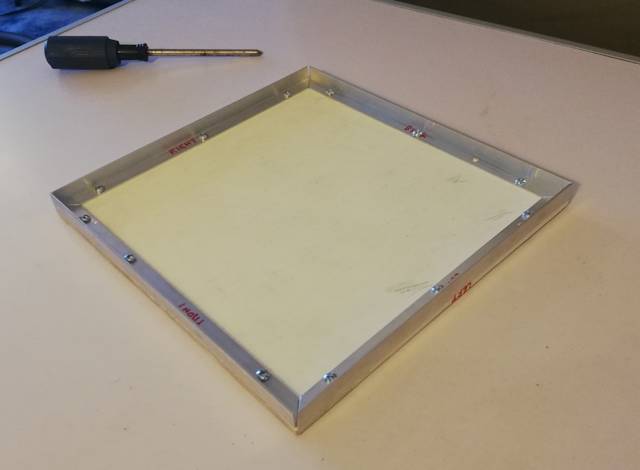

Powerbox external assembled

This is continuation of the new lithium powerbox project. Previous post:

https://bkhome.org/news/202004/powerbox-side-panels-and-battery-clamp.html

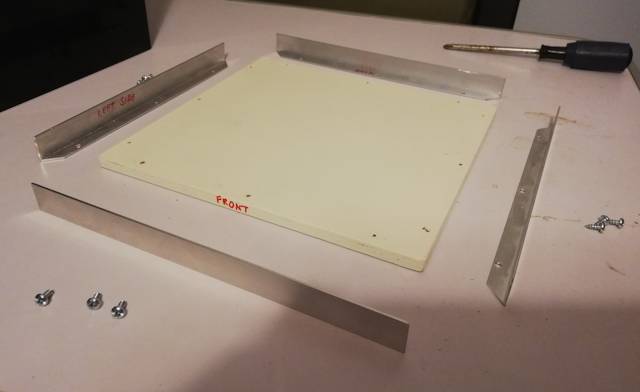

I have cut out the front and back panels, here it is assembled, front view:

...no internal wiring yet! Here is the back view:

So, in retrospect, am I happy with the design of the box? If it was done again, would I change anything? Yes...

- I used 6mm ply front and back, which is too thin. The Anderson plugs require considerable force to plug-in and unplug. I strengthened with some strips of pine screwed on internally, however, use of 9mm ply would have been better.

- Dimensions are a tight squeeze. OK, but if someone wanted to use a slightly different battery, it probably wouldn't fit. For my Amptron 50AH battery, I would have preferred an extra 5mm internal height, to make sliding in and out via the side easier -- though probably once it is in, it will stay in -- I expect the battery to outlive me.

- It might have been simpler and easier to go for a wood frame

rather than aluminium. Bunnings sell 12x12mm section medium-hardwood,

which would have done the job.

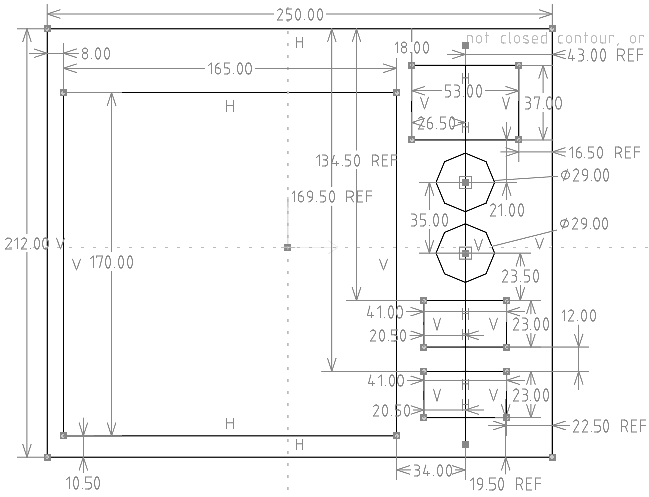

I used SolveSpace to figure out where to place the cut-outs on front and back panels. Here is the front panel layout:

