Milo Stove: drilling the lid

This is post #4 of the Milo Stove project. Post #3 is here:

https://bkhome.org/news/202308/milo-stove-chicken-tin-and-mesh-stand.html

The lid of the Milo tin is being re-purposed as the base on which will sit the alcohol burner. As mentioned in post #3, the air inlet is underneath the chicken-tin. Here are the holes drilled in the lid:

The air-inlet holes are nominally 9mm diameter, though I was a

bit cautious and they are actually more like 8mm.

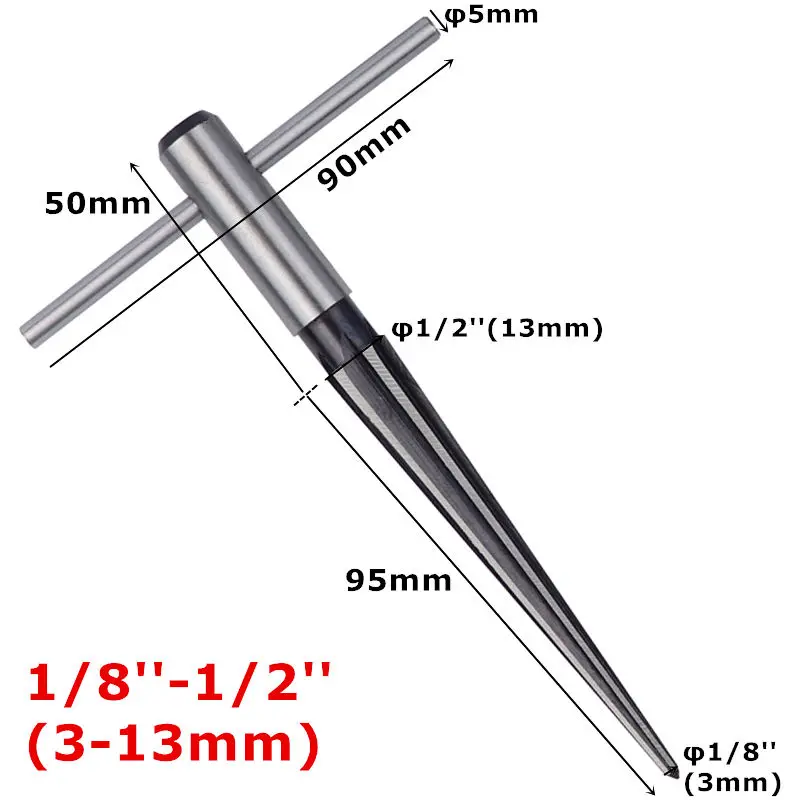

Cutting 8-9mm holes in thin tin is tricky with a hand tool, so I first drilled 2mm, then 5mm, then reamed it out and a final touchup with a round file. My reamer is a hand tool; they are readily available, look like this:

After drilling all the holes, here is what the 30ml Speedster burner looks like when placed on the lid:

The chicken-tin goes over that, held in place by pieces of aluminium rod riveted on three sides:

...have not yet drilled the 25mm hole in the top of the chicken-tin.

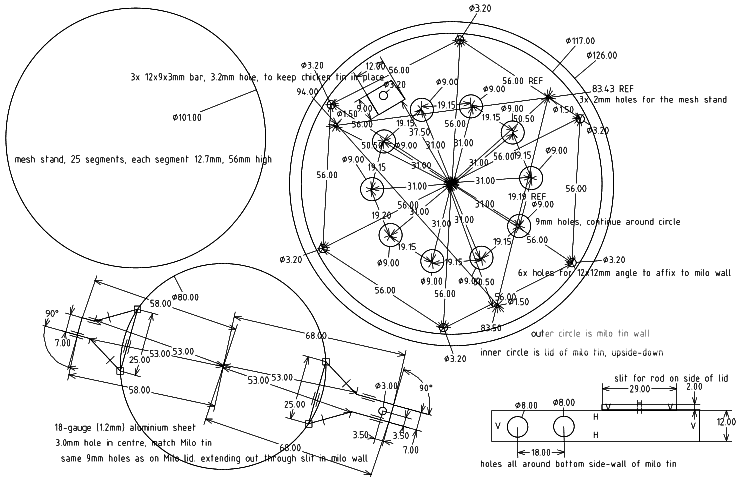

The construction plan was created in SolveSpace. Here it is exported to PNG:

As the diagram shows, there will be a circular piece of aluminium underneath the Milo-lid, that can be rotated to adjust air intake.

As you might glean from looking at the diagram, the Milo lid is

about 12mm above the bottom of the tin, with 8mm holes right

around the bottom-side of the Milo tin. Note also, the Milo tin is

being used upside-down.

Of course, this design is an experiment and it will be great if

it performs well, but not guaranteed. If anyone thinks that this

idea for throttling air intake is patentable, I state right now

that the Milo Stove design is public domain. I don't see anything

patentable about it; however, patent law in some countries,

particularly the USA, is so broken that even the most trivial

innovation can be patented.

Tags: light