Updated maximum width of bicycle/tricycle in WA

Western Australia has an archaic law that a bicycle/tricycle may be no more than 660mm wide. Our Minister of Transport, Rita Saffioti, was approached by NDIS (National Disability Insurance Scheme), informing her that their mobility vehicles are wider than that. Ms Saffioti responded that she would "look into it". That was mid-2021.

I haven't read anything about that width limit being changed, until today, read this:

...800mm! That's nice, but has it actually happened? That article was posted in June 2022.

So, I searched, but cannot find anything about the limit being increased to 800mm. But, did find this, published November 7, 2023, about "eRideables":

https://www.wa.gov.au/organisation/road-safety-commission/erideables

...maximum width 700mm. But pedal ebikes, motorized wheelchair and mobility scooters are explicitly stated to not be eRideables.

So, do not know if or when this 800mm limit will come into effect. The trike I purchased from China, that I am customizing, is 870mm wide, so would be illegal even if the limit is increased to 800mm.

I would like to keep the trike inside, and my front door is 750mm wide. The current front-suspension design is 660mm wdie, so should I increase that to 750mm in anticipation of the law being changed? Hmmm, what a politician says and what actually happens is another thing. So no, will stay with 660mm. Of course, the wider it is, the less need for a leaning design.

Have just now stumbled upon this:

Quoting:

The Insurance Commission of WA – a state body which last year

paid $29 million to cyclists “for treatment, care and support

for injuries sustained in a crash involving a registered

vehicle” – told CyclingTips that “the specifications of the

bicycle used, is not considered in confirming that right to

claim.”

...that is very interesting. But as the article points out,

private insurance companies are very different, looking for any

loophole to get out of paying.

Tags: light

Two-shock design with swinging steering linkage

Continuing the design of two shock absorbers in the front suspension of a custom leaning trike. Here are the previous two posts:

- Two-shock design with curved rod — November 18, 2023

- Solar leaning trike safety concerns — November 17, 2023

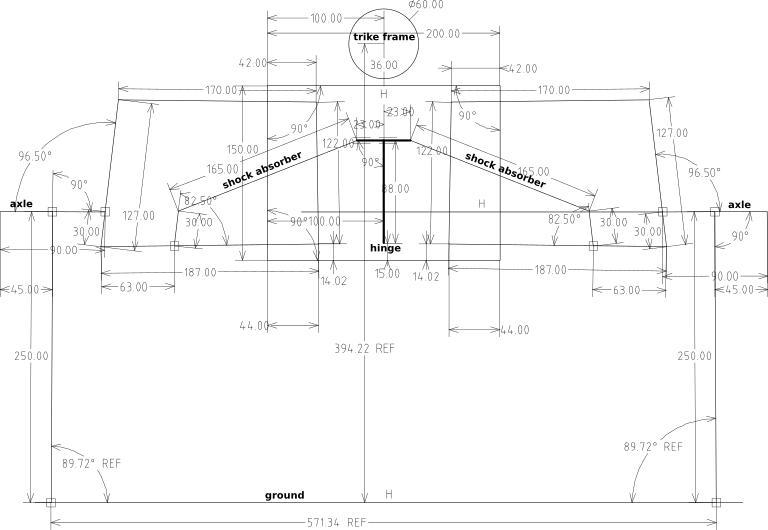

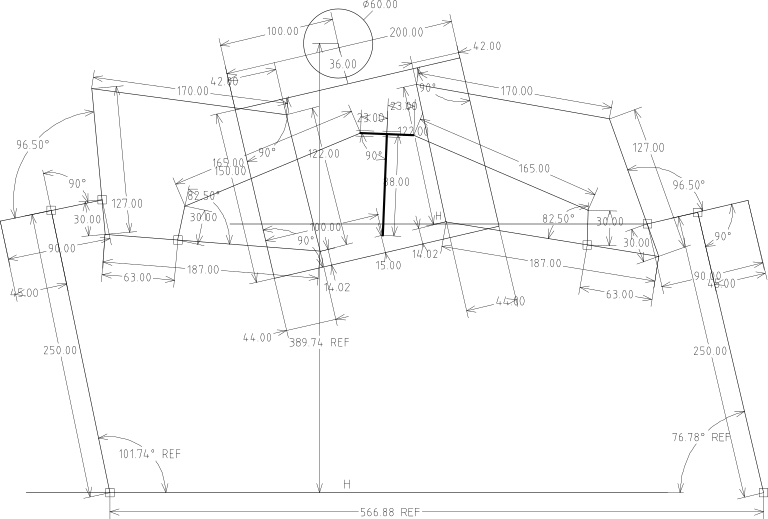

The idea behind the curved-rod is for the steering to tend to go naturally back to driving straight, without any lean. The same effect can be achieved by a swinging linkage, like this:

...it is a T-shape, hinged at the bottom. It would be linked (somehow) to the steering, so turning to the side will swivel on the hinge, like this:

...the natural tendency will be to return to driving straight.

