More planning basin type prototype 2

I posted recently about basin-type prototype #1. There is a link

to testing it here, and notes about white colour for side walls in

proposed prototype #2:

https://bkhome.org/news/201911/white-walls-inside-basin-type-solar-still.html

I have got to the point of starting construction of prototype #2. In

planning, I found this document to be extremely useful:

https://www.appropedia.org/Original:Understanding_Solar_Stills

I posted recently about the Rainmaker 550 basin-type, which claims

60% efficiency. This is the absolute efficiency, of how much of the

sun's energy is actually converted to produce the distilled water (this is

different from some earlier % figures that I posted, that were relative

to the F-Cubed panel).

However, the above link states that the best that can be achieved with a simple basin-type is 43%. Hmmm.

For comparison, the F-Cubed company claim 55% efficiency for their Carocell 1000 (the one that I own).

EDIT 2019-11-24:

The C1000 model is 1x1 metres, but F-Cubed also sell C2000 and C3000, that are the same width, just longer. This gives a longer path for the rotating air, and they claim the bigger ones are more efficient, claimed 65%, with "peak efficiency" up to 80% (whatever that means).

Given how much simpler the basin-type is to build and use, this is now my focus for future prototypes. So what if it is less efficient? -- just build it a bit bigger.

Today I had a chat on the phone with Jim, a retired gentleman who also lives in Perth, and also has an ongoing interest in solar water stills. Many years ago, he built a simple basin type made with stainless steel, and a hinged glass lid for easy access to clean the inside.

Jim is interested in the F-Cubed design, but is put off by all the exotic materials in it, plastic everywhere. After chatting with me, he is also thinking of making his next build a basin type, or some enhanced variant.

As I have mentioned a few times, I want to be able to slide the still vertically into the back of my car, or future car. The basin type has considerable depth, and that is going to take up a lot of space if the still is to be packed in the car along with a lot of camping gear.

Hence, I am going for a very low angle, 10 degrees from horizontal. The appropedia.org link above, explains that sunlight gets reflected off the panel as it moves away from perpendicular to the glass. This is a good page that shows the angle of the sun in Perth, Western Australia:

http://www.see.murdoch.edu.au/resources/info/Tech/house/index.html

...what it says is that if 90 degrees is straight up, the sun will be 81 degrees at midday in mid-summer, and will be 34 degrees from horizontal at midday in mid-winter.

This is telling me that my 10 degree panel should be OK in summer, but will be at best 56 degrees off of perpendicular to the glass in mid-winter -- which is not good.

What I am proposing is a hinged reflective panel, that will be raised in winter. This is hinged along the top side of the panel, and even in summer should provide some efficiency improvement. It will also provide protection to the glass when the panel is transported.

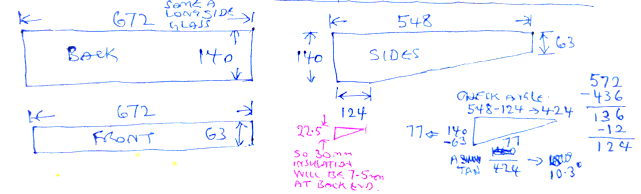

OK, starting the build. I bought 140x12mm dressed pine from Bunnings. This is very thin, but one of the goals of this prototype is to make the weight as low as possible. I am re-using a piece of glass that was used in the sloping-type prototype #2, 672x572mm, 4mm thick. A sketch of the wood pieces:

For an angle of 10 degrees, the back side of the panel should be

162mm, but I have used 140mm wide pine. Hence the 124mm indent that you

see in the above sketch.

The two triangles that I have cut off the side pieces, could be used to make the back 162mm, if I wish.

The plan is for 30mm thick insulation in the base of the basin, and I

am investigating using a spray can of expanding foam. But that is a

story for the future...

Tags: nomad