Wheel knuckle modifications

A few days ago, posted photos of the front suspension and steering assembled on the trike:

- Trike simplified steering linkage assembled — June 24, 2024

Have pulled it apart, to fix a few things. Firstly, the wheel knuckles. The history of these goes back to December 2023:

- Construction of front axles for custom trike — December 09, 2023

The design has evolved. Here is a later post:

- Considering ball joints for wheel knuckles — March 27, 2024

Here is a photo showing the axles on which the wheels will slide:

To finish-off the axle, the aluminium tube has now been epoxied firmly over the steel. I used cheap "Utility" brand slow-setting epoxy from Bunnings (my usual choice, far cheaper than the alternative brands, sets very hard), smeared it over the steel shaft, slid the aluminium tube over, and inserted a bit more epoxy into the top to fill up:

The turning radius of the trike was a bit too wide, so I used an angle grinder to cut the sides of the bottom steel cube to allow the ball joint to swing a bit more. Only cut out about 3mm, as the steering arms are also going to limit the turning radius.

Strengthened the bottom steel cube a bit by welding a plate on the back, as shown in the above photo.

Another problem was that the steering-lever extension was not held positively in place. If one of the bolts should loosen, the extension could move slightly. To fix that, welded the extension, also shown in the above photo. Left the bolts in place.

Finally, an etching primer and black coat:

Tomorrow can start re-assembling.

Tags: light

Trike simplified steering linkage assembled

A couple of days ago, I posted about a simplified steering linkage that I can put together quickly:

- Trike simplified steering linkage — June 22, 2024

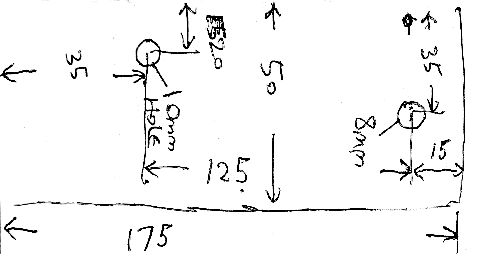

Today manufactured the wheel-knuckle lever extensions. Used 50x3mm cross-section mild steel. Here is a sketch:

Then assembled on the trike:

As stated before, there are lots of compromises with this simple linkage.

Fleshing out a bit more how I calculated the amount that the inner wheel was turning a bit too much...

The SolveSpace diagram shows two concentric circles, going through each wheel. The diagram also shows the angle of each wheel, relative to the trike frame. 90 degrees would be the wheels pointing straight ahead. If the diagram is adjusted so that the outer wheel is following the outer radius, we can subtract the two wheel angles to see how much the inner wheel has turned in or out relative to the outer wheel.

There is a formula for calculating the ideal angle for each wheel: A=atan(L/R)

Where L is the length from the front wheels to the hub of the

rear wheel. In my case 1200mm. R is the radius of the circle while

cornering. A is the angle.

For the example in SolveSpace of inner circle radius 3138mm and outer radius 3583mm, calculating the two required wheel angles:

Aouter=atan(1200/3583)

Ainner=atan(1200/3138)

Aouter=18.52°, Ainner=20.93°

Difference=2.41°

In the SolveSpace diagram, the difference is 3.31°, so the inner wheel has turned 0.9° more than the Ackermann ideal.

EDIT 2024-06-25:

I assembled the arms, so as to evaluate basic steering

functionality:

Have made a list of required modifications,

so tonight will completely dis-assemble the trike. Rebuild will

probably be about a month from now. Intend for it then to be

rideable and will use lock-nuts and thread-lock.

Tags: light

Trike simplified steering linkage

Continuing the tadpole trike front suspension project, here are recent posts:

- Trike 320 rear fork large gap fixed — June 21, 2024

- Trike hinge for steering arms — June 20, 2024

- Motrike 320 rear shock mounted with ordinary bolts — June 16, 2024

- Trike Mark-3 swing-arms constructed — June 14, 2024

- Trike 320 frame rear fork large gap — June 13, 2024

- Recumbent trike front suspension Mark-3 — June 01, 2024

- Ackermann steering compensation — May 31, 2024

...that last link describes a fairly sophisticated steering linkage mechanism, that provides Ackermann compensation and handles the shock-absorber suspension.

However, that linkage is complicated, and for now I just want to get the trike to a rideable state as soon as possible. So, have figured out a linkage design that is very simple and makes use of what is already available.

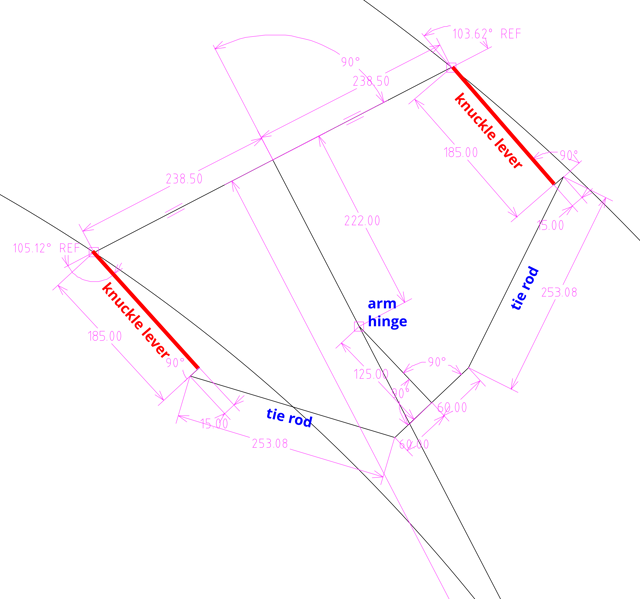

There are four tie-rods from the trike; the two shorter ones I will use. Also will attach them to the existing mount points on the arms-frame. This diagram shows how it goes together:

As using the existing tie-rods and arm mount-points, it requires

the knuckle-levers to be extended, as shown in red. The red lines

are parallel to wheel direction and there is a 15mm offset where

the tie-rods are attached.