...the 165x170mm rectangle is the internal battery, so there is

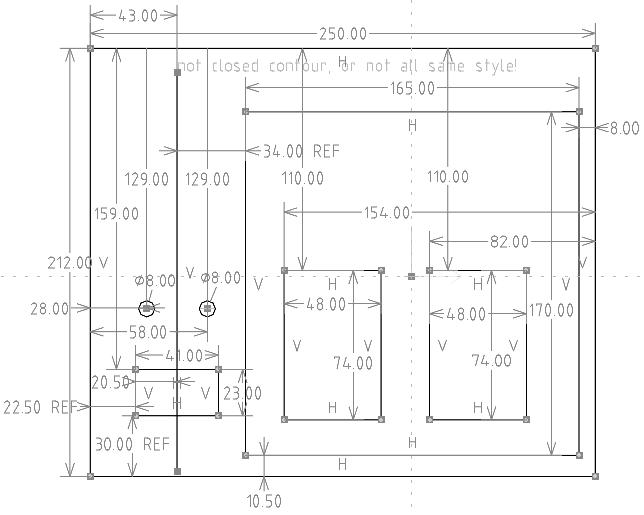

nothing cutout on the front panel in that area. Here is the back panel

layout:

...again, the battery is shown. The two 48x74mm rectangles are not

cut-outs -- that is where the 30A circuit breakers will mount

externally.

I painted it aluminium-silver, however, reckon that matt-black would

be more appropriate. Black would match the DC-DC charger, and some of

the power sockets.

There are a couple of details to finish off, before starting on the internal wiring.

EDIT 2020-04-21:

For the record, this is where I purchased some of the items screwed onto the front and back panels:

I ordered one of each colour of the Anderson

panel-mounts. The vendor agreed on one payment of AU$9.90 to ship all

three by Aust. Post Express (you have to ask for that):

This is the cigarette lighter socket:

https://www.jaycar.com.au/dash-panel-mount-cigarette-lighter-socket-with-cap-15a/p/PS2004

Binding posts came from Altronics:

https://www.altronics.com.au/p/p9225a-heavy-duty-red-50a-binding-post/

...they have holes for banana plugs, but

Altronics also have binding posts without the banana plug holes. Note,

the tops screw right off, so that eye-type lugs can be attached.

The externally-mounted 30A circuit breakers are

available from many places. They are very expensive from some local

vendors. I purchased via eBay:

EDIT 2020-04-22:

Here is another vendor of the flush-mount Anderson housings, at almost half the price. They stock grey, red, black and blue:

https://andersonconnect.com.au/store/index.php?main_page=product_info&cPath=36_72&products_id=352

Tags: nomad

Powerbox side panels and battery clamp

Here is the previous post in the new lithium powerbox project:

https://bkhome.org/news/202004/top-plate-of-lithium-powerbox.html

Today I cut out the side panels, and implemented a solution for holding the battery down.

Firstly, the side panels. These are 228 horizontal by 212 vertical,

6mm thick plywood. These will screw onto the sides, and be removable --

the left is where the battery will slide in, and the right is to access

the electrical wiring.

Pretty simple, cut them out using a tenon saw, drilled holes in an offset-pattern, and a coat of acrylic paint:

Out of curiosity, I contacted a local business that specializes in

custom perforated aluminium. Their quote for the same thing in

aluminium, 1.5mm thick, 40%-open pattern, was AU$80 + GST. That would

mostly be labour cost of course.

The battery needs to be held in place, both horizontal movement and

jumping vertically. I will put some angle to make sure it doesn't creep

horizontally. To stop jumping, I created two vertical posts:

...two pieces of 10x10x1.5mm aluminium channel, with 12x12x3mm angle

riveted to them. I used stainless steel rivets, for the extra strength,

which I think will be OK -- but if someone is following these plans, you

might consider using 12x20x3mm angle, with two rivets.

Um, Bunnings only have 12x12 and 20x20 in the 3mm thick angle. Here is the 12x12x3mm:

https://www.bunnings.com.au/metal-mate-12-x-12-x-3mm-1m-aluminium-equal-angle_p1067857

After riveting it into the box:

...10x10x1.5mm channel is used as the cross-piece. The clamping bolts

are M4 10mm hex-head, which is a very convenient size, as the hex-head

fits snuggly into the channel.

I have 10mm length, however might pop down to Bunnings and buy 16mm

length, so as to be able to use two nuts (to lock them in place):

Or:

The cross-piece is shown in the photo for illustration, but it would

only be inserted after the battery is placed inside the box.

