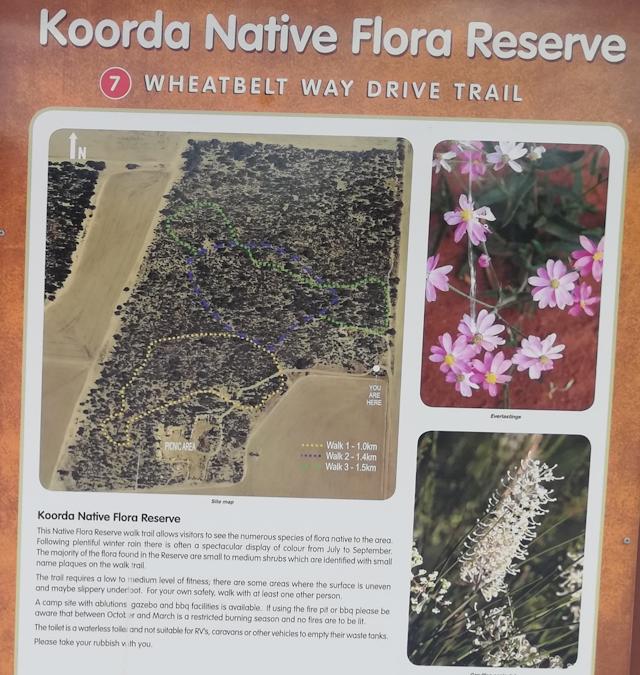

Koorda Native Flora Reserve mini-review

Yay, we are allowed to drive in the Wheatbelt Region of WA! I

went for a trip into the Wheatbelt and as it was too far for a

comfortable one-day trip, looked for somewhere to park overnight. I used

Google, typed in "campsites near Koorda" and got a few hits, including

the Koorda Native Flora Reserve.

Koorda is a small town, about two hours drive from Perth:

https://en.wikipedia.org/wiki/Koorda,_Western_Australia

Google Maps also recognised the reserve and was able to direct me

there. It is about 14km from Koorda. Had a Telstra signal all the way

and also at the site. There is a sign at the entrance:

A narrow track to get in, but a big open area to turn around at the

"picnic area" if you have a caravan. Nice facilities, a covered table:

Also, there are a couple of fire pits and a toilet. The toilet is on

the horizon in the above photo, and needs special mention, as it is very

clean and well maintained:

...there is even soap on the basin!

A big plus point is that it is free. But I do like to give something back, and buy petrol and food in the local town.

Any negatives? Well, yes, the flies. These are annoying little

critters, that try and get into the eyes. These "bush flies" are

prevalent throughout the northern Wheatbelt and further north and

inland. Just have to put up with them. As the evening gets cooler, they

reduce. There is really only 2-3 months from mid-winter when they are

very reduced during the day.

Anyway, apart from that pet peeve, it is a nice little spot, well worth an overnight stay if you are going that way. More links:

https://www.aircamp.com.au/campsite/koorda-native-flora-reserve

https://www.wheatbeltway.com.au/towns/?act=Koorda

Tags: nomad

Ganga Mill Campground mini-review

Here in Western Australia, we have restrictions where we can

drive. As I live in Perth, I am only allowed to go camping in the

Perth-Peel Regions. Though, from Monday 18th May, this will be eased and

driving will be allowed to the Wheatbelt, South West and Great Southern

Regions. That is good, but most of the grey nomads would prefer to be

able to drive north, toward warmer climate.

I checked out what DPAW campgrounds are in the Perth-Peel Regions,

and also don't require pre-booking. Not much choice, in fact, no choice,

only Nanga Mill and Nanga Townsite campgrounds are

first-come-first-served, no booking. So, decided to get away for a

couple of days.

If you live in Perth and just want a quick get-away for the weekend,

it is a good choice, only about 1 hour and 30 minutes drive. You drive

south from Perth, on the South Western Highway, through Byford, then

before Pinjarra there is a turn-off to the left, to Dwellingup. Arrive

Dwellingup, turn left at main street t-junction, go out of town, and

Nanga Road is on the right.