As far as handling road bumps, it will handle up to 75mm (3 inch) bumps.

I had rejected this design before, due to potential kickback into the steering mechanism. However, that can be mitigated by a dampener and some flexibility in the steering linkages. Of course, those country roads that I have previously posted photos of, where both wheels will hit the same ripple, the kickbacks will cancel out.

Here is the latest SolveSpace file (with false ".gz" appended):

This design has one big advantage compared with the curved-rod;

it is simpler and easier to build.

Tags: light

Two-shock design with curved rod

This post is a continuation of the previous post:

https://bkhome.org/news/202311/solar-leaning-trike-safety-concerns.html

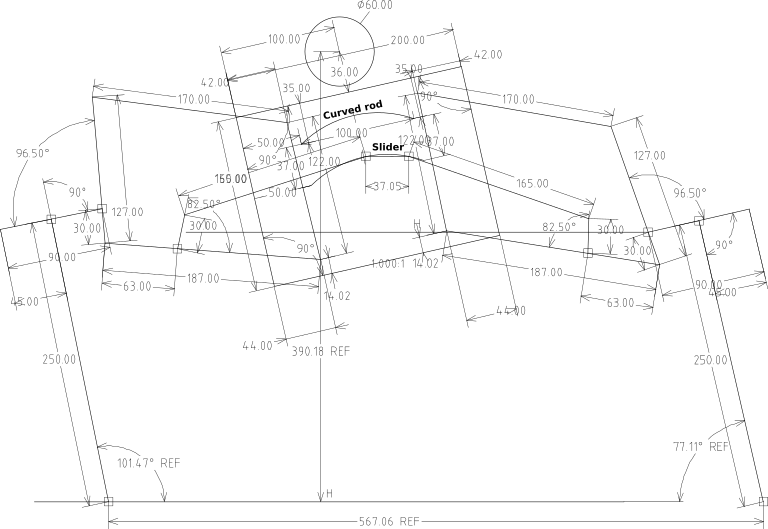

It looks like there is a problem with slider on a straight rod; when lean to the side, there will be a tendency to pull more to the side. This will require more effort to ride in a straight line, as there may be a tendency to pull to the side.

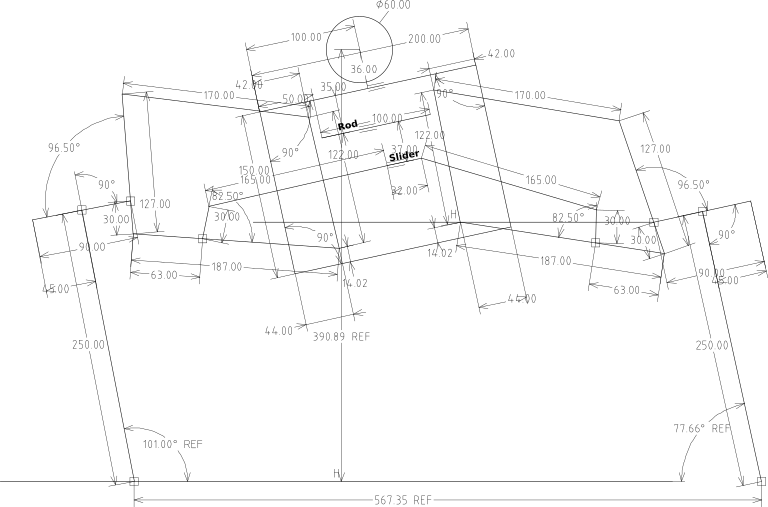

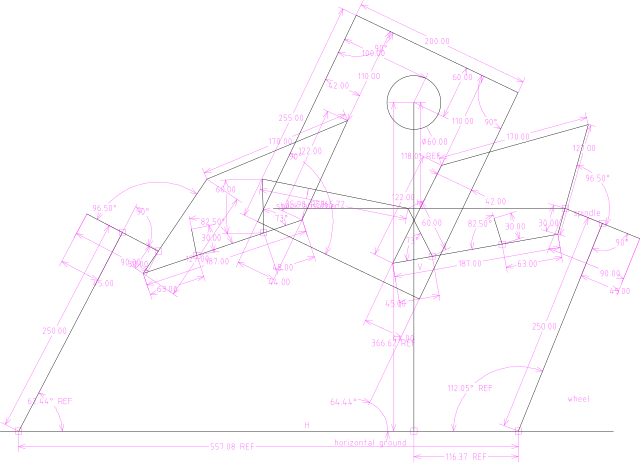

This is a variation, with curved rod. If I have been able to get my head around how this will work in practice, it looks like the curved rod will correct for the rendency to pull to the side. Here it is with the slider pushed so that the trike is leaning:

...the drawing looks like it has two rods. The bottom one is just a path for SolveSpace, for the slider to move along.

