Heim versus ball joint

A few weeks ago, I admired Tomek's "Street Fox" DIY recumbent trike front suspension:

https://bkhome.org/news/202402/trike-front-suspension-using-tie-rods.html

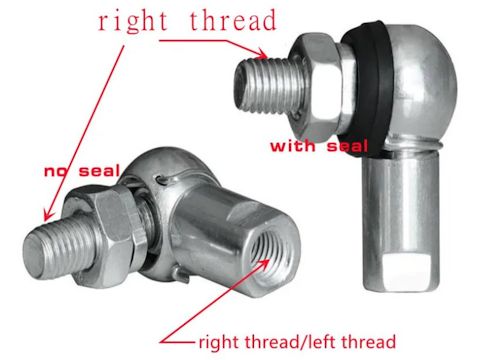

Those type of joints are known as "Heim" joints, as distinct from normal ball joints. These are also known as "Rose" joints in Britain.

There is at least one trike manufacturer using the same technique; Stein Trikes (based in Serbia). See video about the "Wild One" trike front suspension and a snapshot from the video:

https://www.youtube.com/watch?v=-TBdcZqQ_g0

I did some reading-up on Heim joints. Two major problems; they do

not have high axial strength, and secondly they can wear out

quickly.

That bottom joint is the main concern. You can imagine, if the wheel hits a bump, there will be a severe upward force, that the lower swing-arm will resist due to the shock absorber, hence strong axial force trying to rip the joint apart.

Then riding in inclement weather, rain and dirt will get into the

joint. On dry dirt roads, dust will get in.

So, it seems to me, that bottom joint will have a limited lifetime. But does that matter if the joints are cheap?

I purchased three different types of joints, to compare. Firstly, Heim joint:

I bought the cheapest, m10 thread and hole diameter, they cost only about AU$3.50 each and AU$2.50-ish postage. Postage remainded about the same for bigger quantity. Ha ha, compare with RS Components here in Australia, they are asking AU$45 each (plus postage?). eBay AU vendor wants AU$25 each plus AU$10 postage.

Maybe these ones from Aussie vendors are higher quality. Perhaps they have higher axial strength. The couple that I purchased from Aliexpress look okay, just eyeballing them.

I also purchased this ball joint:

As far as I can make out, it looks like the ball has been inserted from the bottom, which means that it cannot be pulled out. That is an important point for the bottom joint in the swingarm that you can see in the Stein Trike photo.

I found, however, that the join is incredibly stiff, and when I did get it to move, it did so very jerkily. It would probably loosen up in time, I suppose. The Heim joint, in comparison, moved freely, without feeling loose.

The third one I purchased is this:

Also a bit stiff to move, but again I suppose it will loosen up with usage. I pulled that little spring clip out, thinking that would allow the ball to be pulled out; but no, it is locked in, as shown in this section view:

I don't think that this would last if used upside down. For that bottom joint in the swingarm, there would have to be a bracket so that the joint can be bolted on right-side-up.

Both of those last two have rubber boots, so very good protection from water, dirt and dust.

Having a respite from the DIY trike project while my thumb heals; it has been an opportunity to rethink the design. Lots of thoughts, will post when something definite is decided. Definitely don't want to start from scratch; will use parts already constructed, such as the steering knuckles.

One very interesting bit of information; Stein Trikes did design

a full-suspension leaning trike about 9 years ago, named "Wild

Wave". There were prototypes but it never went into production.

From a couple of short videos, it looked like the leaning was

purely by body lean, not via the steering mechanism.

Tags: light

Trike front suspension using tie-rods

I'm always on the look-out for ideas for simple construction of front suspension for a recumbent tadpole trike. A few days ago, came across this:

"Evolution of my Street Fox trike to full suspension e-trike"

https://www.youtube.com/watch?v=KOeiWURsPlA

Tomek has built his own trike, "Street Fox", and in the above video has shown how he converted to full suspension.

It is a very simple design, using tie-rods. These are readily available, in various lengths. Here is a snapshot from the video:

...welded the tie-rods together, and he has swing-arms! Very

nice.

