Installation of the coulometer LCD display

The previous post in the powerbox project:

https://bkhome.org/news/202004/wiring-board-installed-in-powerbox.html

The finishing touch is to install and calibrate the Amptron

coulometer. As already discussed, the shunt is already mounted on the

wiring-board. This is what I have:

https://www.amptron.com.au/100a-coulometer---battery-monitor-with-shunt.html

If you search on eBay and elsewhere, for "battery coulometer", you

will find this available from many vendors, and there are also setup

videos on YouTube.

Installing the coulometer

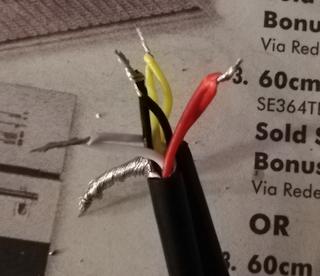

There is a shielded cable to connect the shunt to the LCD display,

and this is a problem, as it is very long. This is for the situation

where you want the display somewhere else, maybe on the dashboard of the

vehicle, or whatever.

I want to cut it right down, as the LCD display is close to the

shunt. So, I cut the plugs off each end, and joined the cable. I am

familiar with delicate electrical work, as I was an electronic engineer

in my working days. I have a small soldering iron and fine solder for

the purpose. The wires inside this cable are so tiny, this photo blows

it up, but in actuality they are so tiny. The photo shows after I have

stripped each wire and twisted them together:

...I then very carefully soldered each join, then put heatshrink

tubing over each join, then bound it all together with electrical tape.

I know that such delicate work will be a challenge for many -- well,

you could just go and buy a ready-made powerbox! But it is not

insurmountable. The wires are so tiny, I stripped them with my

thumbnail, pressing onto the table -- my cable stripper does not handle

such tiny wire.

Calibrating the coulometer

I watched one of the YouTube videos on how to calibrate the

coulometer, but it is misleading. They set "full" and "empty"

corresponding to certain battery voltages, but this could be very

inaccurate.

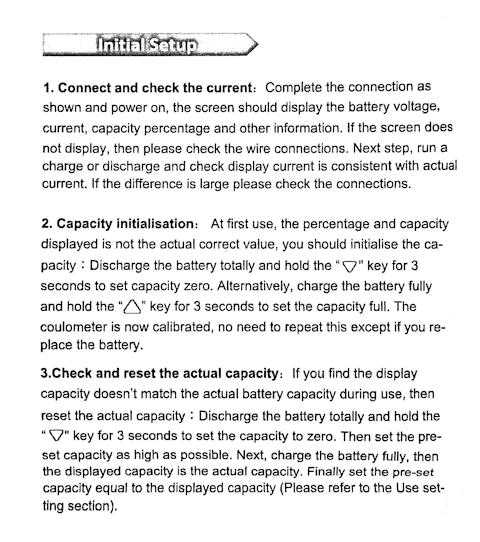

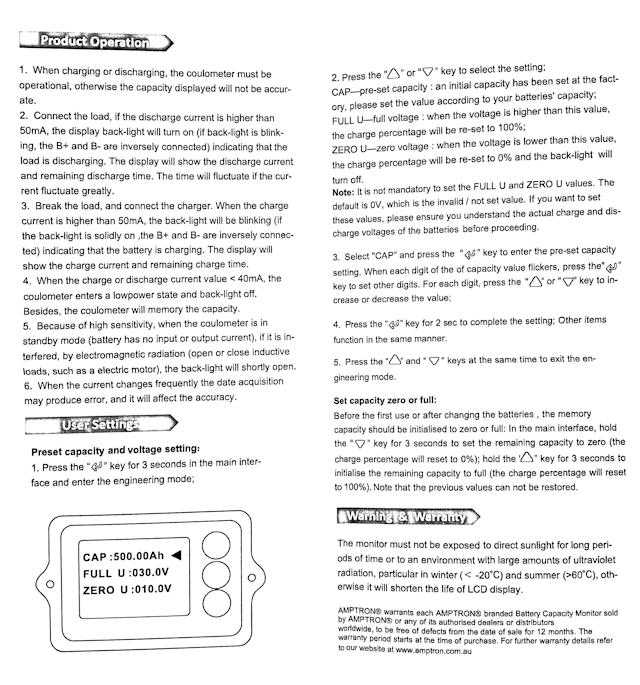

Here are the instructions:

What I did was first charge the battery to 100%, using the Amptron mains-input lithium 15A battery charger:

https://www.amptron.com.au/15a-12v-lithium-lifepo4-battery-charger.html

...this has eyelet lugs, that I replaced with a black Anderson plug

-- very convenient, just plug it into the powerbox, and it will charge

until 100%.

Following the above instructions, I then pressed the "up" key for three seconds to set the display at 100%.

Following the "User Settings", I then chose battery capacity as 50AH

-- note, the buttons have to be very firmly pressed, and getting out of

"engineering mode" proved to be difficult.

That's it, I did not set "FULL" and "ZERO" voltages, as that is not a reliable indicator of 100% and 0%.

Using the coulometer

I plugged my Powertech 150W inverter (purchased many years ago from

Jaycar, and used on many camping trips) into a cigarette lighter socket,

and plugged in a desktop lamp:

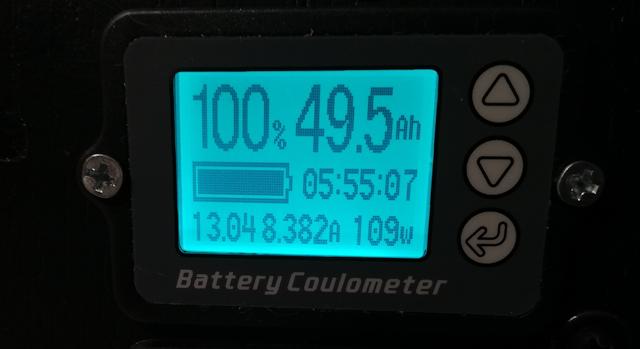

Fantastic, working! Here is the LCD display:

Very nice! That snapshot is after running the lamp for a short time, the capacity has dropped a bit below 50AH.

EDIT 2020-05-04:

After further reflection, I decided it is a good idea to minimize "error

creep" of the State-Of-Charge, by setting a lowest voltage for 0%. See

this later post:

https://bkhome.org/news/202005/coulometer-error-creep.html

Tags: nomad

Wiring-board installed in powerbox

In the previous post, I wrote about some compromises when wiring-up the wiring-board:

https://bkhome.org/news/202004/reflections-on-construction-of-the-wiring-board.html

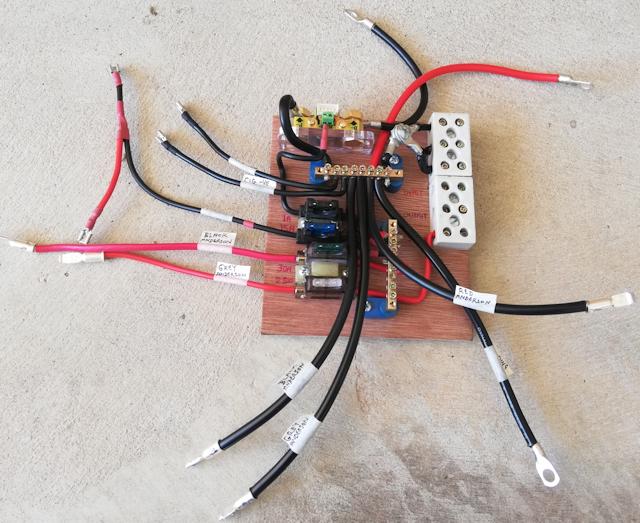

Now for some photos showing the wiring-board installed. Firstly, here is the wiring-board all ready to be installed:

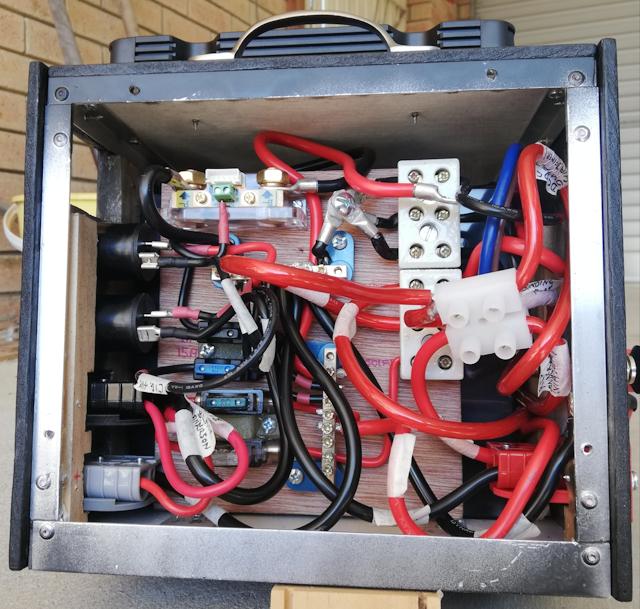

And here it is installed:

...quite crowded, but more so because of that extra terminal block.

The previous post discussed how that could have been improved, with a

distribution bus mounted on the wiring-board -- there is some space

bottom-right of the board.

I also discussed in the previous post, the limited space to access

the battery terminals. The unconnected eyelet lug in the above photo is

waiting to be bolted to the battery positive terminal. I managed, just,

and solutions to obtain better access are mentioned in the previous

post.

EDIT 2020-05-02:

Both of these problems, battery terminal access and messy floating terminal block, have been fixed. See this later blog post:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

Tags: nomad

Reflections on construction of the wiring-board

Continuing the powerbox project, previous post:

https://bkhome.org/news/202004/battery-insertion-and-more-bits-and-pieces.html

The wiring-board has been completed and inserted into the powerbox.

There are a couple of places where I improvised, due to not having the

type of connectors desired...

DC-DC common earth

Top-right of the wiring-board, there are two porcelain terminal

blocks, These will take the wires from the DC-DC charger. The DC-DC

charger has three earth wires (black wires), a "DC input" (red wire), a "DC output"

(blue wire) and "Solar input" (brown wire) wires. The three earth wires

(let's call them "cables" from now on) are electrically connected

together inside the DC-DC charger, so theoretically we only need one of

them. However, for the lowest possible resistance path, I have joined

them via the top terminal block, hence to the "-bus", like this:

...originally, I was going to daisy-chain the left-side terminals,

however, the holes aren't big enough. So, improvised with eyelet lugs

bolted together. What would have been ideal is this (instead of the

porcelain block):

https://www.amazon.com.au/Square-Schneider-Electric-PK4GTACP-Terminal/dp/B00173B1LQ/

...however, that ships from the USA, currently not practical to buy.

This also looks good, though not sure where it ships from (and ideally I

want one that can be affixed to the board, which this doesn't have):

https://www.amazon.com.au/uxcell-Positions-Electric-Distribution-Terminal/dp/B01LWTXOW0/

Incidentally, that 8-way busbar that I have used, two of them, is available in 6-way. Again, I don't know about delivery:

https://www.amazon.com.au/AUTOHAUX-Positions-Terminal-Grounding-DC250V/dp/B07VMD6S3D/

Cable splitter

The second improvisation is splitting a cable. The "DC output" goes

via the porcelain terminal block, to one of the 30A circuit breakers,

hence to the "+bus" busbar. However, I wanted to branch "DC output" to

the +ve binding post -- a convenient place to pickup the +ve voltage

with protection of a circuit breaker.

