Recumbent trike front suspension Mark-3

I posted about Mark-2, with a photo mounted on the trike frame:

- Recumbent trike front suspension Mark-2 assembled — May 17, 2024

In the last few days, posted about tackling steering linkage for the Mark-3 design:

- Ackermann steering compensation — May 31, 2024

- Trike steering cannot kick the can down the road anymore — May 23, 2024

In the last several days, have been constructing the Mark-3 frame. This is welded, using 20x20mm, 1.6mm wall thickness, carbon-steel tube. As I am a beginner-welder, I have found that thin steel to be a challenge; it is too easy to burn a hole right through it. The workshop that I go to, has a lot of scrap metal, and I since found some 20x20 with 2.5mm wall thickness, that I started to use after having constructed most of the frame.

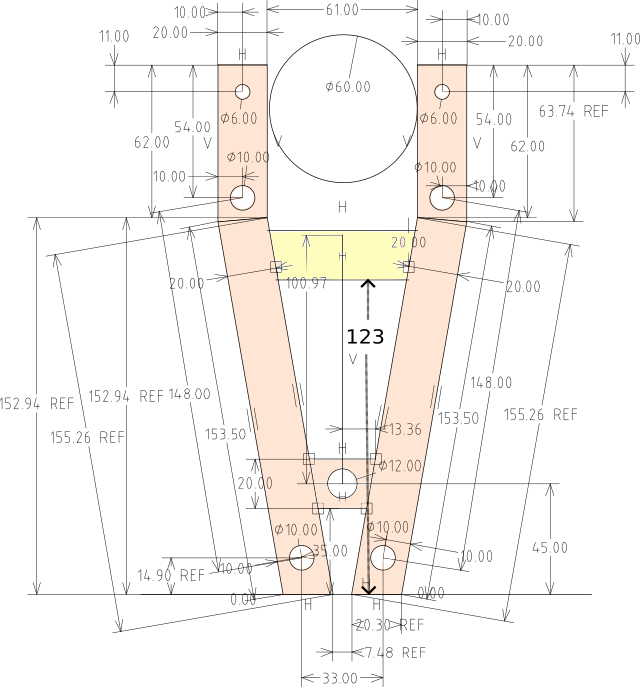

In that last link above, I posted a drawing of the end-view of the frame. A slight modification when I constructed it; moved the piece shown in yellow down a few millimetres:

...one of the pipe-clamps will be bolted onto that cross-piece and I decided to give it a bit more distance from where the Heim joints will be bolted on.

After welding these two end-frames, to make sure that the holes are aligned, I clamped the two frames together and drilled through, as shown:

...note, the four holes for the Heim joints are 10mm, the one shown being drilled is for the shock-absorber pivot and is 12mm.

The side-pieces are 90mm long, and to get them reasonably accurately in place, I inserted m10 bolts, then turned the whole thing on the side (bolt heads on the bench), inserted the side-pieces, clamped, then welded. This shows the inserted bolts:

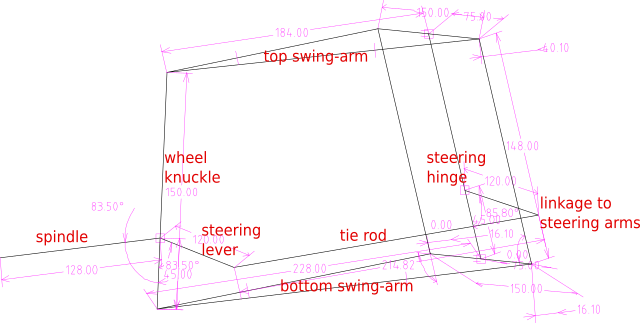

Here are the measurements for the side-pieces:

...the bottom side-piece is special; although welded to sloping

off-vertical end-frames, it is oriented with sides horizontal and

vertical.

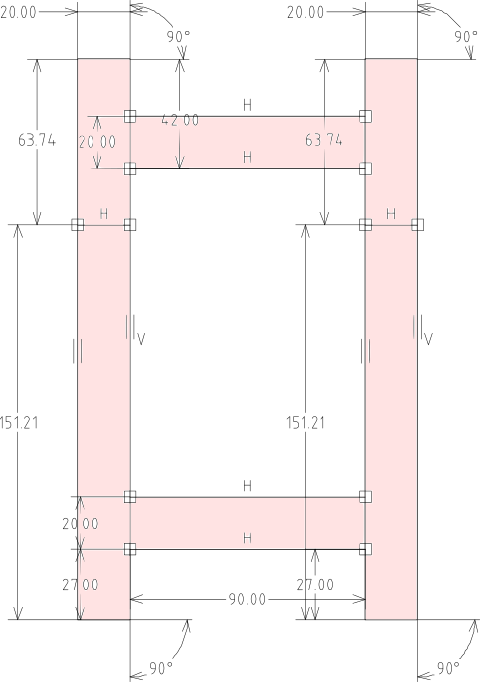

Fully-welded frame:

