Solar distiller prototype 4 first test

Today, November 7, 2019, in Perth, Western Australia, a sunny

day, mildly warm with prediction of 30 degC, slight breeze in the

morning, wispy clouds, a good day to test the solar water distiller

prototype #4. Previous blog posts have been construction details, last

post:

https://bkhome.org/news/201911/water-distiller-prototype-4-leg-assembly.html

I set it up at 7.35am. It is summer here in the Southern Hemisphere,

and the sun is already quite high in the sky. Some wispy clouds:

As the day progressed, the wispiness became less pronounced, but

there was a slight haze, so the sky was not quite the brilliant blue

that is typical of Aussie summers. Sun intensity quite high though. Here

is the setup:

Despite high hopes for the design of the distilled water runoff, the

runoff slope still is not right and the water didn't want to go into the

outlet tube. That needs more thought, but anyway, did manage to get the

distilled water to come out in one place. There was quite a long time

before any distilled water came out though...

Here is the report on test of prototype #3:

https://bkhome.org/news/201910/first-test-of-water-distiller-prototype-3.html

...which is essentially the same design, just some detail

differences. In that test, it took about 50 minutes for the inlet water

to trickle down the cloth to the bottom. However, in today's test, the

inlet water was connected at 7.35am, and it did not reach the bottom of

the cloth until 8.50am, a duration of 1 hour and 15 minutes. Waste water

started to come out of the outlet pipe at 9.00am.

Why did it take so much longer today, an extra 25 minutes. I think

that is because of lower water head. Although the water tank is the same

height as the previous test, it might seem as though the water head is

the same, however, it isn't. This might seem counter-intuitive, but the

water head depends on how much air is in the pipe from the container tap

down to the trickle flow reducers.

I discovered this problem back when I was designing the flow rate reducers:

https://bkhome.org/news/201906/testing-pope-4-litre-per-hour-dripper.html

For today's test, I didn't bother about getting the air out of the

pipe, and ended up with a slower flow rate. Which has turned out to be a

good thing. Today a very high distiller efficiency was achieved, which

may be due to the water flowing more slowly down the cloth, or maybe

part of the reason.

At 9.08am distilled water started to come out, and I started the measurements from that time.

At 9.30am, sun intensity was 830 W/m2, ambient was 24 degC,

temperature measured with an IR reader, held about three inches away

from the panel, about 3/4 from the top, was 44 degC front and 40 degC

back.

At 10.15, sun 930 W/m2, ambient 24 degC, front 52 degC, back 47 degC.

Note, the panel was oriented at a fixed position right from the start,

estimated to be facing the sun most directly at about 11am.

Ha ha, I have done it again! I went into the city by train, didn't

get back until 1.40pm, and the 450g pickle jar that was left to catch

distilled water had overflowed. Quite a bit, from the puddle. I had only

left a small jar there, as there wasn't much height. Besides, from

previous tests I only expected the jar to be approaching full in that

time duration.

1.40pm, sun 930 W/m2, ambient 27 degC, front 52 degC, back 50 degC.

Note, measuring the IR temperature at the top of the panel, about 2

inches away from the glass, measured 57.6 degC, and right at the bottom,

front, measured 42.7 degC. So, a good differential, ensuring the

circulating airflow.

Moved the panel to better face the sun -- this would probably not happen

in practice, but wanted to make up for the previous unknown water loss.

4.08pm, finished, as shade from patio had just reached the panel. Sun 870 W/m2, ambient 27 degC, front 48 degC, back 44 degC.

By this time, the panel is probably becoming less efficient, due to

loss of air sealing from the outside, as the wood has warped. More about

that below.

Anyway, the collection: 1.1 litres, in 7 hours. That is 157

millilitres/hour. The cloth has a surface area of 0.3327 m2, so to

compare efficiency with the F-Cubed panel which is 1 m2, need to scale

up: 157*(1/0.3327) which is 471.9 ml/hr. The F-Cubed panel gave 563.6

ml/hr, so today's test has a comparable efficiency of 83.7%.

It would actually be higher than that, due to the unknown amount

lost. And the problem of the wood warping. Very good, well on the way to

my survival goal of 1.5 litres per day.

Now the warping problem...

My lack of experience with the properties of wood has caught me out

here. I did think that the wood might swell slightly with the moisture,

but didn't expect that much, and so quickly. I had planned to treat the

wood with mineral oil, however, had not yet done so. I think though, the

oil would probably not have prevented the warping, just slowed it down.

So it was probably a good thing that I have seen the problem so soon.

Here is a photo, taken after 4pm:

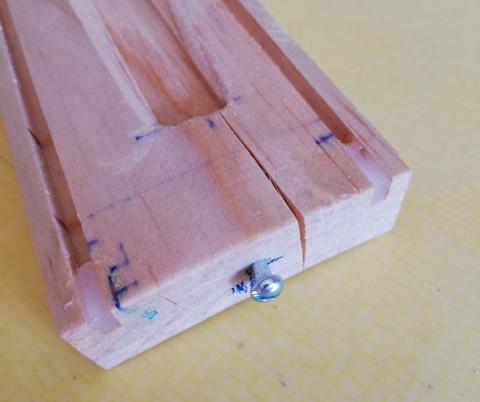

Even worse, it has split:

Right, lesson learned. The design is good, excellent efficiency, with

further improvements in efficiency likely by tweaking type of cloth,

panel angle, type of glass, etc. Note, the glass is cheap "window

glass", which has a slight green tinge, that can be seen when looking at

the edge of the glass. This is due to iron in the glass. There is

low-iron glass available, more expensive. I don't know if it will make

an appreciable difference, but might test replacing the front panel with

low-iron glass.

Anyway, before trying those variations, the frame needs to be

constructed with some other material, perhaps polycarbonate. The

saga continues...

Tags: nomad