Here is the DPAW page:

https://parks.dpaw.wa.gov.au/site/nanga-mill

Concession price is AU$8 one-time entry fee per car, and AU$7 per night, per person.

I have to admit, these days I prefer coastal camping, just find the

ocean, beaches, etc., so much more interesting. But, thick bushland,

tall trees, do have some attraction.

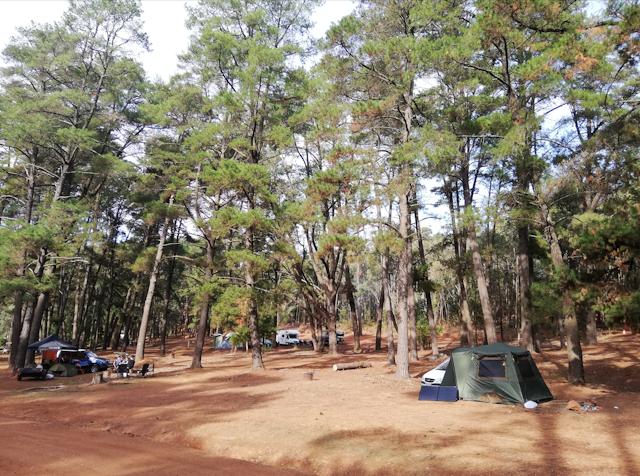

Tall trees, yes, nestled in a valley beside a stream -- very nice,

but a problem for my solar panel. I chose the sunniest spot, and got sun

from about 9.00am to 2.30pm -- either side of those times the sun was

partly obscured by trees. Winter here, so the sunshine hours will be

more in the other three seasons.

This is my camping spot, I am on the right:

...doesn't look like many people camping there, but there were, lots

of people, spread along the stream bank. Most of them were in more

thickly-treed spots then mine.

It was interesting to observe the type of people there. More of the

city get-away-for-a-few-days crowd, than holidayers and grey nomads.

Consequently, some of the groups were "living it up" a bit more than I

am accustomed to.

The group next to me, on left in above photo, had a radio running

from arrival until late at night. On the other side, a fellow played

"bongo drums".

The campsite does not have a camp kitchen, but does have open-air gas

barbecues and fire pits. Many groups availed themselves of the latter,

and there was a pall of smoke thoughout the campsite in the evening. I

don't mind smoke though. Here is one of the barbecues and one of the

bigger firepits:

...the gas is free.

The campsite runs along a stream, which was no more than about 12 inches deep at the deepest, so paddling only:

I didn't see them, but apparently some of the nearby campsites have places where you can swim.

So, what is there to do, apart from paddling in the stream? There are walking trails, various lengths, up to an 18km loop.

So, thumbs-up or thumbs-down? Personally, I would have preferred a

covered kitchen area, and gas-ring stove would have been nice. I spotted

one tap, with non-potable water. There are toilets, the deep-drop kind,

and they were clean and didn't smell.

You have to bring your own wood, and bags are available in Dwellingup

for $10. I have been to DPAW campsites that have wood available for

free.

No phone signal, though there is a notice that Telstra intends to put

a tower there. Radio reception on AM band had a lot of background hiss

and only one station, 558KHz, was listenable. Nothing on FM.

Yeah, overall OK. Depends what you want. A weekend get-away with your

friends, then ticks the boxes. As a stop-over as you do the "big

lap" around Australia, ticks the boxes also. After a few days, most

people would be bored and would want to move on, I reckon -- but then,

everyone is different, and some might like an extended stay, just going

for long walks. Here is some feedback at TripAdvisor:

...some of the other campsites, that require pre-booking, within Lane Pool Reserve look very interesting.

Tags: nomad

Coulometer error creep

I posted about installation and calibration of the coulometer, that displays battery state-of-charge (SoC):

https://bkhome.org/news/202004/installation-of-the-coulometer-lcd-display.html

I used the Amptron 15A LifePO4 mains-input battery charger to charge

the battery to 100%, then set the coulometer to 100% and capacity 50AH.