...the red lines show holes drilled for mounting the pipe-clamps (actually, I drilled 6.5mm holes, though the bolts are only m6). The holes for the bottom pipe-clamp are right against the side wall of the square tube, so I welded some small pieces to strengthen the side-walls and also welded a backing-plate, as shown by the blue lines. The reinforcing is probably unnecessary; I'm just being ultra-cautious to make sure it is going to be strong enough when taking a pummelling.

Notice that the bottom side-pieces have a 6m hole in the middle.

That is for the steering linkage, and more details will be

forthcoming.

The shock-absorbers mount on a pivot, that can optionally convert the trike to be tilting. Here it is temporarily inserted:

...alongside the Mark-2 frame. The phone wide-angle lense gives the mistaken impression that the Mark-3 is about the same size as the Mark-2; in fact, the Mark-3 is quite a bit smaller. I have designed the Mark-3 to be as small as possible; one problem that arises is that the shock-absorber pivot will require something more to lock it in place. The photo shows its height:

...a flat plate is required to go across horizontally, though which a m10 bolt can be inserted to lock the pivot, for a non-tilting trike. The ends of that plate will have to be bent down and welded to the frame. I intend to do that at the workshop on Monday.

Note, I constructed that shock-absorber pivot for the Mark-2, in late-January. Here are the details:

- Construction of trike front suspension pivot — January 30, 2024

...I could have built another, a bit smaller for Mark-3, but it

is OK, using it as-is.

I temporarily attached the pipe-clamps, to show how the frame will fit onto the trike:

...due to the smaller size of Mark-3 frame, the 30mm aluminium tube is too long; it will need to be cut off. Flush with the pipe-clamp, to allow enough space for the bolt to which the shock-absorber pivot is mounted. Another job for Monday.

A bit more work required on the frame; when finished will probably paint it flat-black to hide the sins of my welding. Note, there will be some extra bracketing to attach the frame to the trike tube, so not relying totally on just those pipe-clamps.

Here is the SolveSpace design of the Mark-3 frame, file renamed with false ".gz":

https://bkhome.org/news/202406/images/frame-14g.slvs.gz

Tags: light

Ackermann steering compensation

A few days ago I posted about problems with the steering linkage introduced by having shock-absorber suspension:

https://bkhome.org/news/202405/trike-steering-cannot-kick-the-can-down-the-road-anymore.html

Another problem is tyre scrubbing when turning a corner. If both

front wheels are parallel, when turning a corner, they will be

fighting each other. They are following the same radius, whereas

the inner one should be following a smaller radius.

This might seem unimportant; however, for a fairly tight corner,

say a radius of 2 metres, the scrubbing will be serious. The

effect is noticed as tyre squeal and premature wear. I suppose the

premature tyre wear is going to happen even for large turning

radii.

Ackermann steering geometry corrects for this, causing the inner wheel to follow a smaller radius than the outer wheel. There is a wikipedia page:

https://en.wikipedia.org/wiki/Ackermann_steering_geometry

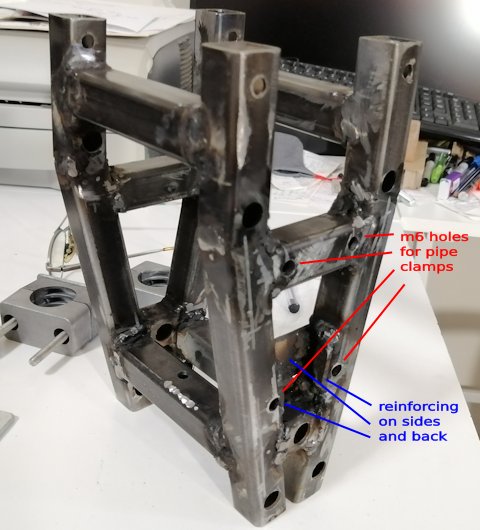

As I explained in my earlier blog post, I cannot have a tie-rod directly from the steering arms to the wheel-knuckle, as most trikes do. Instead, I have to do it indirectly, as this very rough sketch shows:

As I pointed out before, exactly how this works will become clearer when photos, even a video, is taken of the contructed trike suspension.

