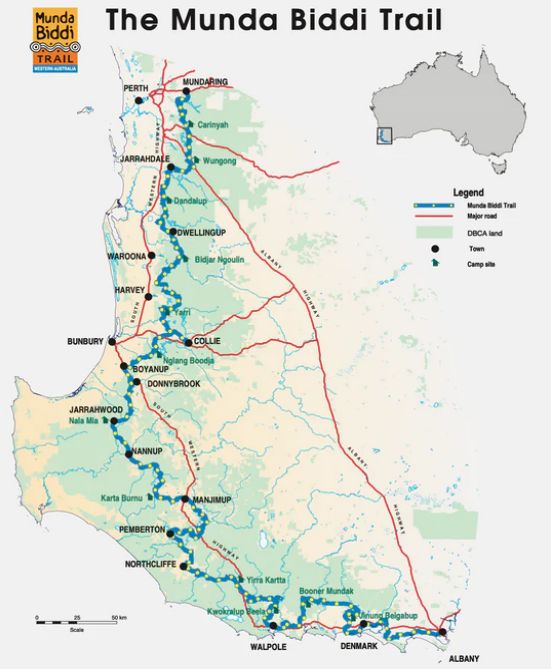

Recumbent trike on the Munda Biddi Trail

The Munda Biddi Trail is for bicycles. It very roughly follows parallel to the Bibbulmun Track, which is for walkers. The Munda Biddi Trail is 1067km, extending from Mundaring (just outside Perth) down to Albany on the Western Australian South Coast:

I aways thought that it would be unsuitable for a recumbent trike, as it is really designed for mountain bikes. The trail varies from fire-roads, to narrow rocky tracks, to sand tracks, and in places very steep. Yes, even the official website says recumbents are not suitable:

https://mundabiddi.org.au/blogs/faqs/what-sort-of-bike-will-i-need-to-ride-the-munda-biddi-trail

However, I was reading this page, and there was mention that someone did the entire length on a tadpole recumbent trike:

http://thelongwaysbetter.blogspot.com/p/munda-biddi-trail-wa.html

I followed the link, to "Every Which Way But Lost" YouTube channel. I don't know his name. He retired from a military career, it looks like about four years ago, and is now touring the world on his Azub full-suspension trike. Here is the link:

https://www.youtube.com/watch?v=vgCFSqRFSmg

The video is 40 minutes; I watched all of it. Very interesting; he did a lot of pushing...

...knobbly fat tyres would have helped. But then, his trike has to be multi-purpose, and knobbly fat tyres are not the best on roads.

After reaching Albany, he went across the Nullarbor Plain to the East Coast of Australia, which is also a very interesting video. Here are all his videos:

https://www.youtube.com/@EveryWhichWayButLost/videos

I was curious how he managed to fly with his trike. He showed a video how he packed it when flying from Bali to Australia:

https://www.youtube.com/watch?v=pECpUi_pVx4

...I wonder what that cost?

Tags: nomad

Problem riding a recumbent trike uphill

Chatting with people about recumbent trikes, I have been asked this question a few times; "what is it like going up a hill?"

Difficult, because, unlike a bicycle, where you can stand up and put your weight on the pedals, with a recumbent bike/trike, you are lying down and relying entirely on leg muscles. Furthermore, they are leg muscles that you don't use much. It doesn't take very long when struggling up a hill, before "everything hurts".

"Laid Back Mickey" posted a video about this, and why you do need an electric motor:

https://www.youtube.com/watch?v=h-yAnQdMb-k

...either a motor, or extra-low gears, or get out and

push!

Tags: nomad

More recumbent solar-powered trikes

I posted about a young couple riding 11,000km around Australia on recumbent trikes, one of them solar powered. They were Azub trikes, and the solar panels were added by the young couple. The link also has information about a ready-made solar-powered recumbent trike, the Motrike/Trikexplor 320E-Solar:

https://bkhome.org/news/202305/outback-adventure-solar-powered-recumbent-trike.html

Since then, I have found other DIY solar power conversions. There was a guy here in Australia who did it in 2014. There was a post to an Australian bike forum, don't know the outcome. Um, might have the link in my browser history; yes, here:

https://www.bikeforums.net/touring/934933-set-solar-trike-tour-us-australia.html

He also posted at the Azub blog:

https://azub.eu/set-on-a-tour-across-usa-and-australia/

About two years ago, I guy in the USA did a DIY solar conversion of a Catrike Road trike and posted videos. Here is one of them:

https://www.youtube.com/watch?v=Jx9LjzPxL7M

And one of his posts about a year ago:

https://www.youtube.com/watch?v=9FAm5R5yNcI

There are more that I stumbled upon. For example, this guy in the USA posted how he constructed the solar panels frame:

https://www.youtube.com/watch?v=Ji3v9UKhvt8&t=68s

...I see in his testing, he connected the solar panels direct to

the battery, no MPPT (Maximum Power Point Tracking) controller, so

his test result is far from optimum.

Tags: nomad

How to buy the Motrike 320E-Solar trike

Post deleted.

Tags: nomad

How to be safe on a recumbent trike

Continuing a series of posts about recumbent trikes. When you see "bent riders" cycling along, the thought that does come to mind is what will happen if a foot falls off the pedal and hits the ground ...ouch!

Ha ha, recumbent riders refer to themselves as bent riders.

They also refer to the foot falling off onto the road as "leg suck". This video lists 5 safety tips, including how to avoid leg suck:

https://www.youtube.com/watch?v=Tnad_ibvwY8

...the other four safety issues can be managed; I think the main concern, for me anyway, is leg suck. It looks like mountain-bike shoes are the way to go. These lock onto the pedal, as this video shows:

https://www.youtube.com/watch?v=0HdO5b2Pu1c

These shoes are readily available. For example, here in Australia, the "99 Bikes" retail chain has lots of them, as well as cleats and pedals. Here is a photo of one of the shoes:

This cleat system also is a huge plus factor for long distance

riding; as the feet are locked onto the pedals, no energy needs to

be expended to keep them there.

Tags: nomad