DIY solar e-bike guides and kit

Fascinating what can be discovered online, when one persists with searching.

I have posted about a solar-powered electric recumbent trike available for purchase:

https://bkhome.org/news/202305/outback-adventure-solar-powered-recumbent-trike.html

Yesterday, posted about recumbent rider groups in Australia:

https://bkhome.org/news/202305/what-kind-of-people-ride-recumbent-trikes.html

One of the members of the Adelaide group has built a solar panel on his recumbent:

...interesting, it is a quad bike. My understanding is that in WA and

most States, a quad is considered not to be a bicycle and is required

to be registered. Maybe the law in South Australia is different. Or, he

has been able to classify it as a disabled mobility vehicle.

Today, discovered a website that offers a complete kit:

https://ebikes.ca/learn/solar.html

I have posted this link here partly for my own future reference, as

the "learn" section on their website is

fantastic.

Tags: nomad

Car secure window vent

Every year, in Spring-Summer-Autumn, I head off on camping trips, some of which are documented here:

https://bkhome.org/light/index.html

https://bkhome.org/nomad/index.html

The camping equipment includes a Waeco 12V fridge and a lithium "powerbox". Construction of the powerbox is described here:

https://bkhome.org/nomad/barrys-lithium-powerbox.html

I leave the powerbox and fridge in the car, the powerbox sits on the passenger-side foot-well and the fridge on the passenger seat. The car window has to be left slightly ajar for ventilation and cables -- which is a problem. The open window has these issues:

- Mosquitoes get inside the car.

- Rain comes in.

- Not secure.

Two cables, one to the solar panel, the other a 12V power supply into the tent. Inside the tent, I run laptop, lights and fan off the 12V.

There is a chair and table inside the tent, but I often like to sit in the car, and that's when I discover the mosquitoes.

I don't expect much rain in the summer months, but it can happen, so that is another problem.

Go for lots of walks, leaving the car unattended, and although they are really nice people I meet at campsites, there may be a rare someone who is an opportunistic thief. The window opening only needs to be open a little bit, so fairly secure.

I thought, why not, put something together out of the aluminium sheet and extrusions in my shed. OK, this is an experiment. Here it is:

The fibreglass mosquito screening is glued on with silicone sealant. Affixed to the window:

It isn't pretty, but should do the job. Will find out how well, very soon.

I constructed it without much forward planning, learnt a few things along the way. If I did it again, would make some changes:

- Used 0.5mm thick sheet, as that was all I had. About 1mm thick would be better.

- I riveted angle extrusion over the holes, for a modicum of rain protection, but I think a continuous strip of angle the entire length, with notches cut so that it can be bent to follow the curve, would offer better rain protection and rigidity.

- Sliding it over the window would be easier if the overlap was

graduated. The overlap is 10mm, but next time I would cut the

aluminium sheet to say 10mm on the right-side (above photo),

gradually increasing to say 15mm overlap. This would make it

easier to slide on.

Sometime in the future, if this one turns out well on a camping trip, will probably construct another for the driver's side window, so that there is thru-ventilation. I will endeavour to park the car in the shade; however, on hot summer days the car interior will warm up -- which is not so good for the fridge.

Having said that, the Waeco fridge is incredibly efficient and

can easily handle high ambient temperatures.

Keen to go camping!

EDIT 20221006:

Was discussing the window vent with Mark C, and another reason

came up why it may be very useful. Sometimes when driving to the

South Coast of Western Australia from Perth, I don't get all the

way on the same day. It depends which route and which

destination, but many rural towns offer free RV overnight, and I

have used those, sleeping in the car.

Stayed a couple of times at the free overnight site at the little town of Ravensthorpe:

https://www.aircamp.com.au/campsite/ravensthorpe-rest-area

...a nice place. There are toilets over the road. The town centre is just a short stroll away.

Anyway, this is another scenario where the

secure vent is good to have, Keeps out the mozzies and provides

ventilation.