Here are the SolveSpace files, first with straight rod, second with curved rod (with false ".gz" appended):

...note, if you want to experiment with pushing the slider, you

will need to delete the "H" that can be seen just above the rod.

That is a horizontal constraint.

I have another variation of the design in mind, will post about that soon.

EDIT:

Here is the next variation:

https://bkhome.org/news/202311/two-shock-design-with-swinging-steering-linkage.html

Tags: light

Solar leaning trike safety concerns

I have been discussing with Bart via email, safety concerns for a leaning trike with large solar panel on top. Some quotes from Bart:

when pivoting around and when going to the max., that the momentum of the top weight will kick your back wheel away. Then you end up with the bike on top and you trapped underneath it....

Your solar panel is not a big sail in the wind when it is turned flat. But that's a real problem when turning that panel sideways by leaning the bike.

...

Turning TOO much and you collapse under the own weight. .... one way or another: Getting a blast from the wind and you lie on the OUTSIDE the corner.

Yes, the momentum of weight up high is an issue. It is important that be minimized and the weight be as low as possible; preferably most below the axis of the wheels.

The wind, now that's a big concern. Lots of guys have added solar panels on top of bicycles, such as this one (image copied from here):

...in windy conditions, an accident waiting to happen!

A recumbent bicycle with weight lower down may be an improvement, like this one (image copied from here):

...but on the otherhand, the recumbent position maybe means reduced ability to lean into a corner and retain balance. And of course, once the rider does lean, the solar panels become a sail.

A non-leaning trike keeps the solar panels horizontal, so less likely to behave as a sail. A leaning trike that relies totally on the rider's balance, is just like a bicycle; at the mercy of wind catching the tilted solar panels.

The earlier blog post described a leaning trike design with a single shock absorber. The advantage is simplicity; however, the downside is it relies totally on the rider's balance. The single-shock design is here:

https://bkhome.org/news/202310/leaning-trike-single-shock-suspension-revisited.html

...it may be possible to introduce linkages from the steering to control the lean, but I have not discovered any practical way of doing it.

So, have returned to thinking about using two shock absorbers. The major advantages of this is that it can be locked to become a non-leaning trike if desired, and lean is controlled by linkage from the steering handles.