I cut off two segments of a 60A terminal block, and wired like this:

...you can see "DC-DC output" label, which comes from the "DC output"

of the DC-DC charger. The other side goes to a 30A circuit breaker,

hence to the "+bus". My klutz was to insert two cables into the

left-side of the terminal, bringing out another cable to go to the +ve

binding post.

A 3-way distribution bar mounted on the wiring board would have been far neater.

See bottom-right corner of the photo, "Red Anderson" label. This is

from the other 30A circuit breaker, the other side of which is wired to

"DC input" of the DC-DC charger. As all the cables from the DC-DC

charger and 30A circuit breakers are just bare ends, I need an Anderson lug -- the other terminal

on the terminal block joins a short length of cable with an Anderson

lug on the other end.

This also could have been simplified. The terminal block join could

have been eliminated by soldering an Anderson lug directly onto the

cable from the 30A circuit breaker -- just might need a bigger hole in

the back panel for the cable to feed through to the circuit breaker.

That extra terminal block does look a bit untidy, and clutters things somewhat, but it does the job.

EDIT 2020-05-02:

The messy floating terminal block has been fixed, see this later blog post:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

Tags: nomad

Battery insertion and more bits and pieces

The previous post was "bits and pieces" information about construction of the lithium powerbox project:

https://bkhome.org/news/202004/cable-and-soldering-guidelines.html

This post is notes about battery insertion, and various notes about

connectors. In a previous post, I had discussed concerns about the

current capability of some blade fuse holders, and I also mentioned that

spade terminals might not be suitable above 10 amperes -- today's post

has more on this.

Today I inserted the Amptron 50AH lithium battery into the powerbox.

The front and back panels have to be taken off, for insertion of the

bracing bar that will hold the battery down:

Construction of the bracing bar is described in an earlier post. You

can see it in the above photo, with a bolt that will be adjusted to

provide tension. The bracing bar is 10x10mm aluminium channel, and the

bolt is M4 16mm hex head, purchased from Bunnings:

I used two nuts on each bolt, to lock the nuts.

The battery is held firmly, but just in case, to stop horizontal

creep, I put two pieces of old foam at each end, and on the side of

battery facing the the front panel, put two pieces of 12x20 angle:

WARNING:

As the frame is made with aluminium, I placed electrical tape over the

battery terminals before inserting the battery. Advice to everyone: do

not skip this step!

Also, I wrapped electrical tape around the spanner, for doing-up the terminal bolts. Again, important precaution.

Which reminds me: in a previous post, I suggested that an extra 5mm

height for the box would be an improvement. Yes, I have slim fingers,

but it was difficult to get into the narrow gap between top of battery

and top-inside of the box. Someone with chunky fingers would find it

impossible. Make that an extra 10mm.

Oh, and about the spanner, do not use an adjustable spanner. A proper

flat 13mm (for the Amptron battery) spanner is required. There is just

enough space to slip a spanner over the hex head of the terminals, and

very little swing to tighten it.

At the risk of being overly-verbose in this post, another thought has

occurred to me. I did also mention in an earlier post that a wood frame

might be better than using aluminium. It certainly would be safer when

inserting the battery and accessing the terminals (note, I have not

connected the aluminium frame to either +ve or -ve, which does make it

safer). With a wood frame, the top plate of the box could be screwed

from the top, such that the top plate could be lifted off, thus giving

easy access for both inserting the battery and doing-up the terminals --

worth considering!

I do have thoughts how to design the wood frame, and if anyone wants

to go that way, contact me. Or, if you create a design, let me know and I

can post it.

Now for some connector details...

