Portable lithium power for camping

Unable to go camping, but putting home-isolation to good use --

starting a new project, a portable lithium battery box for camping.

My solar water distiller project isn't finished -- I had hoped that

it would be, however, the last prototype did not perform as well as I

expected. Sometime, I intend to modify the last prototype, to see if the

efficiency can be improved. for now though, starting a brand new

project...

I own a Dometic 45AH battery box, with deep-cycle AGM battery. This is lead-acid technology, and has various limitations:

EDIT 2020-05-09: Added item-7 to comparison list

- Should only be discharged to 50%, any more will dramatically shorten the life of the battery.

- The battery must not be left in a partially-discharged state, it must be charged promptly.

- The number of discharge-recharge cycles is about 600-1000 (when discharged to 50%).

- Self-discharge about 2%/month at 20degC, 4%/month at 40degC.

- Lead-acid batteries are very heavy -- a 12V, 100AH AGM battery weighs about 29kg.

- Voltage drops considerably at lower state-of-charge.

- Discharge/recharge cycle 70-85% efficient (15-30% lost as heat).

...they are just the ones that I can think if right now!

If the battery can only be discharged to 50%, that means my 45AH

battery is effectively only 22.5AH. As I go camping infrequently, I need

to be mindful of the self-discharge, and attach a battery charger every

now and again.

Comparing the above items with a LiFePO4 lithium battery:

- Should be discharged no lower than 20%, otherwise life will be shortened.

- OK to leave indefinitely in a partially-charged state.

- The number of discharge-recharge cycles is about 2500 (when discharged to 20% capacity, 80% DoD), and about 5000 cycles when discharged to 50% capacity.

- Self-discharge is about 1-5%/month (I don't have any accurate figures for this).

- A 12V 100AH battery weighs about 11.5kg.

- Voltage stays fairly constant right down to nearly 0% capacity.

- Discharge/recharge cycle 90-92% efficient.

Several years ago I bought a 110AH AGM deep cycle battery, but at

over 30kg I could not lift it. Well, I could, at great risk of putting

my back out. Sometime after that I bought the Dometic 45AH box --mostly

because I could lift it!

So, finally have decided to go over to a lithium system for camping. I

purchased an Amptron 12V 50AH battery -- oh joy, it weigh only 7kg! The

company claims that even if discharged 100% (DoD), that is, down to 0%

capacity, it will still give 2000 cycles -- hmmm. If I discharge it by

80% DoD (down to 20% capacity), that gives me 40AH, almost twice that of

my Dometic battery box.

Here is the company web page for this battery:

https://www.amptron.com.au/12v-50ah-lithium-lifepo4-battery.html

...and immediately you will see a problem: the price. yes, AU$545,

plus postage. For 100AH, you would be looking at around AU$800 - 900.

You can find cheaper on eBay, but beware, they are cheap for a reason.

Anyway, I have been squirrelling-away parts required for this project

over the past several months. Have recently ordered a couple of final

parts off eBay -- coming from the other side of Australia, so may take

awhile. Just about have everything ready to go, sitting here in my

loungeroom, and can now eye-ball it all and visualize how it will fit

together.

What I am proposing is a portable box, that will sit in the front of

my vehicle, where the passenger's legs would normally go -- I am hoping

that there will be enough space for the occasional passenger to place

their legs beside/behind/in-front of it -- whatever.

But it could go anywhere, for example behind the front seats -- you would just need to run longer cables from the car's battery.

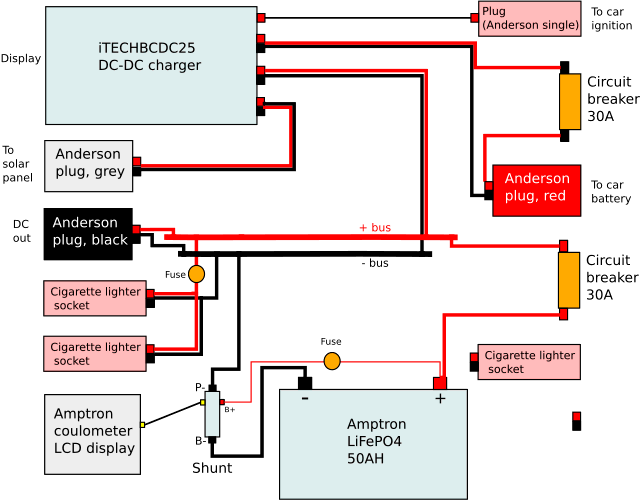

To get the ball rolling for this project, I need a circuit diagram,

but I want one that also indicates the physical layout. I constructed

the diagram in Dia, an app in EasyOS and EasyPup. This is the result, exported to PNG:

Here is the Dia file:

portable-4wd-wiring.dia.gz

Here is the file exported to SVG:

portable-4wd-wiring.svg.gz

EDIT 2020-04-12:

The circuit diagram has been improved, see later post:

https://bkhome.org/news/202004/powerbox-fuse-redesign.html

...more fuses, to make it safer.

A note about Dia: I found it to be adequate. I couldn't see how to

create arbitrary snap-to nodes. There doesn't seem to be any object

rotation. These are features that were in diagramming apps that I used

20 years ago in Windows. Anyway, managed to construct a

reasonable-looking diagram.