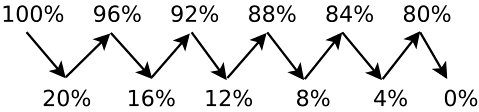

There is however, a problem: a battery charge/discharge cycle is not

100% efficient, there is some loss as heat. The battery may be capable

of supplying 50AH, however, it will require more than 50AH to charge it

fully from empty.

Lead-acid technology battery are very inefficient, only about 70-80%

efficient in the discharge/recharge cycle. LiFePO4 batteries are much

more efficient, 90-92% round trip, see this document:

https://www.victronenergy.com/upload/documents/Datasheet-BMS-12-200-EN.pdf

The problem is that the heat loss is going to mean the coulometer

will read incorrectly, becoming more incorrect with each

discharge/recharge cycle. This is what will happen if we start with a coulometer

reading of 100%, discharge to a reading of 20% SoC, then charge back up

to a reading of 100%, then down to a reading of 20%, and so on:

...this is showing the actual battery capacity (the values

given are for illustration only). After some charge and discharge cycles,

when the coulometer drops to reading 20%, the battery will actually

have reached 0%.

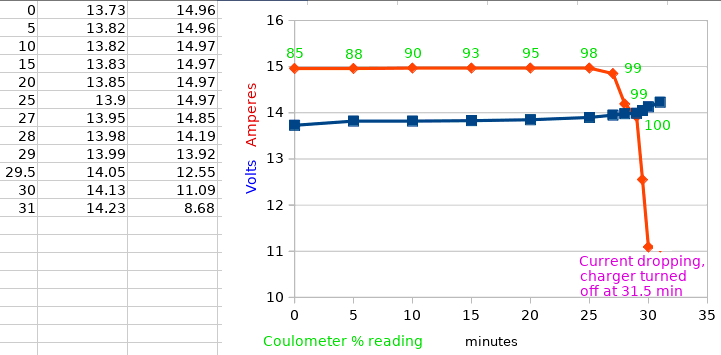

This is bad news, however, the coulometer will self-correct every

time the battery is charged to full. For example, I plugged in the

Amptron mains-input LiFePO4 12V 15A charger, and plotted voltage,

current and state-of-charge (latter as read by the coulometer):

The coulometer has reached a reading

of 100% before the mains charger has finished charging. As you can see

above, the coulometer is reading 100% at 29 minutes, and the charger

keeps going and turned itself off at about 31.5 minutes.

Note, after about a minute, the charger turned back on momentarily,

then did so again after about another minute. I didn't catch the

voltage/current readings, it was a very short duration.

Reaching 100% reading on the coulometer before the charging completes

is a correction mechanism, however, a problem is that this

self-correction is only going to happen if the battery is charged to

full, or nearly full.

We really need another mechanism for the coulometer to self-correct. I

don't see how we can use the charging voltage, however, the coulometer

could be set to read 0% if the battery voltage drops below a certain

value. This web page is a good read, and has some information on

discharge voltage:

https://www.solacity.com/how-to-keep-lifepo4-lithium-ion-batteries-happy/

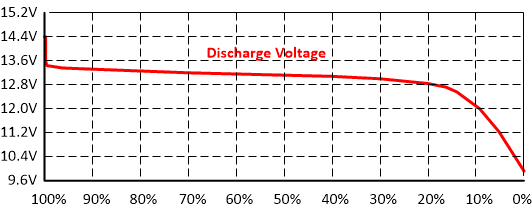

...that link has a graph of battery voltage while discharging, though

it must be recognized that this is dependent on the discharge current.

The graph is reproduced here:

The Battery Management System (BMS) built-in to the battery will

automatically disconnect the output if the voltage falls below a certain

value -- from a bit of reading, this seems to be in the range of 2.5 to

2.8 volts per cell, which will be 10.0 to 11.2 volts for a 12 volt

battery.

My Amptron 50AH battery has a BMS that turns the battery off at 10.0 volts.

The coulometer setup allows entry of a minimum voltage, below which

the % charge will immediately drop to 0%. So, how about 11.2V?