Tags: light

Construction of trike front suspension pivot

Continuing the recumbent trike project, here is the previous post:

https://bkhome.org/news/202401/starting-assembly-of-trike-front-suspension-frame.html

The two shock absorbers meet at a central point, and that is where it gets very interesting. The design is such that the trike can be tilting or non-tilting. If tilting, it can be achieved by either balancing, like on a bicycle, or by linkage with the steering. The idea is to experiment with all three.

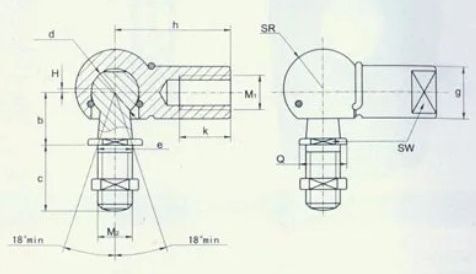

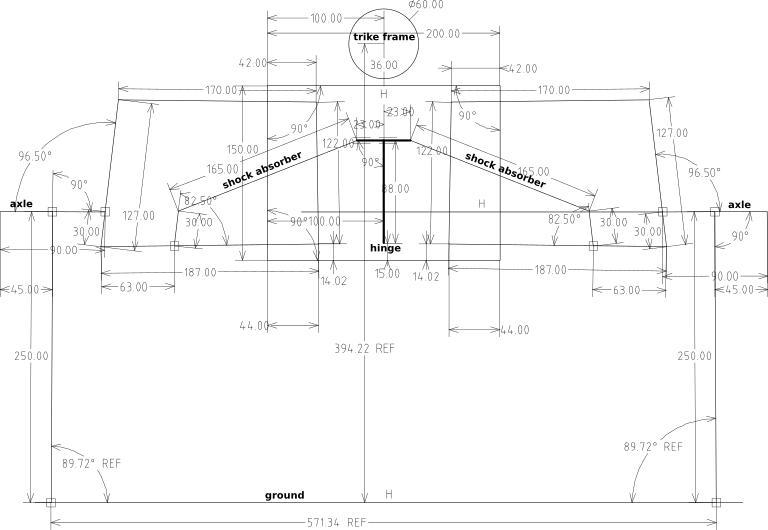

In November 2023, I posted how the central pivot of the shock absorbers will work:

https://bkhome.org/news/202311/two-shock-design-with-swinging-steering-linkage.html

Reproducing the drawings here:

...if that pivot is locked in place, then it is a non-tilting trike. If allowed to swing, it becomes a tilting, or leaning, trike:

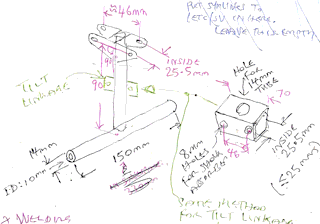

I don't have a nice drawing of that pivot, but have taken a snapshot of a rough sketch, that should give enough detail:

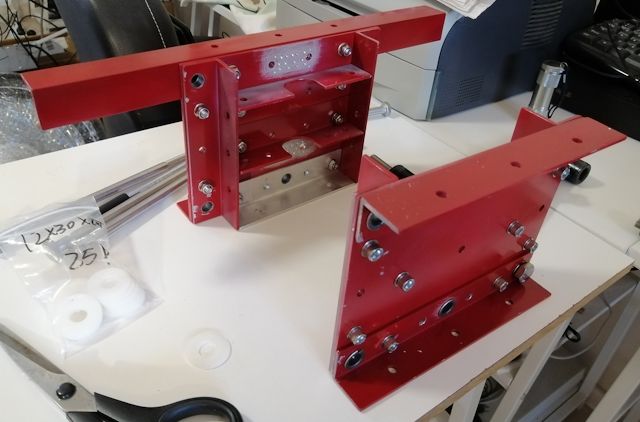

This is where some welding is required. Here are the two parts of the pivot:

|

|

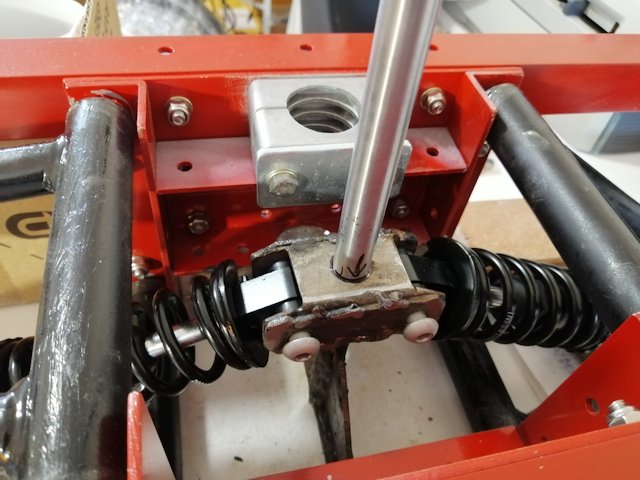

...the welding is not pretty, but looks strong enough. Small bushes have been inserted where the shock absorbers are attached:

|

The bushes are 8mm inside, 10mm outside, 6mm long, ordered as "d8D10L6" from here. The pivot tubing is 14mm OD, 10mm ID, mild steel, from here. |

I did a temporary assembly, to determine the weld-point for joining the two parts of the pivot:

Consequently, the two parts were welded together:

This pivot design is very experimental, and it is going to be a fascinating experience to test it and compare the three modes; non-tilting, free-tilting and tilting linked to the steering. Progress is slow, and cannot say when the trike will be basically operational. Ha ha, as I learn, keep getting ideas about a trike "mark 2" version.

Tags: light

Starting assembly of trike front suspension frame

Here is the previous post, of the recumbent trike front suspension conversion project:

https://bkhome.org/news/202401/construction-of-wheel-knuckle-hinges-and-learning-to-weld.html

As already mentioned, the swing-arms and knuckle came as a

go-kart front-suspension kit. Which has proved to be a challenge,

mostly due to the sloppy pivot points. I mentioned in the previous

blog post that brass bushings were inserted to reduce the

sloppiness.

The swing-arms have m10 bolts, but the hole they slide through is about 11mm. So, as for the knuckle, inserted brass tubes to act as bushes. In this case 11mm OD, 10mm ID, 0.5mm wall thickness, bought from here. I didn't buy enough brass tube, so mixed with some aluminium tube purchased from here. Brass would have been best I think, from the point of view of wear and less likely to corrode when wet and in contact with iron.

The m10 bolts supplied with the kit were not long enough, so bought 200mm length off eBay. That was the longest that I could find, stocked anywhere in Australia. I thought that could get away with that length; however, it is still not enough:

...only about 5mm before the thread starts, whereas want 9mm. Even worse, want to put in some nylon spacers. I hunted on Aliexpress and found some longer ones, a vendor that sells m10 up to 300mm. So, there will be a delay while waiting for them to arrive. In the meantime, there are other jobs to do...

Notice one thing in the above photo; the plastic plugs at each end of the swing-arms is, I thought, not a very good fit. So I epoxied them firmly in, using metal-repair epoxy, which is epoxy with silicon and iron powder. It is available all over the place, got it from here.

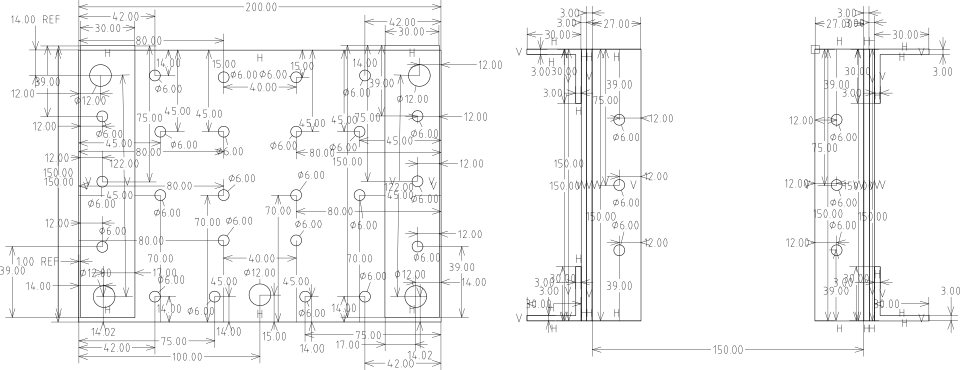

The SolveSpace design of the front suspension frame is here.