The left side of the diagram is the "front", which would be the side

facing the door, so that the readouts can be seen. The right side is the

"back", furthest away from the door.

In a vehicle, you would bring a single-core cable from the ignition

key. This will have 12V on it when the ignition is turned on, and tells

the DC-DC charger that charging will be coming from the car's

alternator.

A twin-core cable will come from the car's battery, to a red Anderson

plug. Both of these can be easily unplugged if it is desired to remove

the battery box from the car.

The circuit breakers are there just-in-case. but probably useful to

turn off if not going camping for awhile -- the DC-DC charger does draw a

small current in standby mode.

The Amptron coulometer LCD display also draws a small standby

current, however I have wired that directly to the battery terminals, as

it needs to be calibrated for the battery, and calibration might be

lost if power is disconnected.

The black Anderson plug on the "front" is DC output, for whatever

purpose required. It can also be used for charging the battery -- I have

an Amptron mains-powered 15A LiFePO4 battery charger, which can plug

into the black Anderson plug -- handy to recharge the battery if it is

not being used for camping, maybe removed from the car.

That's enough for this blog post. I plan to provide more details as

the project progresses, such as where to buy the various components,

design of the box, putting it together, and anything else

required.

Tags: nomad

Distiller basin-type proto-3 test result underwhelming

This has taken me by surprise. I have posted reports on what was

intended to become DIY plans for a solar water distiller. Last post

here:

https://bkhome.org/news/202002/finishing-touches-to-solar-water-distiller.html

...there have been many prototypes, and the latest is "basin-type

prototype-3". Yesterday was a sunny sky, just a few wisps of cloud,

predicted maximum temperature of 32 degC, so I decided to test the

distiller.

I put in 1.5 litres, then used wood shims under the feet to level the

basin -- very easy to do, just make sure the water is spread across the

entire surface. Then added another 2.5 litres.

Here are the measurements during the day:

| Time am/pm |

Amb. degC |

Sun W/m2 |

Top degC |

Back degC |

Comment |

| 9.05 |

24.4 |

850 |

28.3 |

26.2 |

Full sun at 8.15am |

| 10.05 |

25.5 |

940 |

38.9 |

30.2 |

5mm water in bottle |

| 11.05 |

26.7 |

975 |

50.1 |

35.3 |

|

| 12.25 |

28.2 |

980 |

62.1 |

44.2 |

|

| 1.05 |

29.2 |

999 |

65.8 |

44.5 |

|

| 2.15 |

30.6 |

980 |

63.8 |

45.3 |

|

| 3.15 |

30.5 |

930 |

60.6 |

45.5 |

|

| 4.20 |

30.5 |

820 |

51.8 |

41.1 |

Stopped at 6.00pm |

Total collected distilled water: 1.23 litres

That is not as much as expected. See here for comparison:

https://bkhome.org/news/201912/solar-distiller-showdown-take-2.html

And for the record, some further analysis that lead to design of the latest prototype:

https://bkhome.org/news/201912/further-analysis-of-basin-type-distiller-test.html

The current design, with 20 degrees glass slope, has very large

side-walls, and the temperatures measured on the back outside are rather

high. I might construct insulation on the side walls and test again.

Note, those top and back temperature measurements were taken with the IR

meter held about 2 inches away from the surface, about 3/4 the way up

the glass and the back side.

Tags: nomad

Toughening up a 4wd for driving on corrugated roads

Outback dirt roads in Australia are famous for their bone-shaking corrugations. I posted about this awhile back:

https://bkhome.org/news/201907/corrugated-outback-roads.html

I will be upgrading to a 4wd soon, with the intention of being able

to handle these roads, and also to drive on soft sand tracks. So, I read

with interest any experiences and information about toughening-up the

vehicle appropriately.

A few days ago, I came across a Facebook post by Benno. Benno took

off into the Red Centre of Australia in his new Jimny 4wd, driving

10,000km, 2,000km of those on corrugated roads.

Now that is fascinating. I have done a couple hundred km, and it felt

like my car was shaking to bits. Okay, it was only a road car, Holden

Barina, with suspension only designed for smooth roads.

This is Benno's Facebook post:

https://www.facebook.com/groups/1196794093818351/permalink/1534316880066069/

This is a photo Benno posted. The trailer is custom, with tyre-width to match the car, and the original tyres off the Jimny:

Quoting Benno:

The trailer had my bed in it plus battery and charging for the solar panel. Chairs and table and my chemical toilet plus 2 more jerry cans. The trailers tare is about 140kg. I estimate that I pushed it to the 350kg limit with a tow-ball loading of about 40kg. I fitted the tyres I took of the Jimny onto the trailer. The suspension on the Jimny gave up the ghost after 2000km of corrugated road, but I got into Coober Pedy. Found out that TG just released the 40mm lift kit which I had sent the closest installer which was in Alice Springs. Also did my 10k service in Alice Springs. The people in Alice Springs sure know what they do. I can only recommend it. My Jimny is automatic, and if you set it on cruise control, it just goes. Towing the trailer was no issue I would even say that the trailer stabilises the car on corrugated roads. There is always a surprise around the corner, but the Jimny has mastered them all in its stride. From bulldust holes that could have swallowed a truck to cattle grids that had a 10cm step up invisible potholes (more like open-cut mines) to rocks on the road, you would never believe they fit under your car. And whenever you were flying over the corrugation and court yourself thinking, "This is actually not too bad" then this was precisely the point to get ready for the next surprise. But all in all, I would do it again in a heartbeat.