OK, I have done that, have programmed 11.2V as the 0% limit in the

coulometer. This will give an automatic correction when discharging the

battery. The battery will be down at around 5% actual charge to trigger

this.

Discharging a LifePO4 battery to 5% SoC will reduce the lifetime, but

this should be a correction factor that is only triggered occasionally.

Hopefully. Even if it is triggered often, I will still expect to

get about 2,000 cycles, and even if I cycle the battery every day, it is

going to last several years.

One more point to make about coulometer setup: does a battery rated

at "50AH" actually deliver 50AH? If not, then the capacity entry in the

coulometer will have to be adjusted accordingly.

It should be noted that the "error creep" that I have reported in this post is a known problem, and it occurs on many devices, such as mobile phones and electric scooters.

Tags: nomad

Powerbox front-page in nomad section

I have created a front-page for the lithium powerbox project, in the "nomad" section of my website:

https://bkhome.org/nomad/barrys-lithium-powerbox.html

The nomad section is a gradual accumulation of documents for and

about "nomads", especially "grey nomads" -- these are people who have

chosen an alternative lifestyle on-the-road, periodically or permanent.

Here is the front-page to the "nomad" section:

Ha ha, I am in lockdown, as are all the grey nomads in Australia, but restrictions are easing.

Tags: nomad

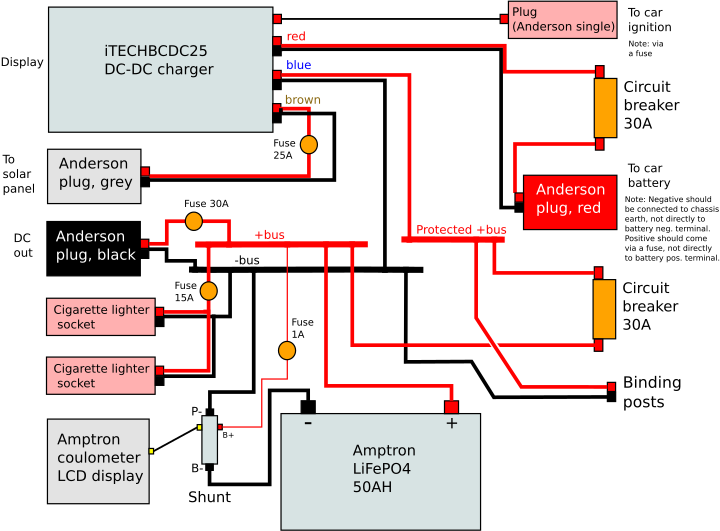

Powerbox circuit diagram updated

As the "protected +bus" has been added, and the binding-posts are

not shown in the original circuit diagram, I have updated the diagram:

The earlier blog post has been edited and the latest Dia and SVG files posted:

https://bkhome.org/news/202004/powerbox-fuse-redesign.html

Tags: nomad

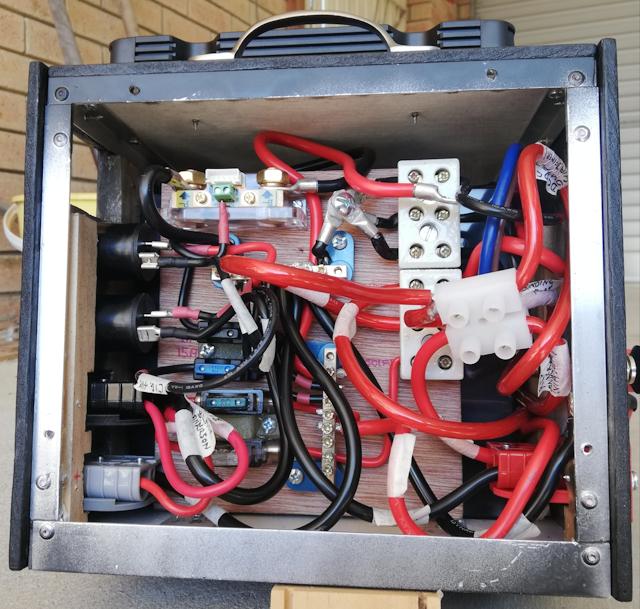

Lithium powerbox photo-shoot

The powerbox is complete, for now anyway. There have been a

series of blog posts as the project progressed, and the intention is to

create a front-page for the project, that will link to all of the blog

posts, in the correct sequence for anyone who wants to build one.