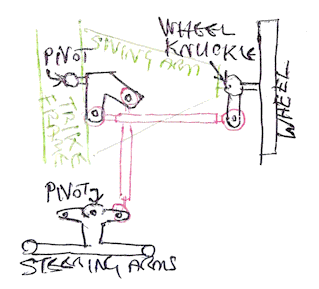

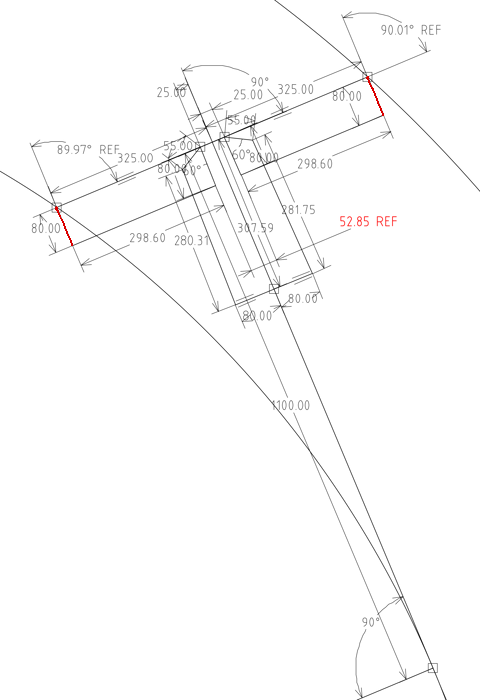

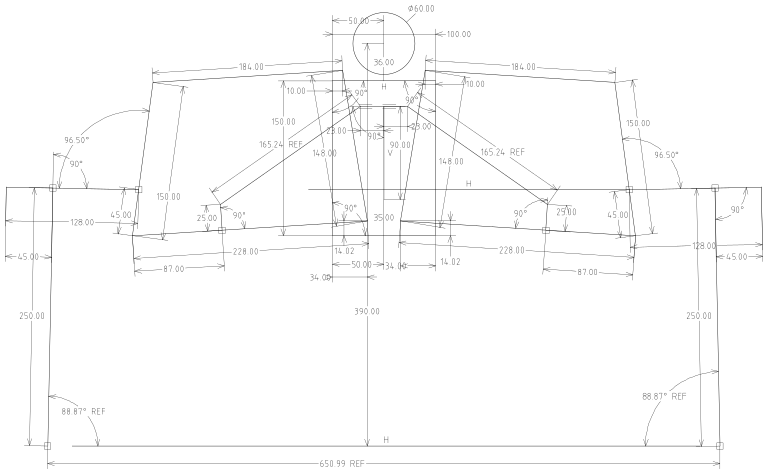

By appropriate geometry, the above design also implements Ackermann compensation. This diagram created in SolvSpace, with dimensions approximately those of my trike, shows both wheels pointing straight ahead:

...the two red lines are the levers attached to the wheel-knuckles. The lines marked as length "298.60" are tie-rods. Notice especially the "52.85" distance between the tie-rod ends.

If the steering arms are turned, so will the front wheels. Those two red lines are the wheel direction. Here is the wheels turned to follow a 2 metre radius:

...those two curves are concentric, that is, the same central point. The inner circle has a smaller radius than the outer. The inside wheel has turned more than the outside wheel, so they are both following concentric circles around the same point. Thus there is no tyre scrubbing.

Notice the "43.70" distance. This shows that the inner wheel has

been turned more than the outer. As also shown by the angles of

wheels relative to the swing-arms.

Here is the SolveSpace diagram, with a false ".gz" appended to the filename:

https://bkhome.org/news/202405/images/ackermann-5.slvs.gz

The project is moving along; there will be more posts coming

soon.

Tags: light

Trike steering cannot kick the can down the road anymore

Here are the last two blog posts on the trike full-suspension project:

- Weight of an electric recumbent tadpole trike — May 18, 2024

- Recumbent trike front suspension Mark-2 assembled — May 17, 2024

As can be seen in the second link, a photo shows the "mark-2"

tilting front suspension mounted on the trike. Getting to this

point has been very good, has enabled me to see how everything

will fit together.

One problem I have identified is that the suspension frame is too wide for the chain. The chain runs from the back wheel to the pedals right at the front. The chain can be negotiated around the suspension frame, but it is awkward. I never thought that would be a problem until the suspension was mounted on the trike.