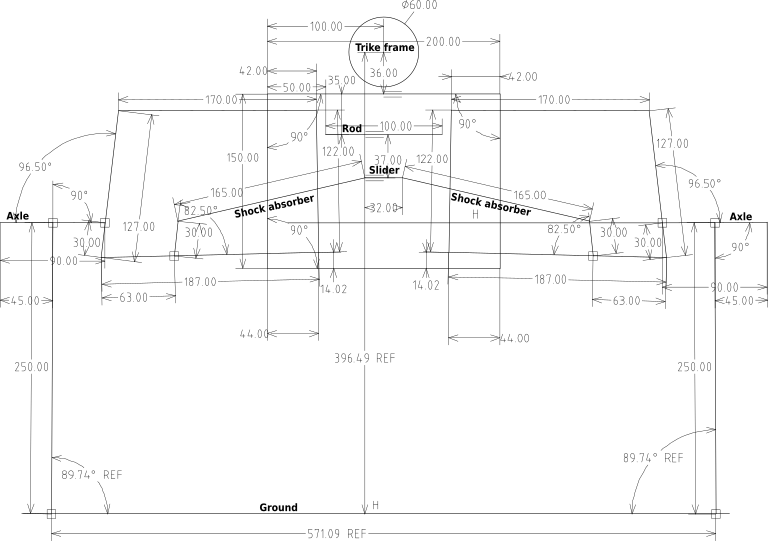

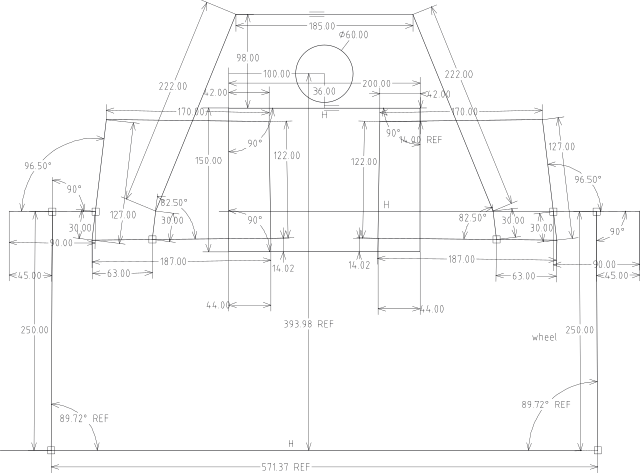

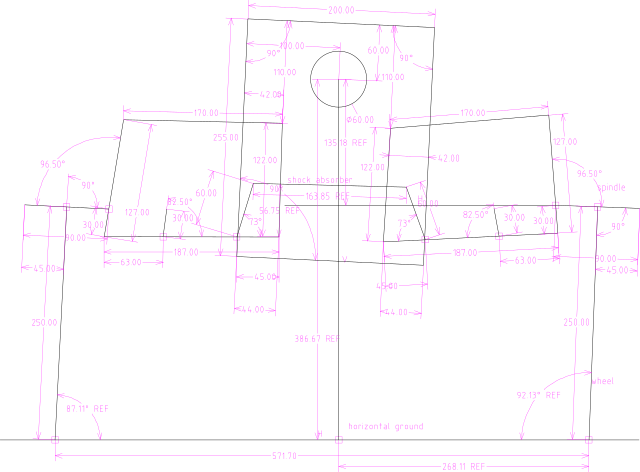

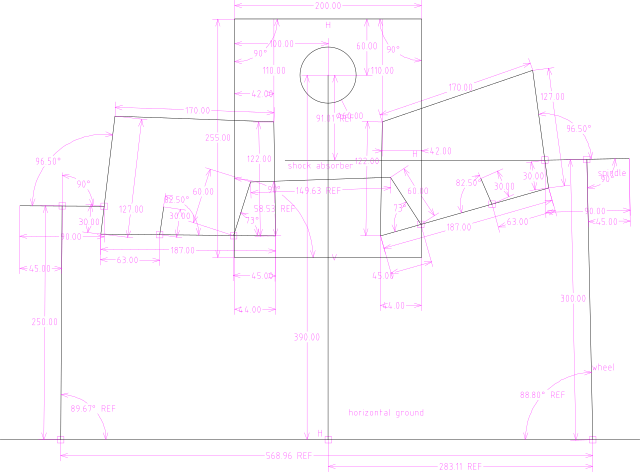

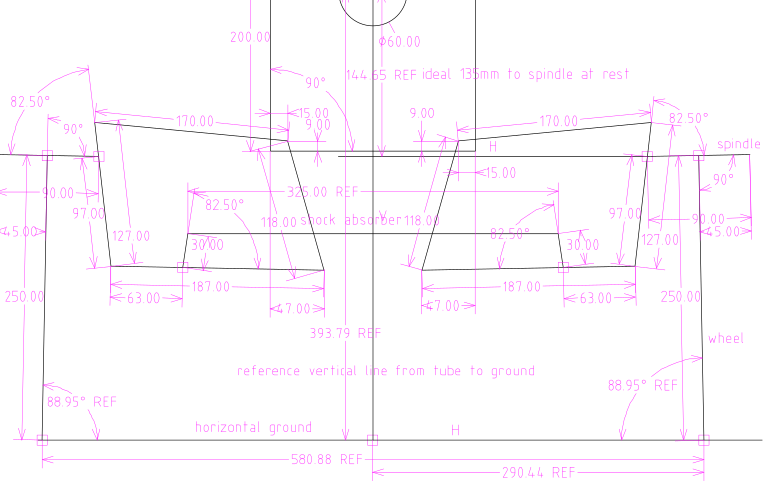

The go-kart suspension kit came with two 222mm shock absorbers, but I also bought a couple of 165mm shocks. This design is using the latter, as it is perhaps a bit neater, keeping the shocks mounted low-down:

...the two shocks are mounted at a common point called the "slider". If this slider is fixed in place, then the trike becomes non-leaning. The slider is attached to the "rod" and can slide along it. The intention is that the slide will be controlled by a linkage from the steering. In SolveSpace, pushing the slider along the rod, shows that leaning occurs:

...what possible downsides could there be for this design? Well, if a wheel hits a bump, there will be some kickback to the steering. That could be eliminated by a worm-gear drive linkage, but perhaps that is an overkill. A steering dampener could also be used, which is probably what I will do -- especially as one came with my trike.