Tags: nomad

Camping at Cozy Corner

I have been on a camping adventure on the South Coast of Western Australia. Stayed at Parry Beach Campsite and Cozy Corner East Campground.

Parry Beach costs AU$20 minimum per night, except the host only charged me $10, as I had a small site. Quite crowded, lots of families, kids everywhere, this is peak summer, school holidays.

Initial impression; lots of mosquitoes.

http://www.findacamp.com.au/camp-site.php?camp=1760

Next, I went to Cozy Corner East Campground. Like Parry Beach, no booking, just turn up, but this one is free. Maximum stay 7 days.

https://www.aussiecaravanninglifestyle.com/cosy-corner-east-free-camp-wa/

Here is a video:

https://www.youtube.com/watch?v=A8zFxCxN0cs

My impressions:

Nice place, you can't beat FREE. There is one downside to the tent-only area, it is just over a sand dune from the ocean, so there is the continual sound of the waves crashing. OK, but a bit too loud if you like quiet to get to sleep.

I did not experience any mosquitos, but there are March Flies -- these bite.

https://www.healthywa.wa.gov.au/Articles/J_M/March-flies

Although it is crowded, the 7-day limit meant a continuous turnover. In the tent-only area, there was nearly always one site available. I observed some people just stayed one night, so if you arrive in the morning there is a good chance of finding a free spot.

Ditto for the caravan camping area. I observed some vehicles at the entrance early in the morning, waiting for people to leave. The Camp Host can help out here, as they have a record of everyone staying, and check with them upon arrive to find out if any spot is scheduled to be vacated.

And then there are those who take off before the allotted 7 days are up. So yeah, even if you have a large RV or caravan, just arrive early in the morning and you have a very good chance of finding a vacant spot. This is peak holiday season, so the situation should be even better off-peak.

No phone signal in my tent, but a short walk to the beach and got

a weak signal. Also, there is a path up a sand dune with weak

signal at the top. I am with Vodafone.

Tags: nomad

Stealth camping

Here in Australia, there is a growing trend of people in

campervans "free camping", illegally or otherwise. Many shires on the

East Coast are getting quite aggressive about this, imposing large

fines. But it still goes on, and there are websites with guidelines on

how and where to park. Like, for example, make your van look like a

tradesman's van rather than a campervan.

But stealth camping can also apply to those just on their feet. Homeless people of course.

Many years ago, while travelling by car, bus or train in urban areas,

I had the habit of spotting places where I thought someone could camp

overnight without being seen. Don't do that anymore, but I was surprised

to read that others also have that habit:

https://bushwalk.com/forum/viewtopic.php?p=173814#p173814

There are some YouTube videos with guidelines to stealth camping on

the foot. I recall, a couple of them advised that you need to look like

you are just out for a day walk. A lumbar pack or small shoulder pack,

but not a big backpack with tent poles strapped to it!

There are a lot of bush trails east of Perth without designated

overnight camping, for example the track from Mundaring to Northam. I am

sure that many people just camp discretely, leaving no trace.

There is also an attraction to stealth camping -- security. On a

trail, if you find a spot off the trail, you can easily select a place

where no one is likely to see you. As opposed to staying at a designated

overnight shelter, where everyone on the track will see you.

If you search for "stealth camping" at YouTube, you will find heaps of hits. Here are a couple from Steve:

https://www.youtube.com/watch?v=Qhf88k9MRZM

https://www.youtube.com/watch?v=54H0aYgS6wo

Tags: nomad

Day 55 end of Perth to Albany walk

I posted about Caroline walking the Bibbulmun Track, from Kalamunda in Perth to Albany on the south coast.

After completing the walk, she and her cameraman Steve have been

putting the videos together, and finally, today, uploaded episode 17,

day 55, when they reach Albany.

