First test of water distiller prototype 3

Continuing with reports on construction of solar water distiller prototype #3, here is the previous post:

https://bkhome.org/news/201910/two-inlet-nozzles-works.html

The above link was a redesign of the inlet piping, with two nozzles. I

rebuilt the inlet so now there are two silicone tubes coming into the

distiller:

Today is Thursday, October 17, 2019, Perth, Western Australia. This

morning there was haze in the sky, but still fairly bright sunlight. The

haze persisted all day, however, the light intensity meter gave

reasonably high readings.

I put the distiller together, and had it ready to go about 9.25am. I

oriented the panel to face where I estimated the sun will be about 11am,

and left it fixed at that orientation for the duration of the test. The

panel cloth was dry, and after 10 minutes, this photo shows how far the

water has progressed down the cloth:

The water has actually progressed a bit further than indicated by the mistiness on the glass. After 30 minutes:

...this photo shows the water in the cloth, just a bit further down

than the condensation on the glass. It took about 50 minutes for the

water to reach the bottom of the cloth.

I was messing around with setting up the outlet for the distilled

water. It is a temporary arrangement, with a strip of balsa wood wedged

between the top and bottom glass sheets. Had to fiddle with it to get

the water to come out in one place, but finally placed a cup underneath

at 10.30am.

At 10.30am, still hazy sky, but sun intensity was 840 watts/m2.

Ambient temperature 22°C, front temperature 49°C and back 44°C (IR

thermometer held about 4 inches from glass, about 3/4 way-up the glass).

I was inside the house having lunch, then came out at 12.30 and found

the cup had overflowed. Not sure how much, but the puddle was small.

Anyway, changed the cup.

At 12.30 sun was 790 watts/m2, ambient 24°C, front 51°C, back 44°C.

I kept the experiment going until 2.30pm, when the shade from the

patio had just reached the distiller. Total water collected 500

millilitres, unknown amount lost when cup overflowed. This averages out

to 125ml/hr. Surface area of the cloth is 0.3327m2. To compare with the F-Cubed distiller, which has a 1m2 cloth area, scaling up prototype #3 will be 375.6ml/hr. The F-Cubed gave 563.6ml/hr in this test:

https://bkhome.org/news/201906/testing-f-cubed-carocell-1000-solar-distiller.html

It is only a ball-park comparison, but prototype #2 136ml/hr, cloth

area 0.466m2, and scaling that up to compare with the 1m2 F-Cubed:

291ml/hr. Prototype #2 test is here:

Or putting it another way, if the F-Cubed efficiency is the

reference, "100%", then prototype #3 has 67% efficiency, and #2 has 51%.

An improvement, but not as much as I was hoping for. What is the secret

of the F-Cubed? -- the cloth, the plastic sheeting?

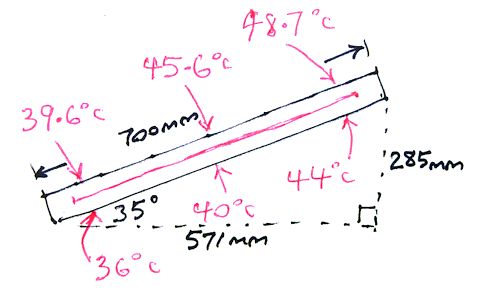

Prototype #3 has the same rotating air principle as used in the

F-Cubed. These are temperature measurements that I took at 1.30pm, IR

detector held about 2 inches from the glass:

...this temperature differential causes the air to rotate. Air flows

down underneath the middle glass sheet, and water condenses on the

bottom sheet of glass. I could see condensation happening, but was

unable to judge how much relative to the top.

My reasoning also, is that the air flow will improve evaporation off

the cloth. One thing I did notice, the front glass sheet remained

clearer, like the F-Cubed -- prototype #2 front glass became very foggy.

This first test has revealed some things that I need to improve in

the construction. Also, need to experiment with different cloth.

Tags: nomad