Will it be difficult for the steering handles to slide the

slider? If required, the linkages could provide some mechanical

adavantage -- hmmm, which might also increase kickback.

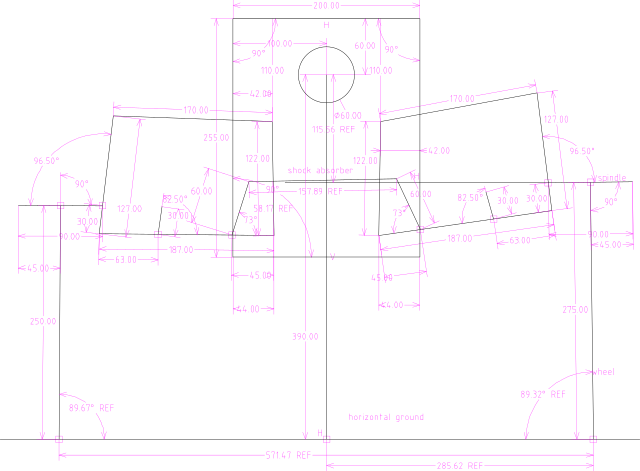

An alternative is to use the original 222mm shocks that came with the go-kart front suspension kit. Then, the slider would be much higher:

...the almost 80 degree angle of shocks to slider would mean far

less kickback to the steering.

Currently I am favouring the 165mm shocks. The 222mm shocks would mean the slider will be close to the rider's legs, not quite sure if too close.

Still haven't figured out the linkage from slider to the steering mechanism; kicking that can down the road.

Note, that second photo came from a fascinating web page:

https://www.thesuntrip.com/en/the-most-incredible-solar-bikes/

EDIT 20231118:

This rod-and-slider design is continued in the next blog post:

https://bkhome.org/news/202311/two-shock-design-with-curved-rod.html

Tags: light

Graham's simple DIY trike build

Continuing the trike project, previous post:

https://bkhome.org/news/202310/leaning-trike-single-shock-suspension-revisited.html

This post is a digression, thinking about various other approaches...

There are lots of Do-It-Yourself (DIY) trike builds on YouTube;

however, Graham's project is one of the simplest and most detailed.

Graham has done it without any welding. Here are his YouTube videos, in

chronological order:

diy trike build

https://www.youtube.com/watch?v=BBp47Pvp4CQ

steering geometry

https://www.youtube.com/watch?v=nrwPbg91fB8

part 1

https://www.youtube.com/watch?v=9DKgYVZTbKI

part 2

https://www.youtube.com/watch?v=4-VZ1QhZMKY

part 3

https://www.youtube.com/watch?v=JtN7lGss23I

part 4

https://www.youtube.com/watch?v=iYV-T02XU-g

part 5

https://www.youtube.com/watch?v=Mm20VcANAkw

part 6

https://www.youtube.com/watch?v=OhFYDE0yG8M

Graham's trike only has rear suspension, nor is it leaning; however, it is an excellent base for implementing those features.

With the knowledge I have accumulated so far, I reckon if starting the project from scratch, an attractive proposition would be to buy a couple of cheap Kmart full-suspension 20" bicycles. They only cost AU$129:

https://www.kmart.com.au/product/50cm-trax-dual-suspension-bike-43305209/

...reckon that has everything needed for a trike project. Steel frame,

which is very good, as it can be cut up and welded -- so, would need to

be able to weld.

But, would prefer disk brakes. Maybe a couple of secondhand bikes could be located with disk brakes.

One thing I have learnt is the bicycles have different wheel spindle

diameters (that is, the diameter of the central hole when the wheel is

removed). Mountain bikes are 12mm, 15mm or 20mm spindle diameter. My

Motrike/Trikexplor trike has 20mm front wheels.

Likely the Kmart bike has small diameter spindle, which might be

considered inadequate for trike front wheels, due to the spindle only

being supported on one side. A leaning trike would improve that

situation; however, there will be forces trying to bend the spindle when

hits bumps on the road.

Interesting thoughts anyway. This post is just contemplating

possibilities, not what I will do, as already commited to a certain

build. Continuing the contemplation, a trike could be built with both of

those front forks as-is, providing front suspension and spindle support

on both ends.

Fascinating! I can see why guys beaver away in their garage for

years. I was recently reading a forum post, a guy said that he tinkered

with trike DIY designs over 14 years, and it is still a

work-in-progress.