Here is my blog post at start of journey:

https://bkhome.org/news/202103/young-ladies-walking-solo-on-the-bibbulmun-track.html

She was solo for a couple of days near the beginning, as Steve had to

drop out for medical reasons. Then again he had to drop out the last

couple of days. He rejoined for about the final 10km walk into Albany,

and if you watch that final video, you will see the camera work changes

with Steve's unannounced presence:

https://www.youtube.com/watch?v=Gh3gsy57qWI

Fantastic to watch. Don't know if I will ever do the entire 1,000km, but certainly love doing bits of it.

Tags: nomad

Young ladies walking solo on the Bibbulmun Track

These are nice presentations. Walking solo on a multi-day hike is

as much a mental journey as a physical one, and it is interesting how

each person adapts to the walk.

Caroline starts with a partner to do the filming, but soon finds

herself solo. This is interesting, as she is a person who likes company,

and suddenly finding herself alone was a challenge mentally. Here is

the first part of the journey:

https://www.youtube.com/watch?v=kwT6XQJ9N8A

...Caroline walked the entire 1,000km, and has posted videos of the entire journey.

Dori is someone who is at home with herself, who prefers solo hiking.

It does require some mental adjustment though, especially the feeling

of being vulnerable. She posted a video about this:

https://www.youtube.com/watch?v=R7SQD3jnQgQ

And here is the first post on her journey heading southward on the Bibbulmun Track:

https://www.youtube.com/watch?v=h_05N58qoWE

She only posted that on March 14, 2021, and has posted the first and second videos so far.

People walk solo for all kinds of reasons. The two young lasses

above, liked to meet people along the way. Some are loners, just like to

be to themselves.

Just remembered, I met a lass who seems to be a professional solo

hiker, trail-name "Drop Bear", at Hewitt's Hill Campsite, in 2016. If I

recall rightly, she was just starting on the journey, heading south.

Found a page about her:

https://thetrek.co/arizona-rocks/20180412_123802/

Yes, she walked end-to-end, and is in the "End-to-Enders Gallery":

https://www.bibbulmuntrack.org.au/news/end-to-enders-gallery/e2e/53106#

Interesting choice of lifestyle.

Tags: nomad

A hike around Lake Walyungup

The State of Western Australia is in a fortunate situation, as it

is coronavirus-free. The only cases are those of returning

international travellers, and they get isolated for two weeks. As far as

the rest of Australia is concerned, unfortunately, Victoria has let the

country down, with many new cases every day -- which was caused by

incompetent isolation of returning international travellers -- it was

mostly the security guards, apparently, who were responsible for

spreading the virus from the isolation-hotels to the wider community.

Anyway, here in WA, we have had competent handling of the crisis, and

we are just about back to normal. I am getting around on public

transport and going to favourite restaurants. Today, went for a hike,

before some lunch and shopping...

While considering where to hike in the Rockingham-Warnbro area of WA, I stumbled across "metrotrekker" Marc's website:

https://www.metrotrekker.com/search?country=All_Countries&city=All_Cities

Marc hikes in metropolitan, or outer-metropolitan, areas, accessable

at each terminus by public transport. He has hiked in Europe, Japan,

Singapore and Australia. I wanted to walk around Lake Walyungup, and

found that he has done that:

https://www.metrotrekker.com/australia-perth-hiking-a-walk-on-lake-walyungup

I drove there, but if you come by public transport from Perth, take

the Mandurah Line and get off at Warnbro Station. This is about 37

minutes train journey. Walk East from the station, along Safety Bay

Road, not far, and you will see a parking spot on the right, and a very

small one on the left. On the south side, there is an entry gate to the

lake:

...the time is about 10.00am, on Sunday, July 5, 2020 (mid-winter),

and there were several cars parked, so other hikers were encountered.

What's so special about this lake? Nothing in particular. Perth is

located on a coastal sandplain, so that is the kind of terrain, sand and

limestone. South of Perth City, the suburbs have sprawled right down to

Mandurah and beyond, and there is a metro train line that terminates at

Mandurah, running through Rockingham and Warnbro.

