Prototype 4 warped wood has unwarped

Fascinating! I posted about first test of solar water distiller protototype #4 two days ago:

https://bkhome.org/news/201911/solar-distiller-prototype-4-first-test.html

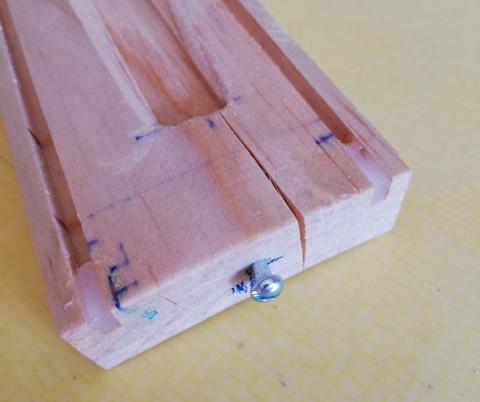

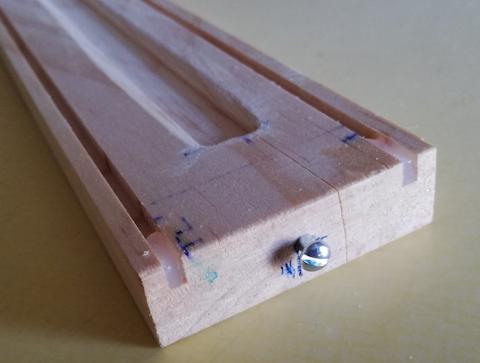

And the wood warped and split:

Most curiously, there was no noticeable warping or splitting when

testing prototype #3, which was essentially the same design. I think

what happened in the last test, it was longer duration, higher ambient

temperature, and when the wood started to split, that allowed water

ingress which accelerated the warping.

It was the top piece of wood that had warped the worst. This would be the hottest part of the distiller.

After the test, I pulled it apart to dry out, and the big surprise this morning:

...the wood has returned to normal shape, and the crack closed.

I received some advise from David ('wdt' in the forum), on a method to preserve wood:

Wood that is well impregnated with wax, is waterproof,

will last almost forever, very stable

Melt wax, no water in bottom (normal for protection,<100)

Wax to 115-125C, do not leave unattended with heat on

Wood in for at least 10 min or longer

Problem is pot, something large enough

Large truck exhaust pipe? up to 3.5", flatten slightly

Sand or file one end 1/4", flatten, crimp in vise, solder with acid flux

OR split with slitting cut-off wheel, solder ends on both

Will not be able to glue ever

More convenient if you can do 2 pieces at once

Careful not to burn, maybe small nail 1/2way in, string

Obviously as you add wood it will cool wax as it boils water out of wood, will also carry the air entrained in wood.

For best impregnation, let it cool in wax until start of solidification, then heat for adequate drainage

Let drip over WET newspaper for easiest clean-up

...looks like an excellent method! However, I have already painted

the wood with mineral oil. Mineral oil is food-safe, can be ingested as a

laxative, or used as a skin softener. It is describe in Wikipedia:

https://en.wikipedia.org/wiki/Mineral_oil

The problem is to find it without additives. Pharmacies in Australia

sell it as liquid paraffin, though one has to be careful about that word

"paraffin" -- there may be other products in hardware stores with that

name, that are not mineral oil.

I bought a bottle of Gold Cross liquid paraffin from a local pharmacy. This is 100% pure mineral oil. The 200ml bottle cost AU$6.95. I am sure that it could be obtained cheaper, but was not sure about the products on offer at Bunnings. Anyway, don't need much.

Unlike wdt's solution, I think that the mineral oil is not a permanent fix. The wood will need periodic recoating.

There is also the problem of the cracks in the wood. After two coats

of mineral oil, I might smear the surface where the cracks are, with

silicone sealant.

Another thing to bare in mind when considering how to treat the wood,

is that the internal temperature of the distiller can get up to about

65 degC (149 degF). This can melt and leach out some treatments. I have

read this 65 degC figure in online reports, for inclined wicking-type

distillers, but maybe could get even higher -- I have yet to test in

ambient 40+ degC heatwave!

Changing the subject, I have started to build a basic basin-type

distiller, using parts from prototype #2. It is going to be extremely

interesting to setup three distillers alongside each other, the

prototype #4, F-Cubed Carocell 1000, and the simple basin-type.

Tags: nomad