Tags: light

Leaning trike single-shock suspension revisited

The previous blog post considered a design with two shock absorbers:

https://bkhome.org/news/202310/tyre-scrubbing-on-trike-with-dual-shock-suspension.html

And before that, a single-shock-absorber design was considered:

https://bkhome.org/news/202310/tyre-scrubbing-on-trike-with-suspension.html

The single-shock design is simple, so decided to revisit it. But, a major rethink of the dimensions.

I found this video useful:

https://www.youtube.com/watch?v=4vtOcou_qXQ

...he rejected the single-shock design, but I have figured out the

coordinates such that it looks like the best option considered so far. I

do not need the extreme lean that he wants for his velomobile; my trike

will be trundling along at around 25km/h maximum speed, no fast

cornering.

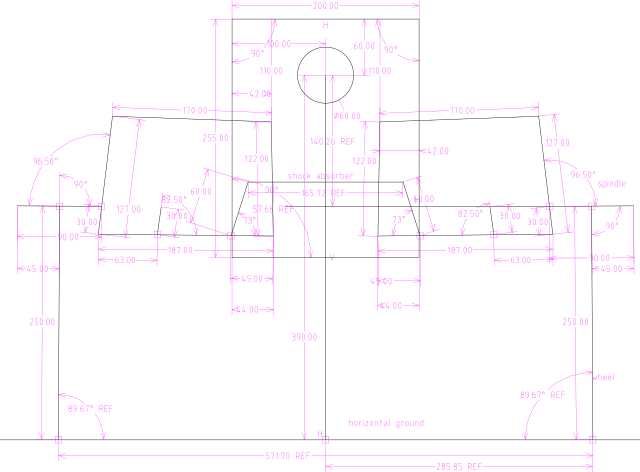

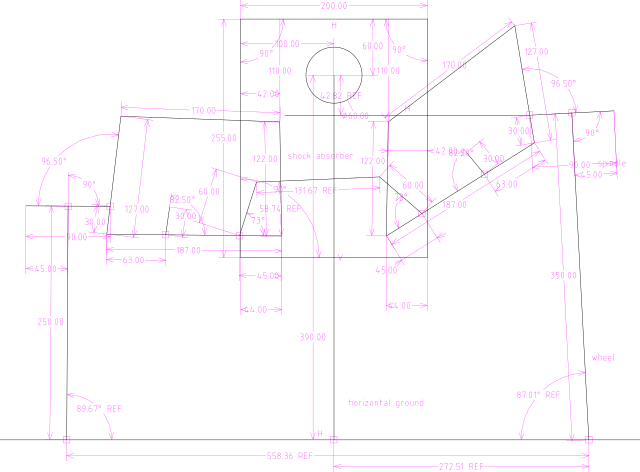

Here is the SolveSpace design:

The SolveSpace file, with false ".gz" appended, is here.

I decided on a 165mm shock absorber. Reason is, there is a vendor on

Aliexpress that sells 165mm shocks with a range of spring strengths.

From memory, I think from 350 pounds to 1500 pounds. They are just

coils, without any air or oil dampening; don't know if that will cause

the front of the trike to bounce around excessively. Have no idea what

spring strength will be best; most of the weight of the trike will be

toward the back, so a lighter spring is probably going to be the best

choice.

As before, a graph showing scrubbing when both wheels hit a ripple on the road:

...I optimized for small ripples. A 20mm vertical deflection of the

wheels has negligible scrubbing. 30mm has 2mm scrubbing, which is 1mm

per wheel.

This next image shows how much the rider can lean into a corner. The

limit is that the inner-mounting of the lower-wishbone will touch the

side of the shock absorber. But, 64 degrees, that is, 26 degrees off

vertical, seems like plenty:

...see those 60mm struts supporting the shock absorber; the length

could be increased if more lean is wanted. The above diagram is probably

not the same as the true situation when cornering; haven't taken into

account the extra weight of the trike while cornering causing the

shocker to compress, which should increase the ground distance between

the wheels a little bit.

One thing we do not want, is to fall sideways when the trike is

stationary. It will be hard-limited anyway, to 64 degrees. But, we

really want for the trike to stay vertical. Nominal vertical stability

while stationary is achieved due to the front tyres being a fixed

distance apart. In this situation, this diagram shows what happens if

there is a slight lean:

...the slight lean causes the shock absorber to compress. In the

above diagram, it has compressed about 2mm. Thus, the trike should stay

upright; "touch wood".