There is a military base on Garden Island, close to the coast just

north of Rockingham, and they used Lake Walyungup for target practise,

and I saw the warning:

No longer of course! As to footpaths, there are some, but it is mostly a huge expanse of flat sand and limestone:

...there isn't much water, and the ground is firm, as it is limestone sprinkled with sand.

Google map shows lots of water, but it is in actuality much less. I

walked south, on the west side of the lake, then cut across east, and

walked back on the east side of the lake. It seems that there are two

bodies of water, so walking south from the entrance, one can walk east

across the land that separates the two bodies.

I then walked north along the east side of the lake, and took a photo to prove that there is still some water here:

I ambled about a bit, and the walk took about 2 hours. If someone

walked closer to the water, the walk around it and back to the car park,

would be about 1.5 hours, maybe less.

A pleasant walk, no spectacular scenic features, but of interest to observe the type of terrain and plants.

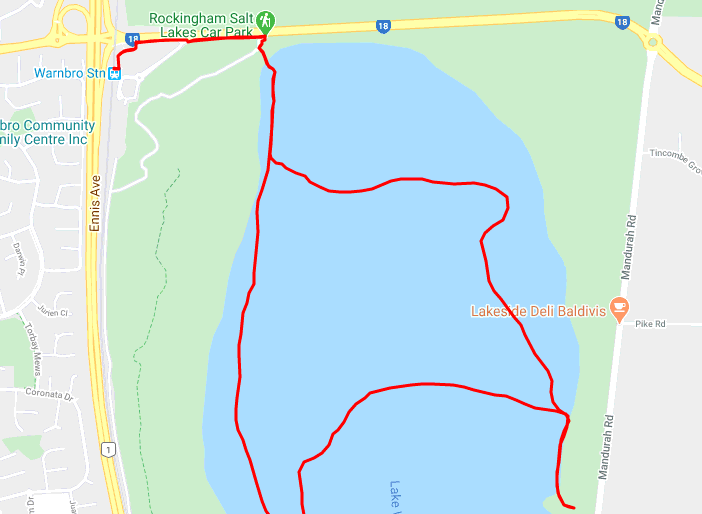

Stealing Marc's map of where he walked:

...in my case, I walked down the west side of the lake, until I saw

that Lakeside Deli directly east, then walked across. I could not see

any access to the deli, nothing easy anyway. Instead, I went back to my

car and drove to the nearby Waikiki Shopping Centre and bought a Jesters

pie and chips for lunch -- hey, there is a lot to be said in favour of

urban trekking!

Tags: nomad

Giandel 300W Pure Sine Wave inverter mini-review

I have owned a modified-sinewave 150W inverter for a very long time,

probably about 15 years, and it has been taken on camping trips.

However, has seen very little use, as it does not have enough grunt.

On a recent trip, I tried to use it to drive my LCD/LED TV (an old

55cm 1080p TV that I usually use as a monitor) and (not at the same time) my

"big" laptop, without success. The TV for example, the power-LED just

kept flickering on and off and the screen stayed dark -- it must be the

startup current is too high. So, time for a higher-capacity inverter,

and also one with "pure" sinewave output, more suited to driving

electronic equipment.

Actually, I do have a DC-DC converter for my "big" laptop, 12V in,

18V out, that plugs into the cigarette lighter socket, and that works

well. Also, the TV is capable of running directly off 12V -- it would be

just a matter of making up a suitable cable.

So, there is no immediate need for an inverter, but I got the itch...

After some research, I settled on a 300W inverter. That suits the

maximum current that my powerbox is designed to handle, and is enough

for TV and laptop and something else running together. Or an electric

drill.