It has a false ".gz" appended, so just rename the file. Exported

as PNG:

It is only a 2D design; how it goes together is in my head, but this photo should help:

...the swing-arm hinge-points have brass bushes, that can be seen in the above photo. The holes in the aluminium are 12mm and the bushes are 10x12x10x18, sold here. They are a firm fit and needed to be hammered in.

To show what it will look like, here is a partial assembly, with the swing-arms attached:

As will become clear in future blog posts, the design is

adaptable to different implementation strategies. For example, it

can be tilting or non-tilting. Next-up, plan to install the

shock-absorbers, which will involve some

welding.

Tags: light

Construction of wheel knuckle hinges and learning to weld

Continuing the full-suspension solar electric tadpole recumbent trike project, this is the previous post:

https://bkhome.org/news/202312/construction-of-front-axles-for-custom-trike.html

...which describes modification of the front-wheel "knuckles" for a bicycle wheel with 20mm diameter shaft. I recently learnt the name for that part. Here is a photo of a wheel knuckle for a different trike project, made by Tony:

...I won't post the link, as it is from a private Facebook group. Tony is an Aussie, who built seven recumbent trikes, but now due to age has had to stop riding them. Tony's welding ability exceeds mine. The knuckle consists of the spindle for the wheel, the central "kingpin", and brackets for disk-brake calipers and steering linkage.

The go-kart kit that I purchased via Aliexpress is very cheaply

made, and the pivot-points are all very sloppy. If the hinges are

sloppy, then it will mean the wheels will have some "play" and

will wobble while in motion. This is bad for the handling and will

also cause fast tread wear.

So, I have been reducing the play in all the hinges. The knuckle came with a M12 bolt, whereas the kingpin tube that it slides into is about 13mm inside diameter. Actually, a tiny fraction over 13mm. To fix this, I bought some brass tube, 13mm OD, 12mm ID, 05mm wall thickness (from here), and slid a piece of it into the kingpin:

...fantastic, the bolt is now a snug, but not tight, fit.

One detail: the kingpin tube, into which I slid the brass tube, has a raised seam its entire length. I took that out with a round file, before inserting the brass tube. Looking ahead to contruction of the swing-arms, to be described in a future blog post, the tubes were much longer and I took out the seam with a drill bit in a lathe:

The bolt was not quite long enough, so I bought one with a 120mm total shaft length and about 32mm thread length. Got it off eBay, with 1.25mm pitch fine thread:

https://www.ebay.com.au/itm/333361108883?var=542408508784

...that was the longest I could find, but still not quite long enough, as you should be able to make out from this photo:

...the threaded part of the bolt is going through the U-piece and is another very sloppy pivot-point. To fix this, I welded a nut onto the U-piece, into which the bolt will screw. Also, at the other end, welded a small rectangle of iron, with a hole so as to grip the bolt more snuggly. Here are photos of the U-pieces:

...the welding is not beautiful, but does the job.

Actually, I didn't do that welding, it was done by Terry. He is a retired school teacher who used to teach metalwork.

This is a workshop that I have joined, mostly retired guys, and today Terry was extremely helpful. He did the above welding with a MIG welder, and gave me instructions how to use it. I brought in my arc welder, and Terry gave me instructions how to strike a spark and get a nice weld-run. This is the arc-welder that I purchased a little while ago, in anticipation of needing it for the trike project:

https://www.ebay.com.au/itm/272834881672

...that helmet thing is useless, so also purchased an auto-darkening helmet:

https://www.ebay.com.au/itm/401641355188

I practised with this welder, but had great difficulty, mostly

because the rod sticks to the work-piece.

Today, Terry tested my welder with different rods, and we found one that strikes very easily; "CIGWELD Ferrocraft 21" 2.5mm diameter (see here). In fact, I was amazed how easily it struck and didn't stick. Amperage was set to 115A, and thickness of the workpiece is also a factor, so that particular rod worked well for that situation.

An extra note about the MIG welding that Terry did. He had difficulty with getting a bond to the U-pieces, which contributed to the messy appearance. We think that the coating is "yellow zinc" -- whatever, it was a problem.There will be some more welding required for this trike project,

and that is going to be mild-steel, so should be easy. In fact, I

should be able to handle it myself with the arc welder. Lots of

fun!