Washers

The bolts on the battery terminals do not screw all the way down, and

require washers. I have used two washers plus the cable eyelet-lug. The

binding posts also require an extra washer on each. The washer that I

have used for both situations is this:

https://www.bunnings.com.au/pinnacle-m8-stainless-steel-flat-washer-12-pack_p0130534

Also used these in a couple of places, 3/16 inch and M5:

https://www.bunnings.com.au/zenith-3-16-zinc-plated-machine-washer-50-pack_p2420280

Eyelet lugs

Eyelet lugs are required for battery terminals, binding posts,

coulometer shunt, and the 30A circuit breakers. I purchased these two

sizes from Jaycar:

https://www.jaycar.com.au/6mm-non-insulated-eye-terminal-6mm2-pk-8/p/PT4934

https://www.jaycar.com.au/8mm-non-insulated-eye-terminal-10mm2-pk-8/p/PT4936

Spade terminals

I have posted earlier about current capability concerns. As I am

soldering all connections, not crimping, I purchased these female spade

connectors:

https://www.jaycar.com.au/6-3mm-non-insulated-spade-connectors-pk-10/p/PT4630

However, they have very thin metal, and I could feel they had less

grip compared with others that I already have. Those others are going to

be much more suitable for currents up to 15A, but unfortunately are

only available as crimp-type:

https://www.jaycar.com.au/female-spade-yellow-pk-8/p/PT4707

...the plastic covering is very tough, can't even get it off with a

hacksaw, so used my soldering iron to cut down its length. I then had

naked connectors, to which the cable can be soldered. Note, these

connectors will take up to 6mm auto cable.

Rubber feet

The wiring-board is not going to be bolted to the box, instead will

rely on everything around it to keep it in place. There are screws

sticking out the back of it, and as the back side will be against the

battery, I screwed rubber feet onto the back side of the board. These

ones:

https://www.jaycar.com.au/11mm-screw-fixing-rubber-feet-pk-8/p/HP0800

Final product notes

Tomorrow the plan is to do some finishing touches to the assembly,

and powerbox will be ready to go. It is anticipated that the next blog

post will be about the final assembly.

An interesting point about practical usage: the completed powerbox

weighs just on 11kg, which is OK for me, but I wouldn't want to lug

anything heavier. The battery is 50AH, effectively equivalent to an 80AH

AGM battery, which is also OK for me -- but what if one day in the

future, I want to run more things off the battery, or find myself in

situations where there are many days without sunlight, and want more

battery storage?

No problem, just attach another battery. What I would need is another

50AH lithium battery, in a box, with fuse and short cable with a black

Anderson plug. Plug it into the black Anderson plug on my powerbox, and

hey presto, power storage is doubled (make sure both are full-charged

beforehand!). Having two separate boxes is also easier to lift.

My Amptron mains-input lithium battery charger will also have a black

Anderson plug, and can be used to charge either battery.

Tags: nomad

Cable and soldering guidelines

Continuing the lithium powerbox project, this is the previous post:

https://bkhome.org/news/202004/holders-for-blade-fuses-in-powerbox.html

Today's post has some bits and pieces of information about electrical circuit construction techniques. Those who are skilled with soldering, etc., will be OK to construct a powerbox like mine. Others, however, might need some hints.

Cable sizes

I have used various sizes of cable in the powerbox, as you can see in photos posted in earlier blog posts:

https://bkhome.org/news/202004/holders-for-blade-fuses-in-powerbox.html

...the thinner cable is "6mm auto cable", purchased from Big Als via

eBay. This has copper area of 4.59mm2. The thicker cable is two types,

purchased from Altronics. I do have some 8AWG from Big Als, however that

is twin core, besides, I want to use that for extension leads. So I

popped into Altronics and bought one metre of each of their "61A" and

"90A" power cables, red and black. Here are links to the red cable:

https://www.altronics.com.au/p/w4100-630-0.12-red-61a-power-cable/

https://www.altronics.com.au/p/w4216a-119-0.30-90a-red-power-cable/

The differences between these is very interesting. The 61A cable has

thinner strands, which makes the cable more flexible. Here they are

compared with 6mm-auto and AWG sizes:

| Cable type |

Copper area (mm2) |

| 6mm auto |

4.59 |

| 10 AWG |

5.26 |

| 9 AWG |

6.63 |

| W4100 61A |

7.1 |

| 8 AWG |

8.36 |

| W4216A 90A |

8.4 |

Much more expensive buying locally, but ordering over the Internet is

currently very slow, as vendors such as Big Als are based in the

Eastern States. I have used both of those cables from Altronics, using

up what has been purchased.