I posted a reply:

When you say that the suspension "gave up the ghost", what actually happened to it?Benno replied:

When you travel over corrugated roads for extended periods, the oil in the shocks heats up, and cavitation can cause the oil to foam, in which case the oil in the shock absorber loses its viscosity and simply stops doing its job. Because of the weight in the back and the tow-ball loading, the shocks collapsed, and I was riding the rubber bumpers. This occurred going around a corner and just given me one more of my unforgettable memories. The back dropped by about 10cm, enough for my trailer chain to hit the road. Suzuki Australia offered to replace the shock, but I decided to upgrade. The original shocks are not built for this kind of work, so if you choose to drive on corrugated roads you probably can do it with very little weight in the back, then I think you will be ok. If you intend to do some overlanding, you have to do some modifications. 1st Tyres, 2nd Bullbar, 3rd Spotlights and shocks. And if you want to put your Jerry cans somewhere, you need a roof rack. After all that you learn to travel light. You know the weight of everything you put into your car. Then comes the point when you simply give up because of all the necessities the better half requires and get a trailer, which I find is the way to go. If you get a trailer, make sure it fits the profile of the Jimny as wind resistance is the most significant factor when travelling. So keep your speed to 100 or less and watch what you put on the roof rack.Fascinating! I am beginning to understand why so many serious 4wd'ers do a lift, of at least 40mm. Superior shock absorbers, with longer travel are put in, and most people also go for fatter tyres.

I also recently posted about live-axle and IFS (Independent Front Suspension) in 4wd's:

https://bkhome.org/news/202001/ifs-versus-live-axle-4wd.html

The "old school" front live-axle is superior if you want to do a

lift. The problem with IFS, as I understand it, is that a lift will

increase the angle of the CV joints, greatly increasing their wear rate.

Then there is the question of legality, and possibly voiding the

vehicle warranty. To find out about legaility in Australia, this is a

great page:

https://www.4wdingaustralia.com/4x4/is-your-4wd-legal/

...that page is written for WA, where I live. Basically, the vehicle

height must be increased no more than 50mm (2 inches). Ah, that explains

something -- many new Jimny owners are going for an ARB or Tough Dog

(TG) 40mm lift kit, with a tyre size of 215/75R15, up from the stock

195/80R15.

The "195" and "215" figures are the tyre width, going to some online

tables, I see that the tyre height is increased from 693mm (27.28

inches) to 704mm (27.7 inches), a difference of 11mm.

That tyre size jump will increase the vehicle height by half of that, in other words, 5.5mm.

So, the ARB or TG 40mm lift, with those 215/75R15 tyres, will

increase the vehicle height by 45.5mm, which is legal. Very

interesting!

EDIT:

Rereading Benno's posts, it seems to me that what actually failed was

the coils. The sudden drop of 4 inches would happen if the coil springs

broke. The Jimny has coil springs front and rear. Certainly if the shock

absorbers were no longer doing their job, or less so, that would have

put enormous stresses onto the coil springs. The effect of the trailer

would be to tend to keep the vehicle body steady, further stressing the

coils. So one thing lead to another.

Which does make me think, a Jimny without a

trailer and not to much weight in the rear, would probably be OK. Well,

Benno did say that.

Tags: nomad

Finishing touches to solar water distiller

Today finished off construction of the latest solar water

distiller, intended to be put together as DIY plans. The previous post

is here:

https://bkhome.org/news/202002/insulation-under-floor-of-water-distiller.html

I am using a piece of 3mm window glass, not low-iron, just ordinary window glass, as used in my tilted-wick prototype:

https://bkhome.org/news/201911/solar-distiller-prototype-4-first-test.html

...that glass is 572x672mm.

The wood frame of the latest distiller is sized such that the glass

only overlaps about 10mm onto the frame, the wood being 19mm thick. I

purchased silicone foam strip for the glass to sit on:

![]()

...I ordered 3 metres of 5x10mm (second from left in above photo), at AU$7.22.

Note that some vendors on eBay have solid silicon strip, but I thought perhaps that would be too firm.

I ran a bead of white silicone sealant around the wood frame, for the

strip to sit on, and placed a MDF sheet on top to hold the strip flat

while the sealant set. Later, ran another bead around the inside, where

the silicone strip meets the wood, so that no water can seep underneath

the strip.

Then there is the question of some kind of brackets to hold the glass

in placed, firmly pressed against the foam strip. There are various

ways that the brackets can be designed, what I did was buy 1 metre of

this, at AU$7.40:

https://www.bunnings.com.au/metal-mate-27-95-x-12-7-x-1-7mm-1m-aluminium-section-sail-track_p1109887

...I marked out 25mm lengths, and holes suitable for inserting 6G

wood screws, then used a hacksaw to cut off the bottom flange, then each

25mm length. Tidied up with a file.