So, I am going to change the suspension frame to be narrower. That's one thing. Another factor is more serious; linkage to the steering arms. I had "kicked that can down the road", thinking will solve it later. Well, "later" has arrived.

Most recumbent trikes do not have front suspension. This greatly

simplifies steering linkage to the steering arms. With what is

called "indirect steering", there are arms either side of the

seat, that the rider swivels to steer. Similar to a bicycle

handlebars.

Here is a document that describes different steering linkage designs:

http://www.ihpva.org/projects/practicalinnovations/weld.html#Steering%20Systems

In a nutshell, the wheel knuckles have protuding arms, that are connected via tie-rods to the steering arms. Conceptially, it seems OK, except if front suspension is introduced it may become a mess. Here is a photo underneath a Stein Trikes full-suspension Wild One tadpole trike:

...you can see how the steering arms are hinged, with tie-rods going to the wheel knuckles. The fundamental problem is, that if a front wheel hits a bump, it is going to pull on that tie-rod, causing the wheels to twist (scrub), and potentially causing feedback to the steering arms. Or, if both wheel hit a large bump, causing both wheels to twist, even potentially breaking the tie-rods.

Note, the above snapshot is taken from here.

The fix, if possible, is to set the tie-rod end-points such that when the wheels hit a bump, the tie-rod will deflect but without pulling or pushing on the steering arms nor try to twist the wheels.

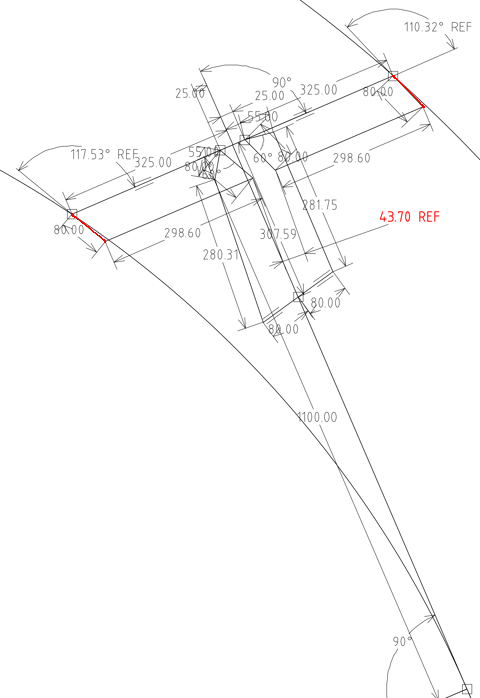

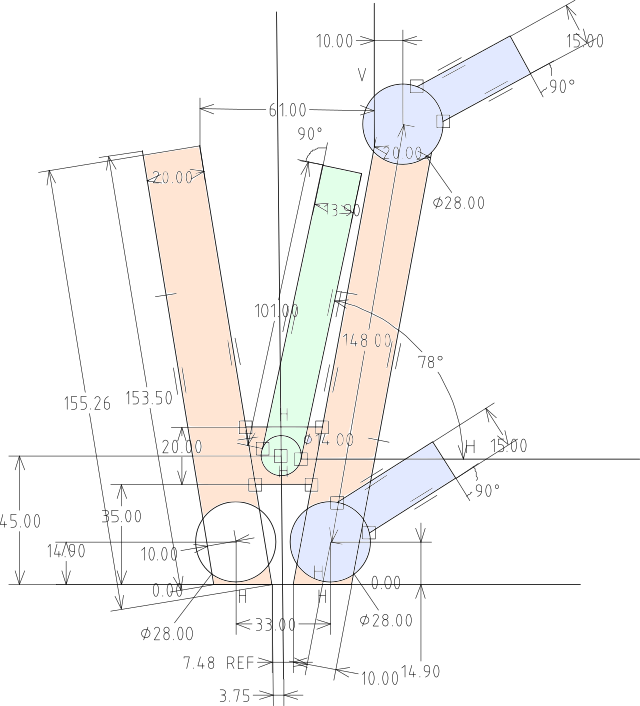

I don't know how well Stein Trikes have reached that ideal objective. But, I have figured out the basics of how it can be done. Here is a 3D simulation in SolveSpace:

...this is difficult to explain. The concept is in my head, and will be best explained after it is built and photos, even videos can be taken. Bearing in mind that the above diagram is conceptual, and implementation will be different; the basic idea is that the tie-rod end mounting-points are such that no matter how much the wheel is deflected upward, the distance between the tie-rod end-points remains constant.