Tags: light

Construction of front axles for custom trike

Continuing the full-suspension tadpole trike custom project. Previous blog post:

https://bkhome.org/news/202311/beware-cheap-drill-bits.html

Earlier in the project, I purchased this go-kart front suspension kit:

https://www.aliexpress.com/item/1005005943611409.html

...shipping cost was high. Shipping from China is higher than it used to be, pre-pandemic. One comment: having gained more experience with bicycle components and general metalwork, if starting from scratch now, would be tempted to manufacture it myself. Another comment: it is cheaply made, sloppy "bearings".

There is a problem with that kit; the wheel axles are 15mm

diameter. However, my trike front wheels require 20mm

through-axles. The through-axle for bicycle wheels can be 10mm,

12mm, 15mm, up to 20mm for premium mountain bike.

Another problem; the axles do not have brackets for disk brakes. So, I bought these; 17mm diameter shaft and with disk brake mounting brackets:

https://www.aliexpress.com/item/1005003033562914.html

These axles have two problems; 17mm diameter, whereas I need 20mm, and the shaft is stepped, up to 19mm near the disk-brake mounting bracket. So, I machined it down to 17mm, as close to the disk-brake bracket as possible:

...after taking that photo, put it back in the lathe and machined an extra couple of millimeters...

The diameter of the axle was brought up to 20mm by a sleeve; an aluminium tube, of 17mm ID and 20mm OD, bought from here:

https://www.aliexpress.com/item/1005004347889082.html

There was yet another problem; the shaft was not quite long enough, so as to be able to screw the nut onto the threaded end far enough to insert a split pin. Fortunately, I found "concave washers" and bought the M10x40x1 size:

https://www.aliexpress.com/item/1005005527446669.html

This photo shows the entire assembly:

...the copper washer is M17x30x2, from here:

https://www.aliexpress.com/item/1005003020060256.html

The concave-washer has a 10mm hole, so had to drill it out to 14mm. That was a challenge, as the work-piece has to be held firmly. I may have gone a bit overboard in that regard; it is certainly held firmly...

...I moved the workpiece slightly and increased the hole diameter to about 15mm.

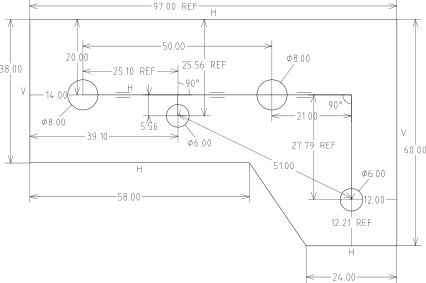

Next job, constructed adaptor-brackets to hold the brake calipers. Used some 3mm thick aluminium plate, it is type 6061 or 7075, not sure which, these dimensions:

The SolveSpace file, with false ".gz" appended, is here.

The adaptor plates drilled and cut-out:

Assembled:

...will replace those long M8 bolts with shorter ones, and use lock-nuts.

There are some finishing-off details to do.

For example, the 20mm OD aluminium sleeve and 17mm steel shaft are different metals, that will cause corrosion of the aluminium and rusting of the steel when wet. The intention is to smear epoxy resin around the steel shaft and slide the aluminium sleeve over it, providing a barrier. Will also use thin silicone washers as water barriers each end of the axle.

The aluminium adaptor-plate will be painted, probably black.

Going slowly, but it is a fun project. More challenges ahead, and some details not yet worked out. Now for something completely different; photo of a beach visited recently...

...those dots in the water are people. Mid-summer here in Australia.

EDIT 20231227:

I bought the complete go-kart suspension kit, as shown in the

first photo above, then replaced some items, such as the

steering-knuckles and shock-absorbers. So, if you are interested

in building a front suspension similar to mine, the

suspension-kit can be purchased in parts.

For example, the wishbones/swing-arms can be purchased alone:

https://www.aliexpress.com/item/4000056825228.html

Regarding the steering-knuckles, there are alternative designs, such as this:

https://www.aliexpress.com/item/1005004116654463.html

...the above has a 17mm diameter axle, but I see also there are

steering-knuckles available with 20mm axle.

Tags: light

Enclosed pedal-powered recumbent in production

I hunted around, trying to find any enclosed (with canopy) recumbent three or four-wheel pedal-powered vehicles, with electric assist and maybe solar panel, in production. There are lots of projects that never made it into production, and some that were briefly in production but no more.