I bought a packet of wood dowels, 38mm long, 10mm diameter, 50 pack.

Prestige brand at Bunnings. Oh, I see, don't seem to be stocked anymore,

but these slightly smaller one should be OK, at AU$2.80:

https://www.bunnings.com.au/prestige-8-x-32mm-timber-joining-dowel-50-pack_p4016508

Um, the "Tools" section of Bunnings does have these, more expensive brand:

https://www.bunnings.com.au/haron-10mm-fluted-dowel-40-pack_p6322822

I cut some of the dowels in half, length-wise, and this is what the final bracket looks like:

...notice that the screw is at a slight angle, not 90 degrees to the wood surface.

And after installing all of the brackets:

Almost finished! Now for the water inlet and outlet...

For the water inlet, I purchased a funnel from Supercheapauto. This

is designed for automative use, and has a removable filter, and an

adaptor for plastic pipe, at AU$9.99:

https://www.supercheapauto.com.au/p/sca-sca-funnel-3-in-1-flexible-spout/291162.html

...it came with a short length of pipe, however, I attached my

silicone tube. The adaptor looked like suited for 9mm plastic pipe, so

what I did was glue a 13mm trickle end-plug onto the adaptor.

I have posted about doing this kind of operation before. It requires

special plastic-bonding glue. I use Selleys All Plastic Fix, at AU$8.35:

https://www.bunnings.com.au/selleys-3ml-all-plastic-fix-primer-and-adhesive_p1230083

And the end-plug is a Holman's brand:

https://www.bunnings.com.au/holman-13mm-poly-barbed-micro-end-plug_p3110069

So that you can see how it is done, see this link:

https://bkhome.org/news/201911/taps-for-basin-type-prototype-2.html

And here it is all in place:

For the water outlet, I just used a cheap 13mm inline tap from Bunnings, at AU$3.97:

https://www.bunnings.com.au/pope-13mm-in-line-barbed-tap_p3129102

Shopping list, prices in AU Dollars:

| Glass, 3mm, 572x672mm |

|

| Silicone foam strip, 5x10mm, 3m |

$7.22 |

| Aluminium sail-track extrusion, 1m |

$7.40 |

| Wood dowels, 8x32mm, 50 pk |

$2.80 |

| Plastic funnel, with pipe adaptor |

$9.99 |

| Plastic bonding glue |

$8.35 |

| End plug, 13mm (Holman) |

$0.80 |

| Inline tap, 13mm, plastic |

$3.97 |

Now I need to wait for a nice sunny day...

Tags: nomad

Insulation under floor of water distiller

The saga continues. Here is the previous post in the gradual

accumulation of what is intended to be DIY plans for a solar water

distiller:

https://bkhome.org/news/202001/construction-of-distilled-water-runoff.html

Now for the insulation under the floor of the basin. I was going to

use fibreglass batts, after misadventure with using expanding foam with

the previous prototype:

https://bkhome.org/news/201911/first-go-at-using-expanding-foam.html

...in that case, I had spread baking paper, which turned out to be a

very bad idea. If I spray the foam directly onto the (slightly damp)

plywood, it will stick and (hopefully) not lift off. So, decided to give

expanding foam another go...

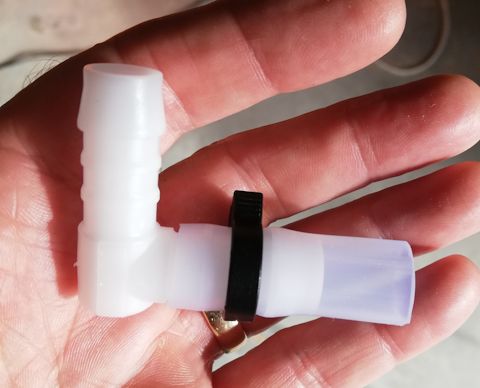

Before we get to putting in the insulation, there is the matter the

inlet and drainage plumbing. Contrary to what you might expect, I put

the inlet as a hole in the floor of the basin, not on the side wall. I

also cut a hole for drainage. These two holes are at opposite sides of

the basin, with the intention that water can be poured into the inlet

and flow out the drainage hole, for periodic flushing of the basin.

Both holes were cut with a 16mm spade drill bit. Silicone tube is

then inserted into the hole and sealed with black silicone sealant. I

want the tube to bend 90 degrees, so I bought two Norma brand 13mm

elbows:

...these are for automotive use, and the plastic will work up to 120

degC. Cost a bit more than trickle irrigation elbows from Bunnings

though, AU$4.97 each.

These are attached to a short length of silicone tube, and I did use a cheap Bunnings trickle-irrigation plastic pipe clamp:

...the silicone tube could probably have been bent 90 degrees without

needing an elbow, without kinking, and maybe with some channel to

prevent it from flattening. Anyway, I went for the Norma elbow.