In this design, the tie-rods from the steering arms are not connected directly to the wheel-knuckle levers; instead just one linkage required, to the point labeled "linkage to steering arms". Thus, no matter how severe the terrain being ridden on, there will be no deflection forced back to the steering arms, nor any force trying to twist the wheels.

A caveat to the above paragraph; vertical force on the wheels

will not be reflected back to the steering arms. However, as the

wheels are mounted on one side only, there will be a twisting

force, that will deflect back. Most trikes have a dampener, that

also came with my original trike, that I will re-use.

As I say though, the concept is in my head, and the validity

will, hopefully, become apparent when it is built. This linkage

will require certain accomodations in the suspension frame,

lacking in Mark-2.

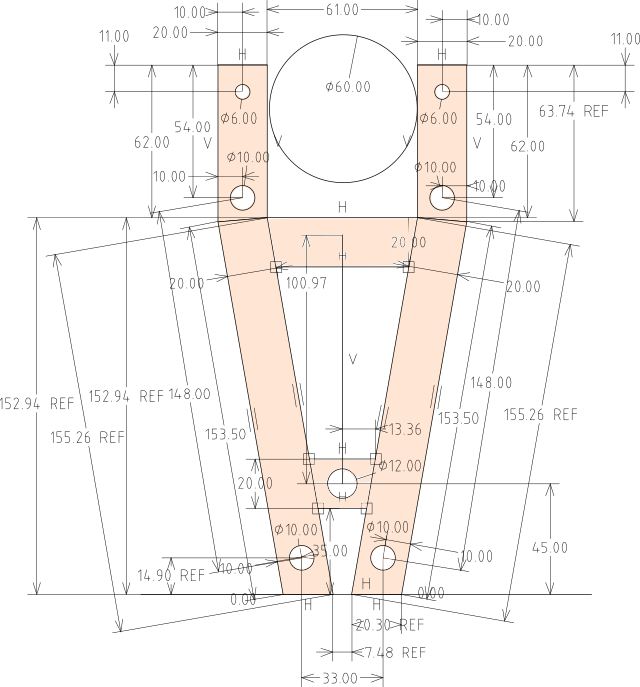

I have to move on to "Mark-3" front suspension design. Basically the same as Mark-2, using most of the same components. I am replacing the wood frame with welded steel tubing. Here is what it will look like viewed from the front of the trike:

Here is another partial representation, showing how the Heim joints are attached on one side:

...light-blue are the Heim joints. Light-green is the pivot inside, where the shock-absorbers are attached.

On both sides, there will be hinges attached, that swivel

horizontally. This is the "steering hinge" in the second photo on

this page.

The steel that I intend to use for the frame is 20x20mm 1.6mm thick, this:

I obtained some free, hence it is the obvious choice to use. I'll be back at the workshop, practicing welding. Hopefully will improve skill welding such thin tube, and knock up the frame.

EDIT 2024-05-25:

I was looking back through links posted earlier to this blog,

and followed a link to a series of videos on a velomobile

project, by Alex, via his "MetalMachineShop" YouTube channel.

Previously, had only watched the first few; this time watched a

later video in his series, on steering linkage. This is part-14:

https://www.youtube.com/watch?v=5wpujxKvJQk

Yes, he is using the same method that I am planning to use:

...the central idea anyway. There are

implementation differences.

Tags: light

Weight of an electric recumbent tadpole trike

In a post yesterday, I showed a photo of my Mark-2 front suspension mounted on the trike frame:

https://bkhome.org/news/202405/recumbent-trike-front-suspension-mark-2-assembled.html

I picked up the front of the trike, and using a block of wood, put it into my bathroom scale. Weight is 13kg. Obviously that is not the weight of the entire trike. So what does an "entire trike" actually weigh?

Here are some very basic trikes, without any front or rear suspension, non-electric:

https://mrrecumbenttrikes.com/newtrikes/

...weight is around 18 - 20kg.

A motor and battery adds about 10kg, bringing the weight up to nearly 30kg. Add rear and front suspension, adds even more, quite easily hitting 35kg. Here is an example, electric tadpole trike with 500W motor, 20Ah 48V battery, rear suspension, no front suspension, 20" fat tyres, the same company that makes my "320" trike, weight 38kg:

https://www.alibaba.com/product-detail/500watt-Motor-20ah-Lithium-Battery-Electric_62583559842.html

Could you lift a 38kg trike? I could, if I want to put my back out.