Prices vary from AU$78 to over $350 -- for what seems like the same thing. At the top-end, there is this Redarc 350W inverter:

https://www.mygenerator.com.au/redarc-350w-12v-pure-sine-wave-inverter.html

...I studied the specs in a PDF, and the no-load input current is

stated to be <0.9A. If the input voltage is 13V, then it is consuming

<11.7 watts. Efficiency is stated as 89%. Redarc is an Australian

company with local manufacturing, which these days is a rarity. It does

mean more expensive than Chinese products, however the quality is

top-notch.

https://www.redarc.com.au/australianmade

Fast forward to what I ended up purchasing, this Giandel 350W Pure Sine Wave inverter, for just AU$78.96, including delivery:

Note, this does look like a generic Chinese product. I have seen other brands on eBay and YouTube that look the same.

Before ordering, I contacted the vendor and they confirmed that they

ship by Australia Post -- some eBay vendors use Fastway Couriers (now

renamed to Aramex), but after they lost my parcel earlier this year, and

reading about them on productreview.com.au, I vowed never to buy from

any eBay vendor that uses them.

So, the Giandel inverter came by Australia Post, and it came fast, very pleased.

Here it is, setup, running off the lithium powerbox, powering my big laptop:

Now here is something very interesting: the online specifications

state that the no-load input current is 1 ampere. However, I measured

it: 13.3V input, at 0.47A. Only 0.47 amperes!

Most of the other 300W cheapies claim around 0.9A standby current.

Except I did find one that claims <0.4A, the Elinz INTPW300:

The Elinz inverter claims over 90% efficiency, and something

important, Australian "C-Tick" EMC compliance. I didn't give that much

thought at time, but the importance became obvious later, when I tested

the Giandel.

There is no C-Tick shown anywhere on the Giandel or the

documentation, nor can I find it on their website, giandel.com.au -- except that it does state "Australian standard design". Which

means that it is illegal to use in Australia, I think. It is probably

one of those legal-grey areas.

Anyway, the importance of EMC became apparent to me when I powered up

the laptop, and the USB mouse was very erratic. It would freeze

momentarily, work a bit, freeze again.

I did some searching with google, and found that this interference from inverters is

common with laptop touchpads, but I eventually found someone who had it

happening with their USB mouse.

Look at the above photo, where the mouse cable is draped!

Simple solution, moved the cable further away, and less interference.

At about 2 feet away, no interference. This is RF, high frequency radio

waves.

There is an earth terminal on the back of the inverter, which might

help if connected. If I had an "earth" to connect it to. What about when

in a tent, could "earth" be a steel peg in the ground?

Anyway, the solution is just to keep the inverter away from sensitive

electronic equipment. Probably in tent, have it on the floor.

The unit itself looks well made. Very heavy cast heatsink chassis, finned aluminium.

One very good thing -- the fan is intelligent, only comes on when the chassis reaches 40degC. So, runs silent, much appreciated.

I did consider buying the Elinz inverter. Their eBay page states that they use Australia Post:

But when I contacted them, they said that they use both Australia

Post and Fastway Couriers, and a couple others. Although I was enquiring

about the inverter, they did not specifically state which of those

carriers would be used, so their loss, I went elsewhere.

Regarding cabling, the Giandel unit came with two sets of cables, one

with cigarette-lighter plug, the other with crocodile clips.

The cigarette-lighter socket will be fused, maybe 10A or 15A, hence

the other cable set is required to obtain the full power that the

inverter is capable of. My powerbox has an Anderson plug output, so I

will use that to run the inverter -- the Anderson plug is rated up to

50A, but of course need to use heavy cable also. Anyway, my powerbox has

a 30A circuit breaker, limiting power output to around 13x30, which is

390W, a good match for the inverter. Though of course the inverter is specified to handle surges up to 600W.

I loaded the Giandel inverter a bit more: ran the desktop PC playing a video, monitor (my LED TV), a pedestal fan, and a pedestal lamp. All up, was getting 12.8V at 12.5A, which is 159W. Could hardly feel any warmth on that massive heatsink.

Tags: nomad