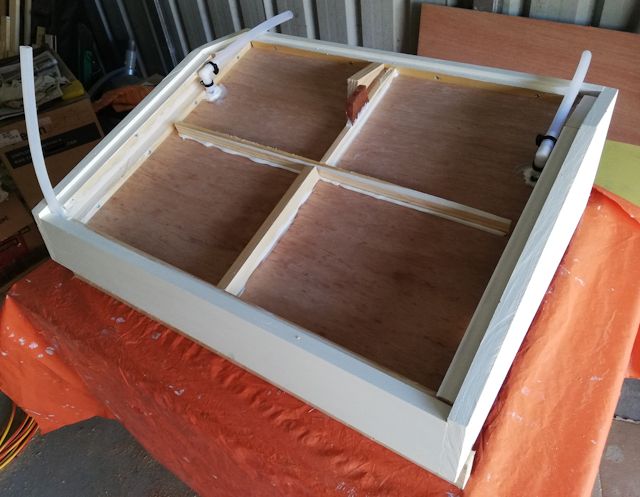

Next, it was glued into the basin floor, here is the underneath view:

...there are some pieces of wood placed to hold it in place while the sealant sets.

Here is the underneath view when both inlet and drainage pipes are fitted:

...notice the two blocks of wood in the top-middle. They are just

some scrap pieces, placed there to give the bottom plywood something to

screw onto.

The bottom plywood is two pieces. I won't give measurements, as it is

easy enough if you build this, to measure and cut the plywood. It is

the same 6mm marine ply that I used for the floor of the basin, cut from

the same original 810x1220mm sheet purchased at Bunnings. Here is what

the two sheets look like when fitted:

...16mm holes were cut for the tubes to stick through, and filed to allow the tubes to come through at an angle.

About those little holes in the above photo. 12mm holes. I had the

idea of screwing on the bottom plywood sheets, then use those holes to

inject the expanding foam.

Ha ha, that stuff has a mind of its own! Yes, I did try that idea,

injected the foam, but it built up enormous pressure, and the plywood

bowed out. I needed to have screwed it down more firmly in the middle. I

had reasoned that the excess would come out of those holes, but that

didn't happen ...perhaps the holes should have been bigger.

Aborted that. Took the plywood sheets off, bought another can of

expanding foam and, the next day, after a spray of water, spread the

foam all over the surface, as best I could anyway. This snapshot is just

after spraying, it did expand some more afterward:

...baking paper was wrapped around the silicone tubes, with sticky

tape, not that I really expected the foam to stick to the silicone tube,

just being paranoid.

Waited another day, then used a large wood saw for most of the

cutting, then a hacksaw blade to finish off, got it reasonably flat:

So, what's next? Obviously, any water placed into the basin is just

going to run straight out of the pipes in the floor. However, the

drainage pipe will have a tap attached and the inlet pipe will bend up

and be attached to a funnel.

This means that there will be water in those pipes, and you might

think that will mean heat loss. However, water is quite a good

insulator, and mostly any heat loss would be due to convection, hot

water rising and thus the water circulating -- which won't happen in

this case, as the hot water is at the top.

Actually, this is an experiment. I will measure the water temperature

where the pipe comes out the bottom of the distiller, very interested

to find out just how much it will heat up.

Shopping list (prices in AU Dollars):

| Norma elbow 13mm x2 |

2x $4.97 |

| 6G 16mm wood screws, 40pk |

$3.98 |

| Expanding foam, 750ml (Bostik) |

$14.85* |

* I used two 500ml cans, however, that was due to a misadventure. A

single can should be OK, and probably it will have to be more than

500ml.

Tags: nomad

First camping trip in 2020

I have been away for about five days, on the South Coast of

Western Australia, at the Benwenerup campground. The South Coast is a

great place to be in the summer, as the weather is mild, quite

changeable actually -- over the days that I was there, a couple of days

it was quite hot, I think mid-30s, a couple of nights were quite cool,

one morning there was a drizzle of rain, most days there was a cool

breeze coming from the south.

Anyway, the campsite. It is run by DPAW:

https://parks.dpaw.wa.gov.au/site/benwenerup-campground

This post is a mini-review of the campsite and the experience of staying there.

I went there just after the school holidays, as these coastal

campsites can get crowded during holidays. There are 14 bays, some

of which are large enough to take a group with 3 or 4 RVs. When I

arrived, only 3 bays were occupied, 2 were caravans and one was a

campervan -- the latter was a young foreign couple, who departed early

the next morning. The other two were elderly couples -- yes, grey

nomads!

I found a nice spot, with adequate shade but still with a nice aspect to get sun for my solar panel:

The cost is $7 per person (concession price, AU dollars), but there

was also a $8 fee to get into the Stokes National Park (again, concession price). I booked in for

five days, and paid the site host, Phil. Phil is another grey nomad, travelling solo.

There are people who volunteer as site-hosts at DPAW campgrounds. In

Phil's case, he decided that he wanted to do something useful in his

retirement, so became a DPAW volunteer. he explained that the site-hosts

only stay for one month at a site, then move on. In his case, he

volunteers on the South Coast during the summer, then heads north in the

winter.

Phil has a caravan, pretty well decked out, with TV dish, solar

power, etc. Ditto for the other grey nomads that I met there. One thing

of note: everyone was very friendly. One caravan left the next day,

leaving just one -- and I met them at the waterfront, fishing.