These weights put things in perspective; I don't need to obsess over making the front suspension very light. A couple of extra kilos doesn't matter. Here is the original front assembly for my trike:

...weight is 6.5kg. That is the cross-beam to which the wheels will attach, and the steering.

Notice that aluminium plate bolted to the cross-beam. That is the mounting to hold the battery. Interesting, they decided to put the battery right up the front. If I do that, with my front suspension, that would be good in one respect; dampening bumps. On the otherhand, I have fairly soft suspension up front, so will need to experiment how to distribute the weight.

While that original front assembly was on the floor, took the

opportunity to measure total width, that is, right to the ends of

the wheel spindles. 915mm! Oh man, that is wide. The

police in WA might turn a blind eye to bikes, trikes and mobility

vehicles being a bit too wide, but if I was to ride that on a

footpath, even a dual-purpose footpath, if the police person was

in a bad mood, they might be inclined to book me. Another reason

to do a custom front suspension.

The original battery, also weighed that, 5.5kg:

Note, I'm not going to use that battery in the trike. Main reason, it is "NMC" technology, as are in most bikes, trikes and scooters. NMC means Nickel Manganeses Cobalt, also known as "lithium ternary" batteries. Apart from the ethical issues how those minerals are mined, NMC batteries have shorter life and are more prone to catching fire than "LFP" technology batteries.

LFP means Lithium Iron (ferrous) Phosphate. These do not have any nickel, manganese or cobalt. They are also slightly cheaper than NMC. The downside is that they have lower energy density, which would be the main reason they aren't used in bikes and trikes.

LFP are also named LiFePo4, which is the standard for caravans, motorhomes and other RVs. They are not so bothered about energy density.

I purchased a 10Ah 48V LFP battery from China (with matching mains charger), and will be using that. As I am planning to be solar-powered, I reasoned that smaller capacity is OK. And it will save about 3kg.

So what else is really heavy? The motor. Here is the motor assembly, without pedals, weight 6kg:

So, the original battery and motor weigh 5.5 + 6 equals 11.5kg.

Wow.

Tags: light

Recumbent trike front suspension Mark-2 assembled

Continuation of the recumbent trike front suspension conversion project, this is the previous blog post:

https://bkhome.org/news/202404/connecting-trike-front-suspension-to-frame.html

I am referring to this as "Mark-2", as there was an earlier design that I partially built then abandoned.

There is going to be a "Mark-3", as I already have in mind many improvements; however, I intend to progress the Mark-2 right through to a rideable trike. The reason for doing this, is there are so many more parts of the trike that have to be built and tested.

The steering for example. There are a lot of questions about that, so have to experiment. Mark-3 is intended to be based on the same dimensions, and whatever is worked out for the steering in Mark-2 should be directly applicable.

Anyway, here is Mark-2 front suspension assembled on the trike:

As you can see, I decided to go with the Heim joints; however, not for Mark-3 as I have conceived of a simpler and likely lighter design for the swing-arms.

The shock absorbers are quite soft, rated at 200 pounds per inch. That was the softest available for that model of shock absorber. Sitting on the trike, suspension seems OK, but won't really know until it is loaded and out on the road. There will be a lot more weight up front due to the electric motor, and I will probably mount the battery at the front. The next rating-up is 350 pounds per inch; anyway, we shall see how it goes.

The suspension retains the ability to be a tilting trike, as where the two shock absorbers meet is a pivot. It is currently locked in place, but by simply removing a bolt it will swing freely. The intention would be that the central pivot will be linked to the steering mechanism, so that the trike will tilt when cornering.

At this stage, don't know if will ever get to implementing the tilting. It depends on cornering stability. My trike is only 750mm wide, measured from the extreme ends of the wheel spindles. The main reason for that is I want it to fit through my front door, so can keep it inside. Also, if I go touring and stay overnight in a motel, want to be able to bring it into the room.

All recumbent trikes (that I know of) are over 800mm wide. My "320" trike is, or rather was, I think, 870mm. Making it narrower will decrease cornering stability. But this is where I need to get out on the road and find out whether 750mm width is OK, or whether have to go for tilting. I'm not going to be racing around corners, so likely it will be OK.

I should also mention that here in Western Australia, the legal

maximum width is 800mm. Which means that, technically, all

recumbent trikes in WA, apart from mine, are illegal. Not that

anyone is bothered by that. Prior to June 2022 here in WA the

legal maximum width was only 660mm, but the police turned a blind

eye to trikes and mobility vehicles that were wider.