Soldering

Soldering technique varies, according to individual style. I prefer

the old-school copper tips on soldering irons -- modern irons do have

copper tips, but they are coated with something -- that I file off to

expose the copper -- as I find that solder sticks better to the copper

surface. The copper corrodes, which is why it has the coating,

but I use a file to keep the copper tip clean and flat. I also prefer a

chisel-tip.

This is the iron that I am using for this project:

https://www.bunnings.com.au/tradeflame-60w-240v-soldering-iron-kit_p5910275

...60 watts is more than enough for soldering 8 AWG cable. I use a

wet cloth to wipe the tip of the iron, but it would be nice to have this

one, with stand and sponge:

https://www.bunnings.com.au/tradeflame-30-60w-soldering-iron_p6270385

I do not own a crimping tool, so all joins are soldered. Eyelet lugs

and Anderson plug lugs are connected to cables by the flood-fill method.

See demo here:

https://www.youtube.com/watch?v=6IjG6-PxNBs

...difference for me though, is I apply solder to the expose cable

ends, before inserting. This ensures that solder has flowed through all

the fine wires in the cable, avoiding what is called a "dry join".

The video shows a flame being used to heat the Anderson lug. As I use

a soldering iron, just a dab of solder on the flat surface of the

chisel-tip, held against the side, will heat the wall and the solder can

be inserted -- as the video says, take care not to overfill, otherwise

it will overflow and run down the outside of the lug, perhaps rendering

the lug unusable.

I also solder the ends of the cable that is inserted into screw

terminals. This strengthens the cable, as the twisting action of the

screw can break the fine wires, plus some wires thrust to the side of

the screw are not tightly bonded electrically to the terminal.

Regarding solder, for this fairly heavy work, I prefer 1.6mm thick solder, available from Altronics:

https://www.altronics.com.au/p/t1122-1.6mm-200gm-roll-60-40-leaded-solder/

...Jaycar, only has 1mm solder. Bunnings, on the other hand, only stock much thicker solder, used for plumbing.

Cable splicing

The iTECHBCDC25 DC-DC charger came with Anderson plugs, that I cut

off. It also came with three more Anderson plugs with short lengths of

cable. I need to extend the length of the cables coming out of the DC-DC

charger, so I used the short lengths that were attached to the other

three Anderson plugs. The cable is 10 AWG.

The most common way that two cables are joined together, what we call

"spliced", is a special metal sleeve, which is then crimped. I have

neither the sleeves nor a crimper. Instead, I used this simple method --

just push the two ends into each other.

Doing this, the strands become intertwined, and it will grip

together. Note, I haven't tried this with the ultra-fine copper strands

in the Altronics "61A" cable -- perhaps it might not work. This slightly

out-of-focus photo shows the two cable ends pushed together:

It is then easy to solder, and forms a very strong bond. Heatshrink

tubing needs to be slid over the join. many years ago, I bought a pack

of mixed sizes, and the largest, 6.4mm, fits over 8 AWG cable. Ah yes,

it is still available:

https://www.autobarn.com.au/narva-heatshrink-selection-3-2-6-4-56600

So, there are six Anderson plugs that I have removed the lugs from. I

have plenty other Anderson plugs, but if I wanted to re-use these, it is

possible to buy the lugs, in packs of 20, from eBay.

Tags: nomad

Camping now allowed in WA

In Western Australia we had zero new cases of Covid-19 for three

days, then yesterday there was one, a lady who arrived back from one of

the cruise ships. As long as she hasn't started a new outbreak, things

are looking very good, attributed to the very sensible restrictions

imposed by the WA State government.

Consequently, the Premier today announced some easing of restrictions ...including allowing camping!!!