Which gets to the big question: what do people do there? Very little,

apart from fishing. I chatted with the couple who were fishing, and

they commented that most visitors just stay one night. If they come with

kids, they realise there is not much to entertain the kids, so they

move on.

Yes, there are no walking trails, and the campground is on an inlet,

cutoff from the ocean by a sandbar, and the water is murky-looking:

...what is causing that froth? It was there every day, all along the

shore. One information poster did say that there is some pollution from

farmland. Even though the location is inside Stokes National Park,

tributaries flow from further afield.

I asked the couple, who seemed to know a lot about the place, about

whether I could swim in it. They commented that no one does, kids don't

either. Well, I did, once, but kept my head above water.

The ocean is not far away, but there is no road to it, apparently not

even a 4wd track. There is a "day use area" about 1.7km toward the

ocean from the campsite, that one can drive to, but then the walk to the

ocean, along the edge of the inlet, is about an hour. The couple had

done the walk on an earlier visit.

I did not want to walk one hour each way, just for a swim in the ocean.

First night there, I had a very pleasant surprise -- there is a phone

signal (Telstra), quite a strong one, 3 bars on my phone. Yay, I was

online that night!:

Another pleasant surprise, the next day I discovered the camp

kitchens, two of them. Rainwater and gas barbecue and stove. And, the

gas was free. By stove, I mean just a ring burner -- at one of the camp

kitchens, the flame kept going out due to the strong breeze, but the

other is more sheltered and stayed lit.

The photo shows sink at one end, gas barbecue in the middle, and ring-burner on the right:

This is the first outing for my Coleman 4P Instant-up Dark-room vestibule tent, that I posted about awhile back:

https://bkhome.org/news/201905/coleman-up-4p-gold-series-dark-room-tent.html

...yes, quite satisfactory. "Instant up" is misleading though, as

that only applies to the inner skin. The "dark room" outer fly skin

takes awhile longer to erect, and there are poles for the front

vestibule, and pegs are required ....so really, the time to put it up is

not much less than any other 4-person tent.

I did like the experience of the "dark room". Having windows on both

inner and outer skins gave a lot of flexibility to control the amount of

light entering and ventilation. On the couple of hot days, the feeling

was that it was doing a good job of keeping the interior a bit cooler

than an ordinary tent.

Now for some bad news: my cheap MPPT solar regulator, purchased from

China via eBay, turned out to be a disaster. I posted about it here:

https://bkhome.org/news/201905/mppt-regulator-is-genuine-mppt.html

...yes, unlike some others from China, that profess to be MPPT but

are actually only PWM, this one is genuine MPPT. That is the good news. This

camping trip was the first test in the field. At first, it looked good.

I took the Atem Power "250 watt" solar panel on this trip, with the

panels wired in series, so putting out a nominal 24 volts.

That Atem Power panel is another story, another cheap product from China:

https://bkhome.org/news/201905/measurements-for-three-solar-panels.html

...anyway, 157 watts is OK for this trip, and the panel is very light so easy to lift.

The MPPT regulator takes care to feed the correct voltage and current

into the battery, and at first it was doing a very good job. Lead acid

batteries have 3 stages required to charge them properly. The second

stage, when the battery is about 80% full (if I recall rightly) is a

boost charge at a higher voltage, then it drops down to a lower-voltage

float charge.

That is really bad, and I immediately disconnected the charger. On subsequent days, I only charged the battery for a few hours, while the charging voltage stayed at a reasonable level, so never fully charged it.

Update on that MPPT charger -- do not buy it!

EDIT 2020-04-16:

Rereading this blog post, I see there is something that needs further explanation. A "12v" solar panel actually puts out 16-18v at the peak power point, and 20-22v open-circuit. Thus, wiring two of these panels in series, the open-circuit voltage will be 40-44v. The MPPT regulator must be specified to withstand this voltage. The Chinese MPPT regulator that I used is rated at 50v maximum into the PV input.

So, if the specifications can be believed, it can handle two panels in series. This is an important point, because some of them can't. There is one MPPT regulator I know of that is specified for maximum input voltage of 25v, limiting it to a "12v" panel -- but you can wire panels in parallel, but of course that will increase the current and maybe require heavier-gauge wire.

Anyway, back onto the campsite experience, do I recommend it? Yes, for a very short stay, or longer if you like fishing.

After leaving Benwenerup, I visited Quagi Beach. This is close-by. Drive back to the highway, drive several kilometres toward Esperance, then turn south onto a corrugated road, then drive 10 kilometres -- be warned, it is very corrugated!

Ah, lovely ocean, lovely beach. The campsite has no amenities, only a toilet, no camp kitchen. Cost is $15 per site, no pensioner discount. This is great for a couple or family. Personally, I loved this place. I didn't stay overnight, just long enough for a swim and walk along the beach.

Note also, no phone signal. I think that this is because the Telstra phone signal is beamed along the highway, and Quagi Beach is further away from the highway than Benwenerup. So that avenue of evening entertainment is out -- but then, it is supposed to be a camping experience. I was going to say, people can chat around the campfire at night, but both sites have all-year fire bans.