So, what is next? Front and back panels I think.

Tags: nomad

Ready-made lithium powerboxes

My new project is a "lithium powerbox", see most recent post here:

https://bkhome.org/news/202004/top-plate-of-lithium-powerbox.html

It is interesting to see what is out there, ready-made. There are

many powerboxes, of varying capacities and features. Most of them are

designed to be portable and readily removed from the vehicle. One of the

biggest of these highly-portable types, that I know of, is a 60AH unit

made by iTechWorld:

...which is a very nice all-in-one solution, at an excellent price.

It has compromises, such as only charging via the cigarette light

socket, so probably limited to 10A charging. The documentation states

that it cannot be used when charging.

The more "hard core" solution is a powerbox that is intended as an

alternative to a permanently wired-in system. Many 4wd owners go the

latter route, with a custom permanently wired-in installation -- which

often looks very messy and may be space-inefficient.

The semi-permanent "hard-core" powerbox may be left permanently in the vehicle,

or taken out, perhaps if you are not going camping for awhile and need

the space for something else, or change to another vehicle. These

powerboxes are designed to charge directly from the car battery, at 20A

or more.

I did a quick survey of what is available in Australia, in this

"hard-core" category. One that I knew of from before is "The Lithium

Box":

http://rvlithiumsystems.com.au/Portable-Power/portable-power.html

...the smallest has a 100AH battery and weighs 21kg -- too heavy for me! I can't see prices anywhere.

A Perth company has put together the "National Luna" box:

https://perthpro.com.au/product/customised-national-luna-redarc-portable-battery-box-dual-battery-system-with-25a-dc-dc-charger/

...with Amptron 100AH lithium battery, price is AU$1,990. Weight is 18kg.

Here is another, the "JTS Power Easy" box:

https://jts12volt.com.au/product/lithium-dual-battery-power-easy-pack/

...price is AU$2,795, with 100AH battery. Weight is given as 55kg ...gulp!

But wait, there's more! If you would like a battery box with DC-DC

charger but without the battery, so that you can add your

battery-of-choice later (AGM or lithium), there is the "Kickass Premium

Battery Box", at AU$689:

...though, not yet available. ETA is August 2020. It is their DC-DC

charger that is holding things up -- it has been on pre-sale for a few

months. No doubt it is coming from China, and will do once the factories

start up again, and shipping improves.

Tags: nomad

Top-plate of lithium powerbox

The plywood floor is 235x225x9mm, with 12x20x1.5mm angle assembled around it, see previous blog post:

https://bkhome.org/news/202004/base-of-lithium-powerbox.html

The top of the powerbox will be a flat surface. This is plywood

measuring 238x228mm (3mm longer on both sides than the base plate). In this case I have used 6mm ply, which will also

be used for the sides. It is just that I have 6mm marine ply in my

garage, and want to make use of it.

I also have some 12x12x1.5mm angle in the garage, so have used that around the edges:

...that is upside-down. Here it is the right-way-up:

The screws are 6G 9mm dome-head, for metal and wood, which meant the

tips stick out the other side of the plywood. However, it was easy to

file the metal tips flat to the surface.

This gives me a completely flat surface on top, on which the DC-DC charger will be mounted, plus two grab-handles.

A practical detail for anyone in the future who might follow these

plans to build their own powerbox: if you cut the pieces of aluminium

angle too short, no problem as they will be hidden by external plywood

cladding.

On the other hand, if a tad too long, a simple way to grind the end is like this:

I used coarse sandpaper, 40-grit. The sandpaper is intended for

sanding wood, but worked OK grinding aluminium -- the grains did not

come off. The trick to doing it is press firmly with the finger closest

to the end, and drag towards you -- pushing away from you does not work

so well.

The top and bottom plates require corner posts. These are angle

pieces riveted on the inside corners. I used 12x12x1.5mm angle, 30mm

long. The rivets are aluminium 3.2x3.2mm (requiring a 3.2mm, or 1/8

inch, drill bit). Here they are installed in all corners:

Another practical detail: I used two "clamping pliers" to hold the

corner posts while drilling. Otherwise, you could use a small block of

wood and g-clamps.