Anyway, it is continuing to be a fun project, as is going to the

workshop.

Tags: light

Connecting trike front suspension to frame

Continuing my recumbent trike front suspension project, this is the previous post:

https://bkhome.org/news/202403/considering-heim-joints-for-wheel-knuckles.html

Getting close to putting it together, decided today to post about an aspect of the project that is rather weird...

My trike is a TrikExplor/Motrike with a "320" frame. There are various models based on this frame, for example:

https://www.motrike.com/product-item/rear-suspension-recumbent-trike/

So, there is a central frame tube, and a cross-beam to which the

wheels are attached. Where the weirdness comes in, is the

cross-beam is attached to the central frame at a hinge-point,

complete with ball bearings ...except, it doesn't actually hinge.

If you look carefully at the above photo, there is another member

coming out from the cross-beam and attached to the central-frame,

locking the cross-beam at 90 degrees to the central-frame.

Hinging, that is, steering, occurs at the wheels, as is done for all recumbent trikes.

So why the ball-bearing join, when it doesn't hinge? The only reason I can think of is that the 320 frame was designed as a basis for many different trike designs, including the possibility of swivelling the entire cross-beam.

When I bought this, I hardly knew anything about trike design.

Soon after buying it, I was thinking, if starting again, I would

buy a more "normal" trike frame; however, most trikes weld the

cross-beam onto the main frame, so I would have had to cut it off,

then weld new framework. Messy; at least this 320 frame, though

weird, does make it easy to detatch the cross-beam and fit

something new.

I think that a lot of these have been sold in the USA, so if someone reading this can obtain a secondhand one cheap, with a view to modifying it, then this blog post provides some useful information.

What I needed is a tube that will slide into the ball bearings, with some means of attaching a framework. This is what I put together:

The tube is 30mm OD aluminium, which is a perfect fit. Well, not quite. It is a perfect fit for the top-most bearing, but there is a very slight sloppiness sliding through the bottom bearing. Reason is, the tube needs to be painted, then the bottom bearing becomes a snug fit.

When I inserted the tube and pulled it out, the bottom bearing came out, that you can see in the photo. To the immediate right of the bearing, there is an adapter-ring that I took off the trike. Then to the right of that is an aluminium sleeve that I cut to length, so as to fine-tune the height of the suspension-frame relative to the trike-frame. That sleeve is 30mm ID, 40mm OD, but I had to sandpaper the inside a bit to get it to slide over the 30mm OD tube.

Here are where I obtained the parts:The 30mm pipe clamps. But, I see right now they are out of stock. Perhaps there are metal ones elsewhere in Aliexpress. There are plenty of plastic ones available, which would probably be strong enough. This is where I got mine:

https://www.aliexpress.com/item/1005005478071535.html

I purchased 30mm OD, 20mm ID, 240mm length aluminium pipe. Length is exactly right. Thicker wall than really needed. From here:

https://www.aliexpress.com/item/1005004347889082.html

The aluminium sleeve is 40mm OD, 5mm wall thickness, 100mm length, from here:

https://www.aliexpress.com/item/1005005964994480.html

I spray painted the tube with an etching primer, followed by a red gloss enamel. Just one thin coat of each.

A bit of a hassle attaching to the trike frame, but probably

better than having to cut off a cross-beam and weld new framework.

Hmmm, but I am going to end up needing a bit of welding to the

trike frame anyway.

The actual front suspension is just about ready to be put together; that will be a future blog post. That piece of pine is misleading; there is a lot more to it, with metal reinforcing.

EDIT 2024-05-13:

Regarding that aluminium sleeve, OD 40mm, ID 30mm, height 25mm.

A bit tricky to manufacture that in a home workshop. I had

access to a lathe, and was able to cut the ends very straight,

but extremely difficult if you cut the tube some other way, such

as with a hacksaw. Also, very difficult to sandpaper the inside

evenly, so as to slide over the 30mm tube.

I have ordered some aluminium washers, m30, OD 40mm, thickness 2mm, to be able to fine-tune the height of the suspension relative to the frame:

https://www.aliexpress.com/item/1005004593391252.html

But it occurs to me, for anyone reading this who might want to perform the same or similar modification to the front of their "320" trike, that it might be easier to make up the sleeve from lots of these washers. Glue them together. Just a thought.

Another thought, regarding those metal pipe

clamps. If only the plastic ones are available, they are

probably strong enough. I wanted to evaluate them, so purchased

a couple. Inside, they have some empty space, that could be

filled with epoxy to strengthen them.