Here are web pages with info:

https://www.tripadvisor.com.au/Attraction_Review-g495056-d10073252-Reviews-Quagi_Beach-Esperance_Western_Australia.html

http://www.wanowandthen.com/Quagi-Campsite.html

A lot more people camping here! Oh yeah, one more detail: Quagi Beach is surrounded by State Forest, but it is not in Stokes National Park, so you don't get slugged the National Park entry fee!

Tags: nomad

Construction of distilled water runoff

This is the latest instalment of what is intended to become DIY plans for a solar water distiller. This is the previous post:

https://bkhome.org/news/202001/distiller-painting-inside-and-out.html

Now for the distilled water runoff. Water will trickle down the glass

and at the bottom will flow into a channel, which will be on a slope,

at the end of which will be a tube, taking water out to a collection

bottle.

With earlier prototypes, an ongoing problem I had was the reluctance

of the water to flow down the channel and into the tube. Water has

surface tension, causing it to bead and stay where it is, then maybe subject to re-evaporation. To encourage

the water to flow down the channel, it needs sufficient slope, of

sufficient channel width, and sufficient pipe internal diameter.

What I chose for the channel is 10x10mm aluminium channel, 1.5mm

thick, so the internal width is 7mm. from previous experience, I do not

think it should be any narrower than this. Actually, I selected this

channel as I already had it in the garage. I had purchased it from

Bunnings, intended for an earlier prototype:

https://www.bunnings.com.au/metal-mate-10-x-10-x-1-5mm-1m-aluminium-channel_p1079292

I think that there is silicone channel available on eBay, so that would be an alternative.

What I did was cut it so that it can be inserted into the distiller

with maximum slope, and with a bent lip at the bottom end to encourage

runoff into the pipe:

...on the right-end you can see the bent lip, and on the left-end the

side walls have been cut, such that the channel is only 2mm deep at the

very end. I used a very coarse file to rough-up the three outside

surfaces, to optimise adhesion of the sealant. Here it is inserted:

...glued to the side of the distiller with silicone sealant. And

there is one important detail -- the outlet tube has to be put in place

first.

For the outlet tube I used 12x15mm silicone tube. This has internal

diameter 12mm and outside diameter 15mm, so a 1.5mm wall thickness.

Note, I had earlier bought 12x14mm tube from eBay, with 1mm wall

thickness, which is OK but tends to kink very easily. The tube with

1.5mm thickness was purchased from here, AU$13.08 for 2 metres:

![]()

...for anyone building this distiller, 1 metre should be enough.

Of course, the tube has to be glued into the hole in the floor with

silicone sealant, such that no water can seep out on the sides.

Here are some close-ups at each end:

To finish off, a plate has to be glued in front of the channel, to

separate the water that is in the basin. Something fairly rigid is

required, that will not absorb moisture and will tolerate up to 90

degrees C. It might be possible to use sheet silicone, with reinforcing

glued to it, such as this sheeting:

However, I already had something from an earlier experiment. I had

experimented with coating aluminium insect screen with silicone sealant,

as reported here:

https://bkhome.org/news/201911/first-coating-silicone-on-aluminium-mesh.html

...that was a big area, but all that you need is a small strip of

aluminium insect screen, about 50x670mm. I cut a strip off my big

piece, and folded one side to give more rigidity. I also created small

90 degree flanges on each end, to aid with glueing.

I installed it in two steps. Firstly, glued it to the aluminium

channel, with silicone sealant, held in place by a piece of wood, and

allowed to set overnight. Next day, applied black sealant along the

bottom. Here it is:

...the top edge is folded so is fairly rigid. Notice the height is

almost the same as the wood frame -- there will be foam strips stuck on

top, so the glass will sit about 4-5mm above the wood frame -- so there

will be a gap for the water to flow down. Here are close-ups:

There is an air-gap underneath the channel, which will serve as

insulation. Air will of course expand as it heats, and as it is

completely sealed in, it will cause the wall made from aluminium insect

screen to flex. Even at the runoff-end of the channel, I put plenty of

sealant, so there is no air-connection with the outlet tube -- I did not

want moist air getting into that cavity, as it would become a breeding

place for pathogens.

I anticipate the change in air pressure to be OK, but could drill a tiny

breather hole through the wood frame into the cavity, if desired --

think that is over-engineering though.

Shopping list:

| Silicone tube 12x15mm x1m |

AU$7.61 |

| Aluminium channel 10x10mm x1m |

AU$5.50 |

| Aluminium insect screen 760mm x1m |

AU$11.50 |

...or scrounge a small strip of insect screen from somewhere, such as a scrap yard.

Stayed tuned for the next episode!