EDIT 2020-05-01: Important design change

After building the powerbox, I found a very big problem, it was very

difficult to access the battery terminals. The fix is to make the

top-plate removable.

Which it isn't as shown in the above photos, as the screws are

underneath, inside the box. So, instead, screw from the top, through the

plywood into the aluminium.

Please see this post, that shows the final box with battery inside:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

The box will then have removable panels on all four sides and the top. The screws used are 8G 15mm button-head timber screws:

The drill bit used is 2mm. The wood screws are able to self-tap into the aluminium.

Placement of the screws needs to be thought about. I placed them 8mm

in from the edges of the plywood, and they need to be placed so as not

to be underneath where the DC-DC charger is proposed to be located.

Also, there are two handles on the top, which will also have screws that

tap into the aluminium.

Tags: nomad

Confusing online voltage drop calculators

I received an email from Gerard, claiming that my voltage-drop

formula is wrong, by a factor of 2. That is, where I calculated 1.11V

drop, Gerard said it should be 2.22V. See this post from a couple of

days ago:

https://bkhome.org/news/202004/cable-sizes-for-battery-camping-system.html

The factor of 2 difference should have been the big hint. I was

confused for awhile, as some online calculators seemed to support what

Gerard claimed. But then we both realised the reason for the

difference...

Most of the online calculators are for AC cable, with ISO sizes, and

use of twin-core. The online calculators require the length of the

actual cable to be entered, not the total "round trip" through each

core. So for my 15m cable from the solar panel, "15" has to be entered

into the online calculator, not "30".

In other words, where it asks for "cable length" it means the length of the twin-core cable, not adding the return path.

Regarding ISO sizes, these are used for electrical building wiring in

Australia and just about everywhere internationally. There is a nice

table here that shows AWG versus ISO sizes:

https://topwiretraveller.com/sizing-automotive-wiring/#3---table-of-common-cable-sizes-

In fact, that page is an excellent read to understand about all of

the different cable sizes -- and in particular how confusing "auto

cable" is:

https://topwiretraveller.com/sizing-automotive-wiring/

...that page has an online calculator, that requires entry of the

length of one core, so in the case of 15m twin-core, enter "30".

Tags: nomad

Base of lithium powerbox

I have constructed the base, or floor, of what is intended to

become a lithium battery power box. See previous post in this new

project:

https://bkhome.org/news/202004/powerbox-fuse-redesign.html

The foundation is a good place to start, as you would build a house.

Having the floor, how the rest will fit in can start to be seen. Here is

the floor, with battery:

...that empty space on the side of the battery is where the

electrical wiring will go, with a side-opening to enable easy access.

Also in that gap, at the front there will be the front-panel sockets and

coulometer LCD display.

There is about 20mm gap at the back-side of the battery, where there

will be some cabling. The externally-mounted circuit-breakers will be

directly behind the battery.

The DC-DC charger sits on top of the box, and grab-handles will also be screwed onto the top of the box.

Here is the detail of the floor of the box:

The floor is a piece of 9mm thick plywood, 235mm along the front,

225mm deep. I painted it, hence the off-white colour. I used marine ply,

but anything will do, even a chopping board from Kmart or BigW.

Though, the chopping board would need to be 9mm thick or more. The

screws are 6G 9mm dome-head metal/wood type, from Bunnings -- I couldn't

find any shorter screws, hence the thickness requirement of the

plywood. Well, actually, 8mm plywood/chopping-board would do, as the

aluminium angle is 1.4mm thick.

The aluminium is unequal-angle, 12x20mm, 1.4mm thick. I cut each

piece 3mm longer than the board, 45 degree cuts using a mitre-board and

hacksaw. Three holes in each for the screws. I pre-drilled holes in the

plywood, so as not to stress the plywood when screwing the screws in --

as they are close to the edge of the plywood.

I bought 20x12x1.4mm angle, 3m length:

https://www.bunnings.com.au/metal-mate-20-x-12-x-1-4mm-3m-aluminium-unequal-angle_p1079496

Also, for later in the project, 3m of 10x10x1.5mm channel:

https://www.bunnings.com.au/metal-mate-10-x-10-x-1-5mm-3m-aluminium-channel_p1079640

Only simple hand tools have been used, which I anticipate will be the case for the entire powerbox.