I found one that is, apparently, in limited production, the "pedilio":

https://www.pedilio.de/news-english/about-pedilio/

...in Germany. Cannot find a price. Very nice specifications, full suspension, solar panel.

The pedilio looks like it would be legal in Australia, except that it is a quad. Oh, and 870mm wide, so not legal in WA. In Western Australia, the definition of a bicycle is 2 or 3 wheels:

“bicycle” means —(a) any 2 wheeled vehicle, not being a scooter, that is

designed to be propelled solely by human power;

(b) any 3 wheeled vehicle, intended for use on a road,

that is designed to be propelled solely by human

power; or

(c) a 2 wheeled or 3 wheeled vehicle that is a power

assisted pedal cycle;

...no mention of 4 wheels.

I'm not sure, but I think some other States define a bicycle as being "2 or more wheels". Ah yes, South Australia:

https://www.sa.gov.au/__data/assets/pdf_file/0020/23438/DPTI-Cycling-and-the-Law-Booklet.pdf

A bicycle is classified in the Australian Road Rules as being anytwo or more wheeled vehicle that is built to be propelled by

human power through a belt, chain or gears (whether or not it

has an auxiliary motor) and includes a pedicab, penny-farthing,

tricycle and a Pedalec.

While hunting for bicycle definitions, stumbled upon this 2022

update to the maximum width allowed for a bicycle in WA:

Dimension requirements for bicycles and their loads

The overall width of any equipment or load carried on a bicycle

must not exceed 800 mm.

[Regulation 406 amended: SL 2022/130 r. 5.]

...the wording is weird. Doesn't say the bicycle itself can be

800mm wide. But the "660" limit has been removed, so 800 must also

mean the bicycle itself, not just load/equipment.

So, can update this blog post:

https://bkhome.org/news/202311/updated-maximum-width-of-bicycletricycle-in-wa.html

EDIT:

Rick sent me a link to the "Veemo" enclosed trike, apparently

starting production in Canada:

https://envodrive.com/products/veemo

...not a recumbent, so quite tall; not leaning either, so the

thought occurs it might be a worry when cornering. Can't find a

width specification.

Tags: light

Beware cheap drill bits

I learnt something very important today. Continuing the custom trike project, previous two posts in what is turning out to be a very long saga:

- Updated maximum width of bicycle/tricycle in WA — November 18, 2023

- Two-shock design with swinging steering linkage — November 18, 2023

There will be 10mm shafts to mount the wishbone swing-arms, inserted at each end in an aluminium plate. So the aluminium plate will have holes, that the shafts go through, with locking nuts on the outside.

I decided to insert bushings in the holes, so as to have a wear surface between shaft and plate. So, bought some of these, 10mm ID, 12mm OD:

https://www.aliexpress.com/item/1005005339265328.html

I have access to a workshop, but the set of drill bits kept near the drill-press did not have a 12mm size, so I bought this one from Bunnings:

https://www.bunnings.com.au/full-boar-12mm-m35-cobalt-drill-bit_p0328195

...a cobalt drill bit, price AU$14.26. Bunnings also have 12mm

cobalt bit, Kango brand price AU$41, Sutton brand price AU$61. So,

a considerable cost saving!

Today at the workshop, drilled some test holes in some scrap 5mm thick aluminium. Used the drill-press, and the aluminium was held in a vice and was immovable. Drilled the hole, but the bushings were a sloppy fit. In other words, the drill bit cut with a slight wobble. Until the last about 1mm when it broke through the other end of the aluminium plate, then it cut the last 1mm correctly at exactly 12mm diameter.

I found another 12mm drill bit at the workshop and tested that. It cut a nice 12mm hole and the bushing was a snug fit.

So, why did a brand new drill bit cut with a slight wobble?

There is a guy at the workshop who explained the cause of the problem. He explained that the cutting edges of the drill bit are not exactly equal on each side of the central point. He used a grinding wheel to improve it, but explained that it might take some experimenting to get it right. He also explained how to test that both sides have been cut evenly.

The lesson is that those cheap drill bits at Bunnings are not

necessarily a cost-effective buy.

Tags: light