Simple basin solar distiller design notes

A few days ago, I posted about the Rainmaker 550 single-slope simple-basin type of solar water distiller:

https://bkhome.org/news/201911/rainmaker-550-solar-water-distiller.html

...for which the manufacturer claimed remarkably high distilled water

output. I want to find out for myself, so decided to build one, no, at

least two.

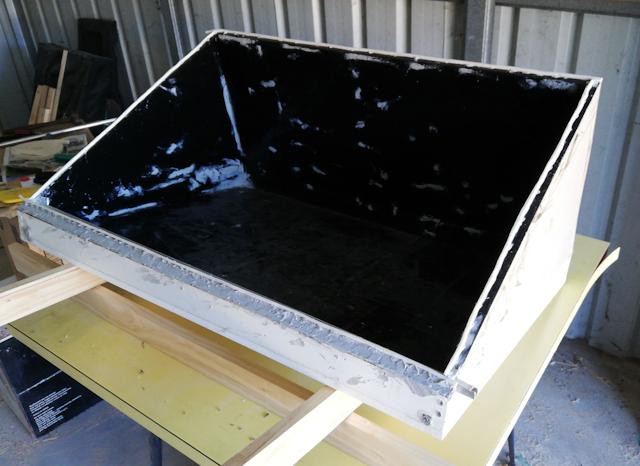

I re-purposed prototype #2, which was the trickle-down type, just one

sheet of glass, and the frame was MDF. The interior was coated with

silicone sealant. That was built back in June:

https://bkhome.org/news/201906/diy-solar-water-distiller.html

...took those legs off, and it then became the water basin. Cut some

more pieces of MDF, and coated the inside with black silicone sealant,

then a bit more patching with some leftover grey sealant:

...also stuck some foam silicone strips on top, and the glass

(600x900mm) will just sit on top. Used a length of 10x10mm aluminium

channel as the distilled water runoff.

I used cheap Parfix brand black sealant, two 310 gram tubes, used it

all, hence resorted to the grey sealant for final patching.

For the record, black silicone sealant rated as "food grade" and

"potable water" safe, is Silastic 732, available at a very reasonable

price from Autobarn (Australia), AU$18.99:

https://www.autobarn.com.au/silastic-732-black-cartridge-310g

The build so far is good enough for basic ball-park testing I

suppose, however, there are two things "wrong" with this design -- let's

call it prototype #1 of the simple-basin design.

Firstly, there is going to be too much heat loss. This design needs

insulation, and I might just stick cardboard onto the sides and bottom

of the MDF.

Secondly, the glass angle is 35 degrees, however, after some more

reading, I found a recommendation that the optimum angle is 15 degrees.

This information comes from here:

https://www.appropedia.org/Improving_Basin_Solar_Stills

...which has a link to this PDF which is where the 15 degrees figure came from:

https://www.ircwash.org/resources/solar-powered-desalination-case-study-botswana

Another recommendation is that the water depth in the basin be kept low, like about 10mm. Can do.

I could cut a slice out of it to lower the angle, but might just leave it as-is, the after some testing, move onto prototype-2.

For basin-prototype-2, might investigate a better insulating

material. I am thinking of black corflute, such as Tunnelcore, from

Bunnings:

...corflute is made with polypropylene, and Tunnelcore has UV

resistance. Polypropylene is one of those slippery kind of plastics that

is very difficult to glue. I am planning to experiment with

heat-gluing.

Tags: nomad