Tags: nomad

Powerbox fuse redesign

Previous post for new camping powerbox:

https://bkhome.org/news/202004/cable-sizes-for-battery-camping-system.html

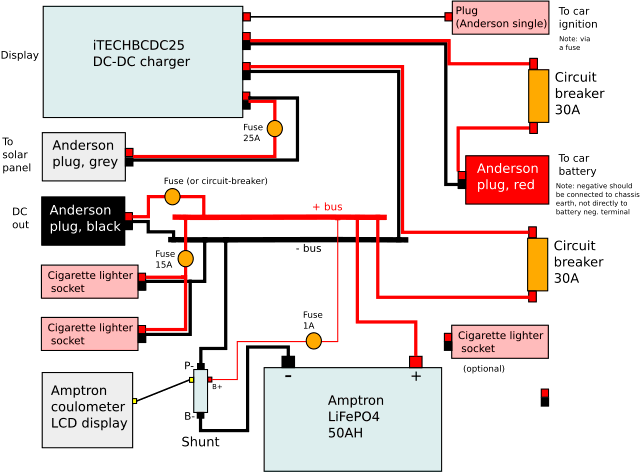

A couple of days ago, created a preliminary circuit diagram, with quasi-physical layout:

https://bkhome.org/news/202004/portable-lithium-power-for-camping.html

After more study of other circuits, I have redesigned with two more fuses:

Previously, if the bottom-right circuit breaker was switched to

open-circuit, while still charging from the car's alternator, it may

have an odd effect on the +bus. Now, that circuit-breaker disconnects

from the +bus, and another fuse has been added to the "DC out" (black

Anderson plug).

It may be overkill, but I also added one to the grey plug, going out to the solar panel.

I also made a note for the red Anderson plug. Modern cars have

"smart" alternators, where there is a shunt between the battery negative

terminal and chassis-earth, just like I have done with the lithium

battery in above diagram.

For the electronic control system of the car to recognise the

existence of the DC-DC charger, the negative lead from the red plug must

go to chassis-earth, preferably close to the car battery.

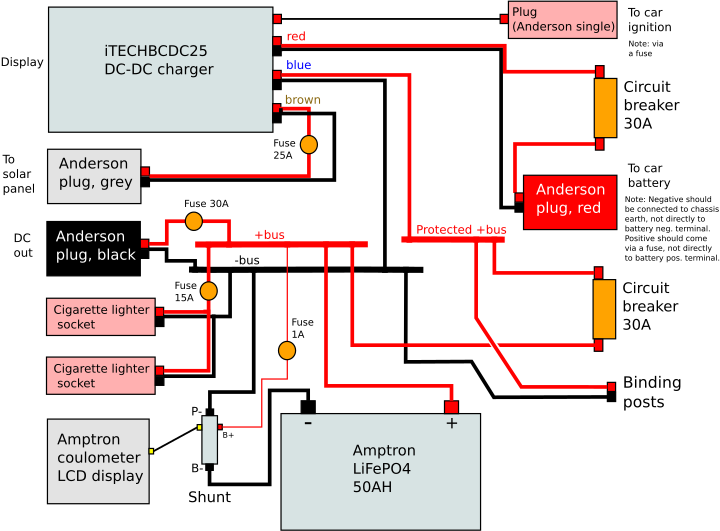

EDIT 2020-05-03:

A "protected +bus" has been added -- the "+bus" is connected directly to

the lithium battery, whereas the "protected +bus" is on the other side

of a 30A circuit breaker. Also, binding posts have been added. Both of

these changes are discussed in a later blog post:

https://bkhome.org/news/202004/dc-dc-charger-issues-and-powerbox-improvements.html

Consequently, the circuit diagram has been updated:

This was created by Dia (a Linux GUI application, available in EasyOS, Quirky, Puppy Linux, and most other Linux distributions). Here is the Dia file:

https://bkhome.org/news/202004/files/powerbox-wiring-diagram3.dia.gz

Here is the file exported to SVG:

https://bkhome.org/news/202004/files/powerbox-wiring-diagram3.svg.gz

Tags: nomad

Cable sizes for battery camping system

This is a continuation of the new project, a portable lithium-battery power system for camping, see the first post here:

https://bkhome.org/news/202004/portable-lithium-power-for-camping.html

It doesn't have to be a lithium battery -- my project can easily be

used with a deep-cycle AGM/GEL battery. The Amptron DC-DC charger that I

am using can handle all types of batteries.

