Construction of front axles for custom trike

Continuing the full-suspension tadpole trike custom project. Previous blog post:

https://bkhome.org/news/202311/beware-cheap-drill-bits.html

Earlier in the project, I purchased this go-kart front suspension kit:

https://www.aliexpress.com/item/1005005943611409.html

...shipping cost was high. Shipping from China is higher than it used to be, pre-pandemic. One comment: having gained more experience with bicycle components and general metalwork, if starting from scratch now, would be tempted to manufacture it myself. Another comment: it is cheaply made, sloppy "bearings".

There is a problem with that kit; the wheel axles are 15mm

diameter. However, my trike front wheels require 20mm

through-axles. The through-axle for bicycle wheels can be 10mm,

12mm, 15mm, up to 20mm for premium mountain bike.

Another problem; the axles do not have brackets for disk brakes. So, I bought these; 17mm diameter shaft and with disk brake mounting brackets:

https://www.aliexpress.com/item/1005003033562914.html

These axles have two problems; 17mm diameter, whereas I need 20mm, and the shaft is stepped, up to 19mm near the disk-brake mounting bracket. So, I machined it down to 17mm, as close to the disk-brake bracket as possible:

...after taking that photo, put it back in the lathe and machined an extra couple of millimeters...

The diameter of the axle was brought up to 20mm by a sleeve; an aluminium tube, of 17mm ID and 20mm OD, bought from here:

https://www.aliexpress.com/item/1005004347889082.html

There was yet another problem; the shaft was not quite long enough, so as to be able to screw the nut onto the threaded end far enough to insert a split pin. Fortunately, I found "concave washers" and bought the M10x40x1 size:

https://www.aliexpress.com/item/1005005527446669.html

This photo shows the entire assembly:

...the copper washer is M17x30x2, from here:

https://www.aliexpress.com/item/1005003020060256.html

The concave-washer has a 10mm hole, so had to drill it out to 14mm. That was a challenge, as the work-piece has to be held firmly. I may have gone a bit overboard in that regard; it is certainly held firmly...

...I moved the workpiece slightly and increased the hole diameter to about 15mm.

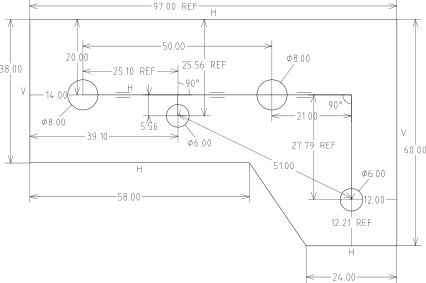

Next job, constructed adaptor-brackets to hold the brake calipers. Used some 3mm thick aluminium plate, it is type 6061 or 7075, not sure which, these dimensions:

The SolveSpace file, with false ".gz" appended, is here.

The adaptor plates drilled and cut-out:

Assembled:

...will replace those long M8 bolts with shorter ones, and use lock-nuts.

There are some finishing-off details to do.

For example, the 20mm OD aluminium sleeve and 17mm steel shaft are different metals, that will cause corrosion of the aluminium and rusting of the steel when wet. The intention is to smear epoxy resin around the steel shaft and slide the aluminium sleeve over it, providing a barrier. Will also use thin silicone washers as water barriers each end of the axle.

The aluminium adaptor-plate will be painted, probably black.

Going slowly, but it is a fun project. More challenges ahead, and some details not yet worked out. Now for something completely different; photo of a beach visited recently...

...those dots in the water are people. Mid-summer here in Australia.

EDIT 20231227:

I bought the complete go-kart suspension kit, as shown in the

first photo above, then replaced some items, such as the

steering-knuckles and shock-absorbers. So, if you are interested

in building a front suspension similar to mine, the

suspension-kit can be purchased in parts.

For example, the wishbones/swing-arms can be purchased alone:

https://www.aliexpress.com/item/4000056825228.html

Regarding the steering-knuckles, there are alternative designs, such as this:

https://www.aliexpress.com/item/1005004116654463.html

...the above has a 17mm diameter axle, but I see also there are

steering-knuckles available with 20mm axle.

Tags: light