Top-plate of lithium powerbox

The plywood floor is 235x225x9mm, with 12x20x1.5mm angle assembled around it, see previous blog post:

https://bkhome.org/news/202004/base-of-lithium-powerbox.html

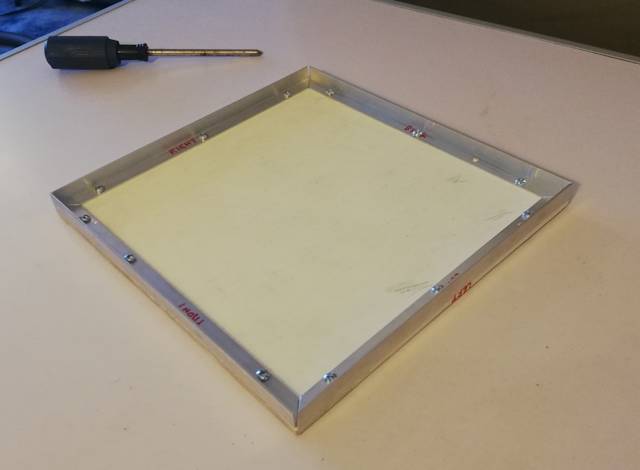

The top of the powerbox will be a flat surface. This is plywood

measuring 238x228mm (3mm longer on both sides than the base plate). In this case I have used 6mm ply, which will also

be used for the sides. It is just that I have 6mm marine ply in my

garage, and want to make use of it.

I also have some 12x12x1.5mm angle in the garage, so have used that around the edges:

...that is upside-down. Here it is the right-way-up:

The screws are 6G 9mm dome-head, for metal and wood, which meant the

tips stick out the other side of the plywood. However, it was easy to

file the metal tips flat to the surface.

This gives me a completely flat surface on top, on which the DC-DC charger will be mounted, plus two grab-handles.

A practical detail for anyone in the future who might follow these

plans to build their own powerbox: if you cut the pieces of aluminium

angle too short, no problem as they will be hidden by external plywood

cladding.

On the other hand, if a tad too long, a simple way to grind the end is like this:

I used coarse sandpaper, 40-grit. The sandpaper is intended for

sanding wood, but worked OK grinding aluminium -- the grains did not

come off. The trick to doing it is press firmly with the finger closest

to the end, and drag towards you -- pushing away from you does not work

so well.

The top and bottom plates require corner posts. These are angle

pieces riveted on the inside corners. I used 12x12x1.5mm angle, 30mm

long. The rivets are aluminium 3.2x3.2mm (requiring a 3.2mm, or 1/8

inch, drill bit). Here they are installed in all corners:

Another practical detail: I used two "clamping pliers" to hold the

corner posts while drilling. Otherwise, you could use a small block of

wood and g-clamps.

EDIT 2020-05-01: Important design change

After building the powerbox, I found a very big problem, it was very

difficult to access the battery terminals. The fix is to make the

top-plate removable.

Which it isn't as shown in the above photos, as the screws are

underneath, inside the box. So, instead, screw from the top, through the

plywood into the aluminium.

Please see this post, that shows the final box with battery inside:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

The box will then have removable panels on all four sides and the top. The screws used are 8G 15mm button-head timber screws:

The drill bit used is 2mm. The wood screws are able to self-tap into the aluminium.

Placement of the screws needs to be thought about. I placed them 8mm

in from the edges of the plywood, and they need to be placed so as not

to be underneath where the DC-DC charger is proposed to be located.

Also, there are two handles on the top, which will also have screws that

tap into the aluminium.

Tags: nomad