In previous camping trips, I used somewhat undersized electrical

cables. I used a "6mm" automotive twin-core cable, 15m long, from solar

panel to the MPPT battery regulator. From the battery to my tent I used a

Narva "heavy duty" 5m cigarette-lighter extension cable (purchased from

Autobarn).

Thinking about the cable run from solar panel to MPPT regulator. You

need to be careful what the vendor is selling you when they claim "6mm".

6mm automotive cable is slightly less diameter than 10AWG. AWG is the

same as B&S -- these are American wire standards, widely used

internationally, including Australia.

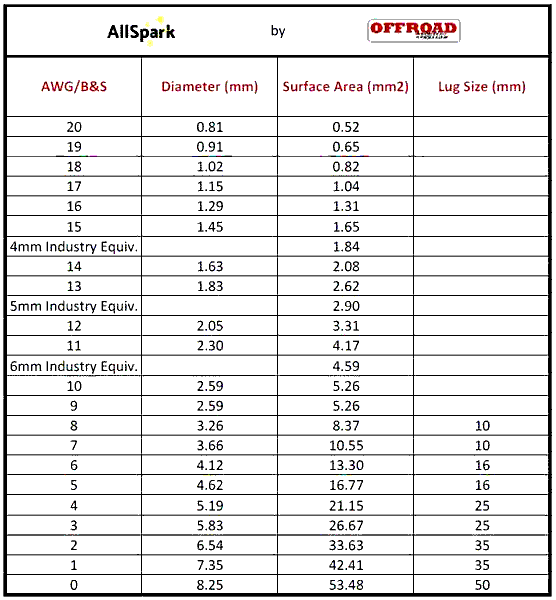

I found a nice table of wire sizes, from here:

The table doesn't have it, but the wire diameter of "6mm" auto cable

is 2.42mm. Those diameters are actual copper wire diameter, not

including the insulation.

The big question is, how much power was I losing in that fairly thin cable? There is a formula:

| Length (m) x Current (A) x 0.017 |

||

| Voltage drop |

= |

|

| Area (mm2) |

...that constant 0.017 is for copper wire.

My 15m cable is 30m round-trip. My "250W" panel was at best only giving about 10A. Plug the values into the formula:

Voltage drop = (30 x 10 x 0.017) / 4.59

= 1.11V

Let's say that the panel is putting out a voltage of 16V, so the power output of the panel is:

Panel power out = 16 x 10

= 160W

And the loss in the cable:

Power loss = 10 x 1.11

= 11.1W

...that is a power loss of 7%

Do I want to throw away that much power? No...

Firstly, I decided on a shorter cable. I used 15m before, as there

was one site where I had to place the panel a long way from my car and

tent. However, can make-do with just 10m.

I purchased 10 metres of 6AWG from Big Al's on eBay. I like Big Al's,

delivery has always been remarkably fast. Though, my purchases were

pre-Covid-19, so I don't know about the current situation.

This is the cable I bought:

https://www.ebay.com.au/itm/124137673594

That is heavy cable! Expensive, but much cheaper than buying it locally. Plugging it into the formula:

Voltage drop = (20 x 10 x 0.017) / 13.30

= 0.255V

So the power loss is 2.55W, which is 1.6% ...ah, much better!

Then there is the 5m cable running from the battery (in the car) into

my tent, to run light, computer, fan ...and maybe even a TV. I have a

fridge, but that stays in the car.

I have not done quantitative measurements yet, but did have a problem

on the last camping trip. I took two laptops, my old power-hungry one,

and a modern baby one. I powered them (one at a time) through a 150W

inverter, and it would cutout when tried to run the old laptop -- this

was because the voltage into the inverter dropped to 11.5V, which causes

the inverter to turn off.

On that occasion, I was also running an LED lamp, and was charging my phone. Sometimes plugged a USB 1TB HDD into the laptop.

So the plan is to upgrade to 8AWG cable, and probably keep the length

of 5m, or maybe a tad longer, say 6m. Will need to do some calculation

of power load and voltage drop first.

Tags: nomad