Tags: light

Considering heim joints for wheel knuckles

Yesterday I considered ball joints on the wheel knuckles:

https://bkhome.org/news/202403/considering-ball-joints-for-wheel-knuckles.html

At the workshop today, I constructed another design, using two heim joints top and bottom:

The orientation of the heim joints has the advantage of allowing any amount of vertical displacement of the wheel relative to trike frame.

The downside is weight. It has the original m12 bolt, inserted through a steel tube with brass sleeve insert. I cut off the head of the bolt and welded it to the cube, as can be seen on the left of the photo. I didn't weigh yesterday's design when assembled, but estimating by weighing the parts, today's design is about 330g heavier. For both sides, that is 660g (0.73 Imperial pounds).

With the original trike suspension, that I had almost completed, I found that the weight had got much higher than desired. A bit of extra weight here and there; it adds up. In particular, the sprung part, the wheel knuckle, should be as light as possible. So, I am not going to take today's design any further.

I'll be back at the workshop after Easter, want to try one more

design variant. Oh yeah, Easter has rolled around again. Happy

Easter guys!

Tags: light

Considering ball joints for wheel knuckles

I posted about three different types of ball joints that I purchased for comparison:

https://bkhome.org/news/202403/heim-versus-ball-joint.html

Today I was at the workshop where retired guys get together and work on little projects. Lots of good equipment there. Thinking about what ball joints to use with the wheel knuckles.

Back in early January I was working on the wheel knuckles, intending to fit them to the cheap swing-arms that I purchased from China:

https://bkhome.org/news/202401/construction-of-wheel-knuckle-hinges-and-learning-to-weld.html

Various problems with those swing-arms. Sloppy pivots is the main problem, but also the design became very big and heavy; not really what I want for a trike. While my thumb has been healing, have rethinked the design; hence purchase of the ball joints for consideration.

The workshop has some old 40x40mm steel square tube, and I cut out some cubes. Actually that square tube is fencing post, available from Bunnings, but I found an old length to cut up. Here is the first consideration:

...the cubes are just balanced in place, to see how it will look. I won't rush into doing it this way, as it will be a one-way process; the cubes will have to be welded onto the wheel knuckle.

Any downsides? The main one will be limited vertical displacement, restricting how big a bump can be handled.

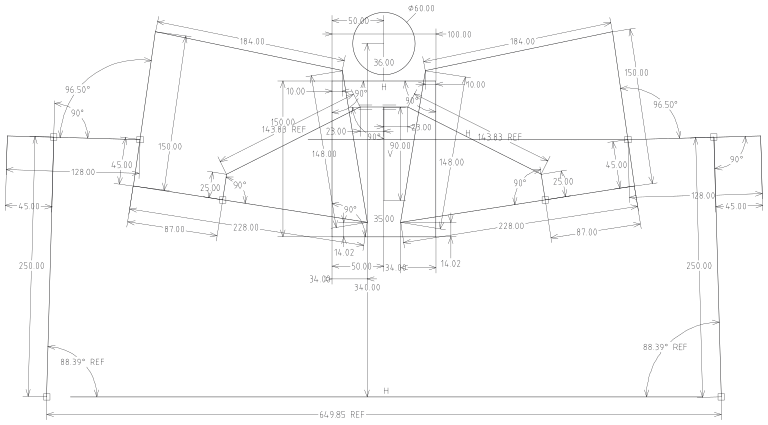

The spacing between the ball joints is ok. I looked at it with SolveSpace:

...notice that 390mm distance; that is the height of the trike frame above ground. That is intended to be the rest position, with someone sitting in the trike. The distance between the wheels on the ground is 650.99mm.

If the trike frame is pushed down, which would be the same as riding along and both wheels hitting a bump, this table shows how the wheel spacing (on the ground) varies:

| Height |

Spacing |

| 390 |

650.99 |

| 380 |

651.93 |

| 370 |

652.28 |

| 360 |

652.05 |

| 350 |

651.23 |

| 340 |

649.85 |

...wheel scrubbing is at most 1.3mm (0.65mm per tyre); negligible. Snapshot from SolveSpace, at height of 340mm:

...looks good. The ball joints could handle a bit more vertical displacement; just looking at it in SolveSpace, it seems the height could go down to about 320mm, at which point the shock absorbers would also be reaching their limit -- 70mm vertical displacement, a little bit under 3 inches. That's a pretty big bump.

Next-up will consider the wheel knuckle with heim

joints.

Tags: light