The eased restrictions are announced here:

Quoting:

non-contact recreational activities such as private picnics in the park, fishing, boating, hiking and camping − all in compliance with travel restrictions and the 10-person rule

WA is broken into regions, and we are still only allowed to drive

within the region in which we live. There are DPAW campsites within the

Perth/Peel Region -- but perhaps lots of people will be taking the

opportunity to go to those campsites.

The main point is though, in theory I can now go camping. Just need

to find a nice bushland or coastal spot within my region, that will not

have many others also camping there.

Got to finish the powerbox first!

Tags: nomad

Holders for blade fuses in powerbox

I posted yesterday about the start of wiring the powerbox, and a problem with using blade fuses at 20-30 amperes:

https://bkhome.org/news/202004/wiring-of-powerbox-underway.html

Originally, I had purchased this blade fuse holder 4-way box:

https://www.autobarn.com.au/narva-fuse-box-blade-54420bl

However, after watching the Redarc video (see above link), I became

concerned. The Narva packaging has "Maximum 30A per circuit", and if you

believe that, then you could put a total of 120A through it, 30A per

fuse.

I did a bit more reading on the topic, and it looks like the 6.3mm

spade terminals, as used in the above Narva fuse box, are only designed

to handle 10-15A. A 6-way blade fuse box sold by Jaycar, which, apart

from having 6 slots looks identical in its internal construction to the

Narva box, states "15A/circuit max" and "45A/block max":

https://www.jaycar.com.au/automotive-fuse-box-6-blades/p/SZ2002

Jaycar have these female spade terminals, rated at 10A maximum:

https://www.jaycar.com.au/6-3mm-non-insulated-spade-connectors-pk-10/p/PT4630

Comparing different blade fuse holders and spade terminals, some are

thicker metal, and appear to be designed to handle higher current.

Looking at what blade fuse holders are on offer, some indeed are

thicker metal and grip the fuse more firmly. I bought two of these

inline blade fuse holders:

https://www.jaycar.com.au/standard-duty-30a-blade-fuse-holder/p/SZ2040

...these have superb grip on the fuse, and actually require some

force to fully insert the fuse. Good, but I want to mount these on my

"wiring-board". That board is 150mm horizontal by 170mm vertical, 6mm

thick marine ply, and I posted a photo of the start of wiring it in the

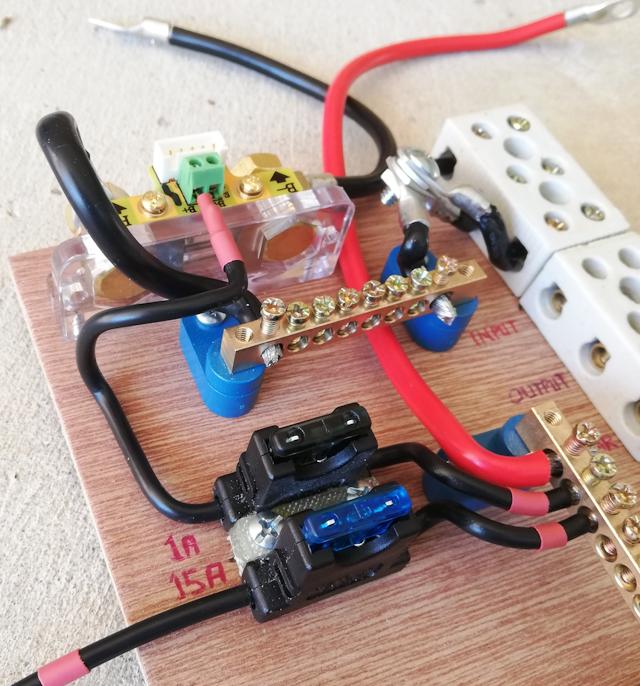

previous blog post. Here is a photo with two of the inline blade fuse

holders mounted on the board:

...overkill using that heavy-duty fuse holder for the 1A fuse. To

mount these fuses on the board, I used Selleys "All Plastic Fix" glue

and a small piece of plastic cut off a chopping board.