As stated, suspension has been optimised for small bumps. This also

applies to one wheel hitting a bump, for example, a 25mm (1 inch) bump. I

simulated it by increasing the radius of the right-side wheel:

...no scrubbing. Test a 2 inch bump:

...about 2mm scrubbing. Now hit a massive 4 inch rock:

...the shock absorber is getting close to it's compression limit.

Tags: light

Tyre scrubbing on trike with dual-shock suspension

This post is a continuation of the previous post, except

considering using the wishbones as they are intended, with two shock

absorbers. Previous post:

https://bkhome.org/news/202310/tyre-scrubbing-on-trike-with-suspension.html

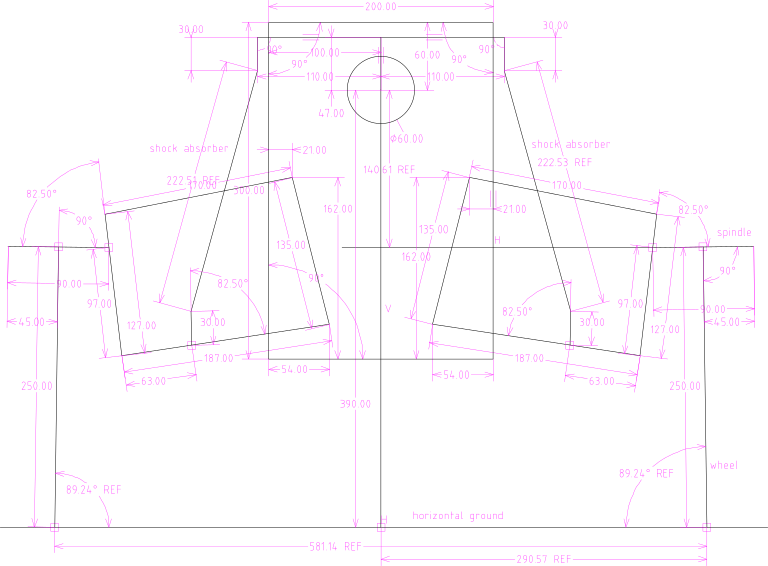

SolveSpace design, using the 222mm shock absorbers that came with the wishbone kit:

...the shock absorbers are connected at the top by a pivoted bar; the

horizontal line joining them is pivoted in the middle, to allow for

leaning.

I played around in SolveSpace, and this design looks good. The shock

absorbers only allow 50mm compression; however, this results in 75mm

vertical displacement of the wheels. That's just on 3 inches, before the

shock absorbers reach their limit -- they have a rubber stopper to

lessen the impact if the limit reached.

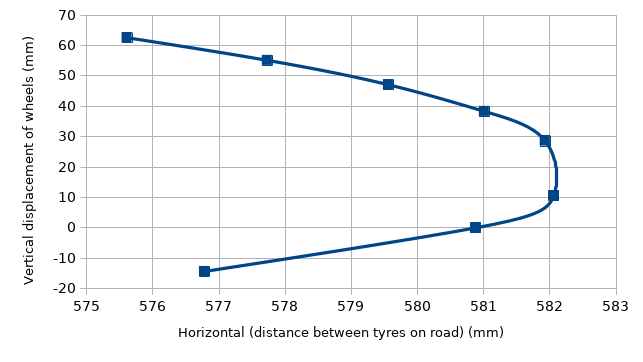

Plotting it, like did before:

..."0" on the vertical axis is when riding along on a smooth road. Hit a

ripple that sends both wheels up; can go up 3 inches before the shock

absorbers reach maximum compression.

For 50mm vertical deflection, scrubbing is about 2mm each way; about

1mm per tyre. Well, it depends where set the "0" point; could move it up

a bit on that curve and get close to 0.5mm per-tyre each way for 30mm

deflection. Maybe a bit of tweaking of wishbone mounting coordinates can

improve that curve a little bit more.

In SolveSpace I played around with leaning and single-wheel

deflection. For example, if one wheel hits a bump and is deflected up

50mm, the shock absorber on that side reaches maximum compression, and

horizontal scrubbing on the road between the two wheels is only 0.35mm.

So, hitting a bump on one side, there is less vertical travel that will

be cushioned. There is a limit on amount of lean allowed, as a shock

absorber will hit the top wishbone -- easy to put a limit on leaning to

avoid that.