Here is the previous post:

https://bkhome.org/news/202005/itechbcdc25-dc-dc-charger-problem-resolved.html

There were some refinements to improve battery-terminal accessibility

and wiring-board layout, and I edited the second-from-last post:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

Now for a photo-shoot, with the powerbox posing at various angles for the camera:

Need to do some more testing of course, and go camping!

Tags: nomad

iTECHBCDC25 DC-DC charger problem resolved

In the last post in the lithium powerbox project, I reported a couple of issues with the DC-DC charger:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

I sent an email to iTECHWORLD Service department, reporting two problems:

- The battery-type selector button did not work, it was stuck on "calcium"

- The MPPT regulator was not tracking at the peak power point of the panel

I received a reply from Jason, that has resolved the first issue, number-2 is looked at a bit more today.

Before receiving the reply from Jason, early this morning I thought

it necessary to perform a more thorough test of the DC-DC charger, solar

charging...

Nice sunny day today, last chance as rain forecast over the next

several days. In fact, almost exactly one year ago, on an almost

identical day, mid-winter, sunny, hardly any breeze, ambient 16 degC, I

tested three solar panels, including the Atem Power "250W" panel:

https://bkhome.org/news/201905/measurements-for-three-solar-panels.html

...and recorded a peak power output for the Atem Power panel of 157.2W.

MPPT charging

Early this morning, Friday 1st May, 2020, 9.10am - 9.30am, have

tested charging the iTECHBCDC25 with this same panel. Ambient is 17

degC, irradiance is 820W/m2 -- a year ago it was almost the same,

800W/m2.

As the DC-DC charger is stuck on "calcium" battery type, I used my

Waeco Coolpower 44 battery box, which has a deep cycle 44AH AGM battery,

a closer choice to the calcium charging profile than the lithium

battery. Here is a photo:

As the battery is fully charged, I loaded it down by a 40W globe

running via an inverter. The panel was outputting 20.3V at 4.99A (101W),

and the battery voltage was 14.7V.

I needed to load the battery down a bit more, bring down the battery

voltage, so that the DC-DC charger will think the battery

state-of-charge is low, and will then pull everything it can from the

panel. So I attached my air compressor. Now getting 15.4V at 9.6A (148W) from the panel, battery voltage 12.1V.

Good, but a year ago, I determined the peak power point of the panel to be 16.21V, power output of 157W. So that issue is still there, the iTECHBCDC25 is pulling at a bit off the peak power point.

But, to be 100% certain about this, I really should test for the peak power point at the same time as testing with iTECHBCDC25.

Battery-type

Moving on, the issue of the battery-type button being stuck on "calcium". Here is a photo:

Fast forward to this evening, I read my emails, and here is the reply from Jason:

...riiiight. Tonight, I used the Waeco Coolpower as the "car

battery", connected to the red and black cable of the iTECHBCDC25, and

hey, was able to change to "Lithium" type. Good, but the User Manual

does not state that the "car battery" only has to be connected. Quoting

from the User Manual:

SOLAR INPUT

Once correctly installed, the iTECHBCDC25 has MPPT solar

charging for increased solar efficiency.

Once your solar panel has been connected to the solar

input section of the iTECHBCDC25 the charger will

transfer to solar mode when the vehicle is not running.

The initial default setting is for AGM/GEL batteries.

If you are charging a battery of a different chemistry

simply change the battery type by pressing the battery

type selector button on the front panel of the

iTECHBCDC25.

Once you have selected the new battery type the

iTECHBCDC25 will remain on this battery type until it is

changed.

Solar charging requires a solar input of 16 to 25v.

Your solar panel will need to be unregulated when

connecting to the iTECHBCDC25.

Well, that is a relief, the charger is not broken.