Tags: nomad

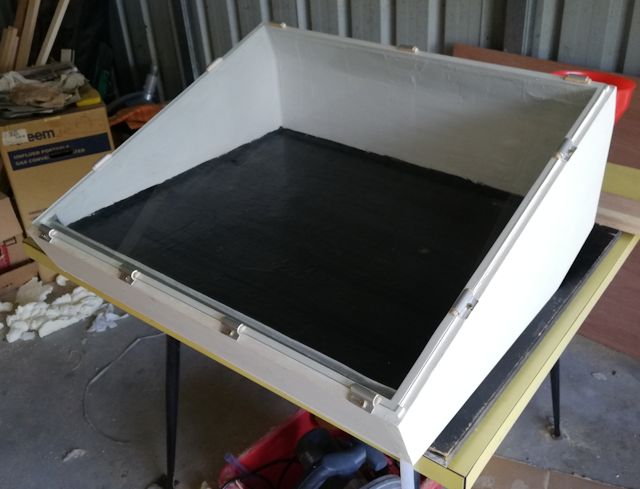

Distiller painting inside and out

What will eventually become DIY plans for building a solar water

distiller has another instalment. Here is the previous post, to follow

the chain of posts:

https://bkhome.org/news/202001/distiller-diy-floor-construction.html

I used slightly-off-white exterior acrylic paint on the outside, two

coats. Did not coat the top edge of the frame, where the glass will sit,

as that will have to be coated with silicone sealant -- and want the

sealant to be spread directly onto the wood, for maximum adhesion.

Note, the paint that I used was just an old tin in my garage. It is

Taubmans Sunproof exterior self-priming acrylic, designed to go directly

onto raw wood, no primer required.

Oh, one thing, I decided to reinforce the plywood floor of the basin.

It is 6mm marine ply, and feels quite rigid, but I had some strips of

pine that had been cut in earlier projects, so decided why not. Here

they are, glued on with silicone sealant:

...with that long piece, I also put three 6G 20mm screws from the

other side, just to be sure the ply won't lift off the wood strip. The

photo also shows the white-painted outside.

To spread the silicone sealant, need to buy sealant of course, and

also spreaders. The sealant is Admil Prosil 10 neutral-cure silicone,

rated as "food safe", and I purchased two white tubes and two black

tubes. I bought them online, from these guys:

https://www.indrub.com.au/prosil-10-100-neutral-silicone-300g-cartridge.html

The manufacturer's site:

https://silicone.com.au/product/prosil-10/

![]()

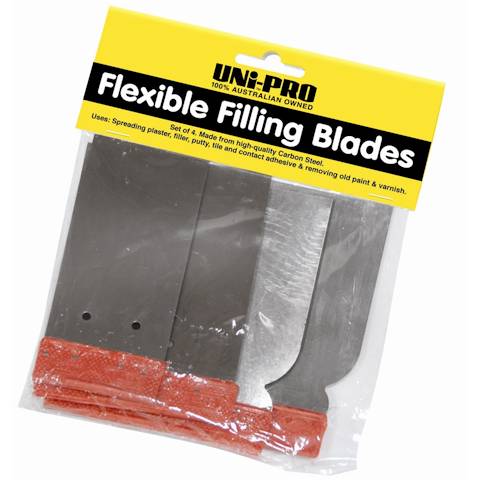

The spreaders were purchased from Bunnings. These flexible steel blades were good for doing the inside sides of the distiller:

https://www.bunnings.com.au/uni-pro-4-piece-filling-blade-set_p1670761

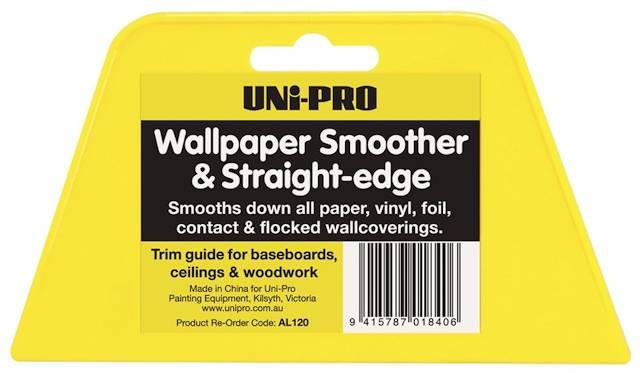

For spreading on the floor of the basin, I used this large plastic flexible spreader:

https://www.bunnings.com.au/uni-pro-wallpaper-smoother-and-straight-edge_p1661659

I used the steel spreaders to spread the white silicone on the walls.

Did it in two goes, firstly just the walls, then the next day did the

top-edges of the frame, and touched up on the walls. Here is a snapshot

after the first coat:

...you can see some thin spots, so it definitely needed going over a second time.

Note: please do wear disposable latex gloves when spreading silicone

sealant, and a well-ventilated room. An old cloth to wipe the spreaders

is also required.

Now for the floor, which will be black. I did this in three goes. Firstly, around the edges:

The next day, spread the rest of the floor. The basic technique is to

zig-zag the sealant thickly over the floor, then drag the spreader,

fairly firmly pressed. On the third day, did another coat to cover some

thin spots. To achieve a fairly thick extrusion as I zigzagged onto the floor (ditto for the first-go, extruded thickly around the edges), the nozzle was cut well down from the tip:

Here is the shopping list:

| Prosil 10 silicone sealant, white, 300g tube |

2x AU$10.62 |

| Prosil 10 silicone sealant, black, 300g tube |

2x AU$10.62 |

| Flexible steel spreading blades, 1 set |

AU$7.32 |

| Large plastic spreader |

AU$2.48 |

The next step will be to construct the distilled water runoff, and holes in the floor for water inlet and outlets.

Tags: nomad