Tyre scrubbing on trike with suspension

Continuing the custom tadpole trike project, with solar panels and leaning front suspension. Previous blog post:

https://bkhome.org/news/202310/design-of-front-suspension-for-leaning-recumbent-trike.html

...in that post, there is a link to a video with an animation of a leaning trike design. Here it is again:

https://www.youtube.com/watch?v=c3a0sSPOhb0

...watch just the first 20 seconds, and notice what happens when both

wheels are equally deflected. That is, weight has been applied downward

so both wheels are moved vertically by an equal amount. Notice the

distance between the tyres on the ground: they move inward, toward each

other.

This sideways movement of the tyres on the road surface is known as

"scrubbing". It happens in a car when you corner hard; the tyres scrape

sideways on the road. Ripping off tread.

It is not just when cornering; most suspension designs exhibit

scrubbing when the wheels hit a bump in the road. I want to optimise my

custom trike to handle corrugated gravel roads, in which both wheels hit

the same bump and get deflected upwards equally. The situation as shown

in the above video.

There are photos of corrugated roads in rural Australia posted to this blog. Here is another, taken at Cape York (photo from here):

...I chose this photo as it is representative of most corrugated

roads; fairly "mild" ripples, but still car-destroying. Here is an

example of more extreme ripples (photo from here):

...these roads will quickly erase the tread on the tyres for the

suspension design in the above video. I have looked at other trike front

suspension designs (leaning and non-leaning) and they all have this

scrubbing effect. The ones that I have seen anyway, though mostly I have

studied personal projects, not commercially manufactured trikes.

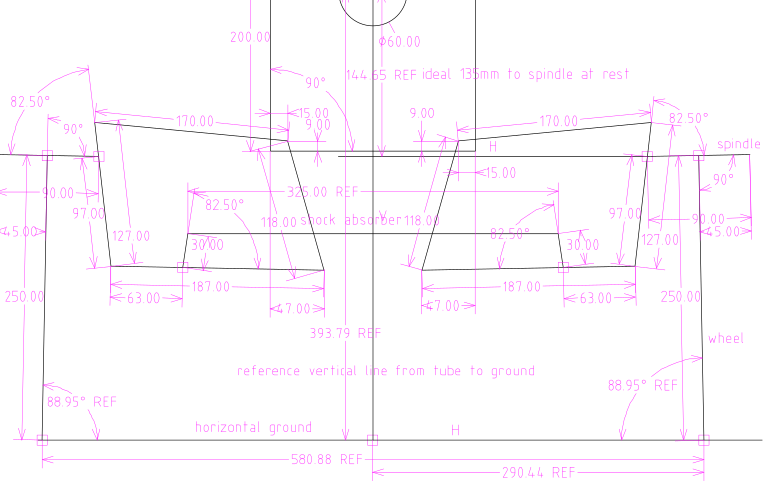

My trike design has double-wishbones, very short length. There is

going to be scrubbing. The focus is on minimizing it for the particular

situation of corrugated roads. Here is the latest SolveSpace design:

...riding on a corrugated road, the wheels hit a ripple and get

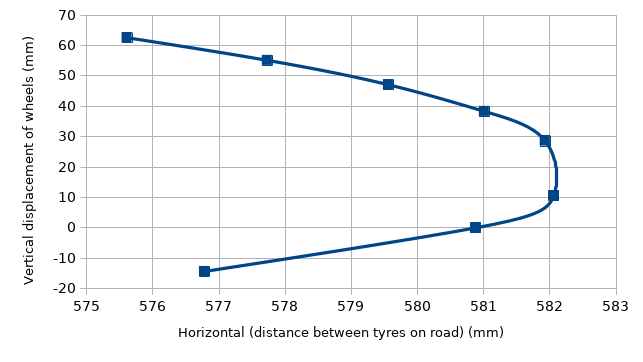

deflected upward. Using SolveSpace, I plotted values, vertical

deflection of the wheels against scrubbing on the road surface:

...the "0" on the vertical axis represents the rest point; riding along

on a smooth road surface. Hit a ripple and the wheels deflect upward. A

vertical deflection of 10mm causes just over 1mm scrubbing (the

horizontal axis). 40mm vertical deflection and scrubbing is back to

almost zero. 60mm (2.4 inches) vertical deflection and the tyres on the road surface

will have scrubbed inward (toward each other) about 5mm; that's about

2.5mm on each tyre.

After a lot of playing with SolveSpace, that seems optimum. It is a

compromise. It might even be negligible. I optimized for 40mm (1.6 inches)

vertical travel, the tyres will wobble about 1mm outward then 1mm

inward (0.5mm on each tyre). As deflection increases, camber will increase negatively (top of

wheels moving inward), and will probably run a fairly low tyre pressure

on those roads, both of which may lessen the effect of the scrubbing.

So, my reasoning is that 0.5mm per-tyre either way is negligible.

Note, I am deliberately limiting the vertical travel to 50-60mm

maximum, so no cushioning for bigger bumps. There are issues with

steering linkages; maybe trouble if too much vertical travel,

particularly with the tie-rods and toe setting.

I'm a suspension neophyte, so the above is just my

beginner's reasoning. We shall see. Get it wrong, and the tyre tread

will get worn out very quickly.

Tags: light