I have used that Selleys glue on previous projects. It consists of a

primer-stick and an adhesive tube, and will glue all types of plastic,

giving a very strong bond. The primer-stick lasts a lot longer than the

adhesive, and I was reading somewhere, someone just used superglue and

it worked the same as the All Plastic Fix adhesive tube.

The 1A fuse goes to the coulometer, via the shunt. The 15A fuse will

go to the cigarette-lighter sockets. I still have to put in fuse holders

for the DC-output black Anderson plug, and for the solar input grey

Anderson plug -- these will be 30A and 25A fuses.

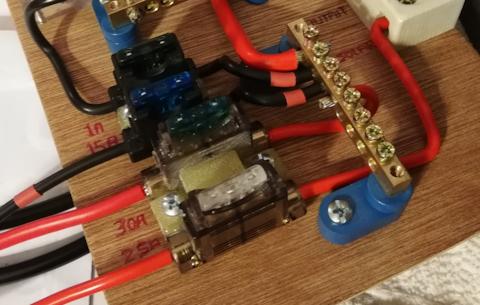

EDIT 2020-04-26:

Fuse holders for the 30A and 25A blade fuses have been added to the board:

I wanted screw terminals, so chose these:

https://www.jaycar.com.au/screw-terminal-30a-blade-fuse-holder/p/SZ2044

These blade fuses need even more force to

insert than the other ones, so it is a very good connection between fuse

and holder, so I am confident these will handle 30 amperes. The screw

terminal holes look like they will take up to 9 AWG -- I have just

noticed that the table here has the wrong area for 9 AWG cable -- it should be 6.6mm2.

Same construction, the two fuse holders have

been glued together for mounting on the board. Given the force to insert

and remove fuses, I put an extra piece of chopping-board plastic to

more securely bond the two holders together.

The two red cables going out to the left, have

Anderson plug lugs on the ends, for insertion into the black and grey

Anderson plugs.

Tags: nomad

Wiring of powerbox underway

I have started the internal wiring of the lithium powerbox, and

this post is a progress report. Here is the previous post for this

project:

https://bkhome.org/news/202004/powerbox-external-assembled.html

It is progressing slowly, but surely. I had to pause for awhile to

think about some construction details. Anyway, here is a photo showing

the wiring so far:

...notice that the box is now painted black! I used a cheap "flat black" enamel paint spray can.

A change from the previous photo (see above link) is that I removed

the Anderson plugs from the DC-DC charger and cut a round hole for the

cables to go into the box. Next to the round hole is "half" of an

Anderson plug -- this is for the wiring to the vehicle ignition key.

The wiring-board is propped alongside the box, for the photo.

Top-left of the wiring-board is the shunt for the coulometer, the two

black and red cables sticking out the top will go to the battery.

The "+bus" and "-bus" busbars were purchased from Jaycar:

https://www.jaycar.com.au/machined-brass-busbar-8-way/p/SZ2003

The terminal blocks at top-right are for wiring to the DC-DC charger. I purchased porcelain blocks:

https://www.jaycar.com.au/3-wire-porcelain-terminal-block-30-amp/p/HM3185

...however, afterward I noticed these, which would probably do the job:

https://www.jaycar.com.au/60-amp-12-way-screw-terminal-strip/p/HM3204

The blank space on the wiring-board is where the fuse holders will

mount. This is where I had some problems, as the blade fuse holders in

local shops, of the surface-mount terminal-block type, seemed too

"light" to handle 20-30 amperes. The engine-bay is a more extreme

environment, but this Redarc video does show the potential for

catastrophic failure when using blade fuses:

https://www.youtube.com/watch?v=kZ76NsvvBE0

Snapshot from the video, of a melted inline blade fuse holder and fuse:

I intend to post soon about what fuse holders I chose, and what got rejected.

Tags: nomad