Tags: nomad

DC-DC charger issues and powerbox improvements

Ha ha, I am an inveterate tinkerer -- in the sense of always

wanting to experiment, modify and improve whatever I have designed and

constructed. In fact, the journey is often as much or more fun than the

destination. Camping, for example -- preparing for camping is as much

fun as actually going camping.

Nice sunny day, so this morning took the powerbox outside and

connected the Atem Power "250W" solar panel. Yes, it does charge, but

there are two serious issues. I have sent an email to iTECHWORLD

technical support, and will await their response before deciding if

these "issues" can be described as faults. Stay tuned for developments.

The previous blog post for this powerbox project:

https://bkhome.org/news/202004/installation-of-the-coulometer-lcd-display.html

In earlier posts, I have identified some limitations in the physical

design of the powerbox and the wiring layout. Decided to fix them,,,

Getting at those battery terminals is just too awkward and dangerous.

The top-plate of the box is screwed on from the underneath. In

retrospect, this was dumb, but there was a reason originally -- wanted

to place the DC-DC charger flat on the top of the box, without

protruding screws getting in the way.

Screwing from the top allows the screws to be removed and top panel

lifted off. This allows access to the battery terminals. So, I pulled

off all of the side panels, removed the screws holding on the top panel:

...yay, easy access to the battery terminals. You can't see the

positive terminal in the photo, as it is covered with black electrical

tape.

Late night right now, tomorrow will apply screws from the top. It

will be easy to remove them and lift up the top panel any time it is

desired to access the battery terminals, or anything else.

Another problem is that extra terminal block just floating there, looking messy, see this earlier snapshot:

Another task for tomorrow will be replacement of that floating

terminal block with a small busbar mounted on the spare space on the

wiring-board. And a bit of a tidy-up of the wiring.

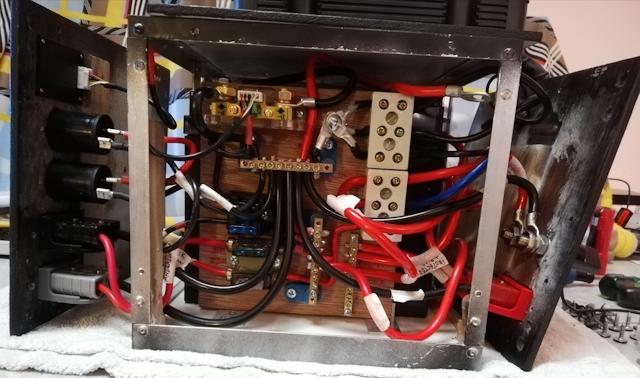

EDIT 2020-05-02:

The top plate has been modified, with screws on the top, so that it can be opened up. I have edited the original blog post:

https://bkhome.org/news/202004/top-plate-of-lithium-powerbox.html

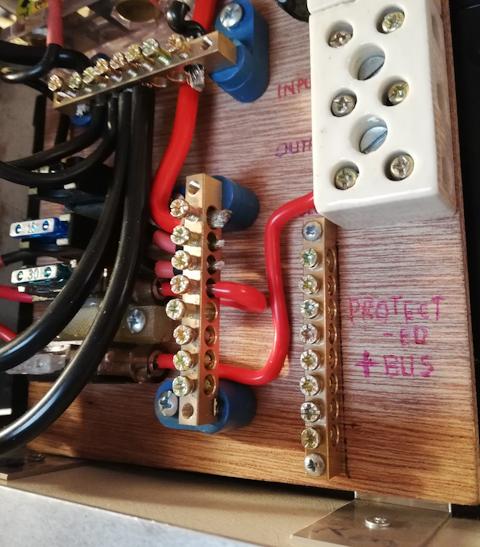

To get rid of that floating terminal block, I

have installed "protected +bus", using one of the 8-way busbars from

Jaycar, though (currently) only need three ways:

"+bus" is connected directly to the battery

positive terminal, whereas "protected +bus" is on the other side of a

30A circuit breaker. Or rather, is, once it is wired up:

And, after screwing the front and back panels into place:

That is better. It is still crowded of course, but that was part of the exercise, to build a very compact powerbox.

Tags: nomad