Tags: light

Tyre scrubbing on trike with suspension

Continuing the custom tadpole trike project, with solar panels and leaning front suspension. Previous blog post:

https://bkhome.org/news/202310/design-of-front-suspension-for-leaning-recumbent-trike.html

...in that post, there is a link to a video with an animation of a leaning trike design. Here it is again:

https://www.youtube.com/watch?v=c3a0sSPOhb0

...watch just the first 20 seconds, and notice what happens when both

wheels are equally deflected. That is, weight has been applied downward

so both wheels are moved vertically by an equal amount. Notice the

distance between the tyres on the ground: they move inward, toward each

other.

This sideways movement of the tyres on the road surface is known as

"scrubbing". It happens in a car when you corner hard; the tyres scrape

sideways on the road. Ripping off tread.

It is not just when cornering; most suspension designs exhibit

scrubbing when the wheels hit a bump in the road. I want to optimise my

custom trike to handle corrugated gravel roads, in which both wheels hit

the same bump and get deflected upwards equally. The situation as shown

in the above video.

There are photos of corrugated roads in rural Australia posted to this blog. Here is another, taken at Cape York (photo from here):

...I chose this photo as it is representative of most corrugated

roads; fairly "mild" ripples, but still car-destroying. Here is an

example of more extreme ripples (photo from here):

...these roads will quickly erase the tread on the tyres for the

suspension design in the above video. I have looked at other trike front

suspension designs (leaning and non-leaning) and they all have this

scrubbing effect. The ones that I have seen anyway, though mostly I have

studied personal projects, not commercially manufactured trikes.

My trike design has double-wishbones, very short length. There is

going to be scrubbing. The focus is on minimizing it for the particular

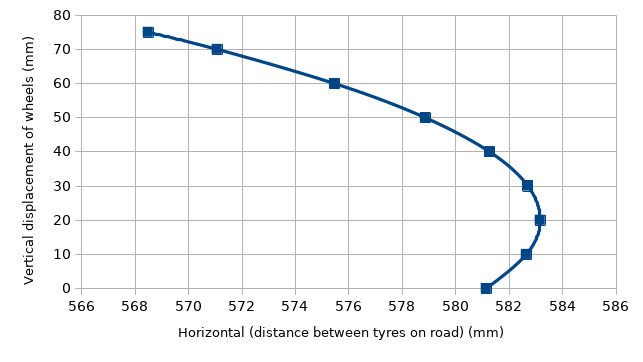

situation of corrugated roads. Here is the latest SolveSpace design:

...riding on a corrugated road, the wheels hit a ripple and get

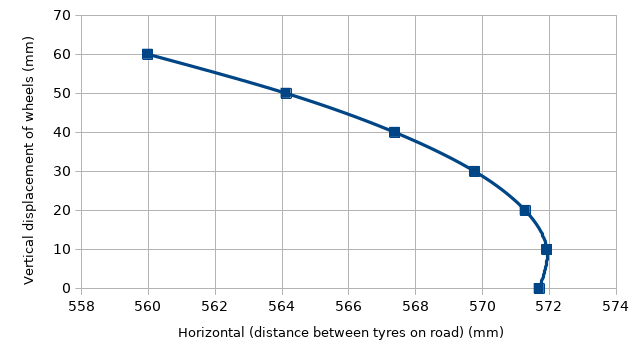

deflected upward. Using SolveSpace, I plotted values, vertical

deflection of the wheels against scrubbing on the road surface:

...the "0" on the vertical axis represents the rest point; riding along

on a smooth road surface. Hit a ripple and the wheels deflect upward. A

vertical deflection of 10mm causes just over 1mm scrubbing (the

horizontal axis). 40mm vertical deflection and scrubbing is back to

almost zero. 60mm (2.4 inches) vertical deflection and the tyres on the road surface

will have scrubbed inward (toward each other) about 5mm; that's about

2.5mm on each tyre.

After a lot of playing with SolveSpace, that seems optimum. It is a

compromise. It might even be negligible. I optimized for 40mm (1.6 inches)

vertical travel, the tyres will wobble about 1mm outward then 1mm

inward (0.5mm on each tyre). As deflection increases, camber will increase negatively (top of

wheels moving inward), and will probably run a fairly low tyre pressure

on those roads, both of which may lessen the effect of the scrubbing.

So, my reasoning is that 0.5mm per-tyre either way is negligible.

Note, I am deliberately limiting the vertical travel to 50-60mm

maximum, so no cushioning for bigger bumps. There are issues with

steering linkages; maybe trouble if too much vertical travel,

particularly with the tie-rods and toe setting.

I'm a suspension neophyte, so the above is just my

beginner's reasoning. We shall see. Get it wrong, and the tyre tread

will get worn out very quickly.

Tags: light