There are all kinds of compromises.

There is Ackermann compensation, but not perfect. The lower-left curve is a 2m radius, the outer curve is a 2.4m radius. Circles are concentric. If the steering is turned so that the outer wheel is following the 2.4m radius, the inner wheel has turned a bit too much; 1.55° too much.

Turning a larger circle, 3.2m inner radius and 3.6m outer radius,

the inner wheel turns 0.9° too much.

Another compromise is that the steering arms swivelling is limited by the seat. This is going to limit turning to about a 2m radius. I guess can live with that.

If a wheel hits a bump, the tie-rod will cause the wheel to turn in or out slightly. I think that the tie-rod can be connected such that the wheel will turn slightly inward with a small bump, and slightly outward with a bigger bump. That situation would be improved with longer tie-rods; however, the other two that I have are too long, and I couldn't figure out how to fit them in, at least not without a huge amount of extra construction.

The only thing required to construct is the knuckle-lever extensions, that I will probably do on Monday.

Pretty much definitely will be wanting to modify this steering design later, but this will get me out onto the road quickly. I'm looking forward to experiencing how much the compromises affect the actual riding handling.

The SolveSpace design is here,

with false ".gz".

Tags: light

Trike 320 rear fork large gap fixed

I posted about this problem:

- Trike 320 frame rear fork large gap — June 13, 2024

The rear fork is this part shown in black:

Thanks to you guys who gave feedback about bending the fork closer. The wheel hub is 135mm, which is a common standard for bicycle rear wheels. However, the fork spacing is 140mm and is too stiff to pull in completely.

At the workshop I attend, received help from Terry, who is a retired school metalwork teacher. We set the fork into a clamp:

Terry advised to do the bend cold, not to heat the fork, so that's what we did.

At the back, we placed an anvil, on which to rest the other end of the fork. The clamp is used by the woodworking guys. I suppose that an ordinary large g-clamp could be used ...hmmm, maybe not, as some considerable force is required. We lubricated the clamp thread to help.

The thing is to clamp to a certain point, where upon release the fork and it springs back just a couple of millimeters closer than the original 140mm. We were very careful about this, clamping the fork, then releasing, then clamp a bit more, and so on.

Very interesting; it kept springing back to 140mm. But a point is reached where the frame will just start to deform. For us, it was when we clamped the fork to 110mm spacing, then released and it bounced back to 138mm.

138mm, that is perfect. Now, can tighten the skewer knob a

little, then flip the quick-release lever and the fork is now

properly gripping the wheel hub. This is good

news.

Tags: light

Trike hinge for steering arms

Continuing the front-suspension project of a tadpole recumbent trike, here are recent posts:

- Motrike 320 rear shock mounted with ordinary bolts — June 16, 2024

- Trike Mark-3 swing-arms constructed — June 14, 2024

- Trike 320 frame rear fork large gap — June 13, 2024

- Recumbent trike front suspension Mark-3 — June 01, 2024

Progress is slow, but things are happening. The most recent task has been to figure out a way to mount the steering arms. The TrikExplor 320 assembly manual has this photo, showing that the arms-hinge is bolted on the bottom of part of the cross-beam:

However, that cross-beam and welded-on extra pipework, is no longer there. So I had to manufacture something on which the arm-hinge can attach.

The arm-hinge, which is the pipework in black above, has bearings, so I had to make up something. Here are pictures. Firstly, aluminium tube 30mm OD, with dowel inside and 10mm hole in the middle:

Inserted into the arm-hinge:

A special flange is required on the underside of the bearing,

that will take the weight. These are a standard thing in bicycles

and if you have second-hand bikes you could probably get one off

the bike. I bought one from here, 30mm ID, open-type

https://www.aliexpress.com/item/1005004651506052.html

Another flange is required on top, for weather protection. The trike already had one, that I had removed. It has rubber rings inside and out:

...however, it is for a tube slightly less than 30mm, only very slightly, maybe about 29.5mm. So I filed it to fit the 30mm tube, but then cannot use the inner o-ring. Will use silicone sealant in the final assembly. Probably could have bought that as well, with the exact required ID.

Next, constructed an assembly that will bolt onto the trike frame. 40x40x40mm square steel, 12mm hole on top, 10mm on the bottom:

Got the m12 30mm bolt from here:

https://www.aliexpress.com/item/1005003279616641.html

The m12 nut, with serrations underneath:

https://www.aliexpress.com/item/1005006974699501.html

The washer shown in the photo is interesting; it has serrations on both sides:

https://www.aliexpress.com/item/1005006121408441.html

...bought them to experiment with.

Mounted on the trike frame, upside-down view:

Finally, the arms-hinge is mounted:

...looks like an improvised construction! The bolt is too long, hence the washers; but that can be fixed.

Next up, intend to put together the linkage from the steering arms to the wheels. I had previously posted about a linkage design that is optimised for the vertical movement of the suspension; however, to get going, thinking of a simpler design.

The optimised design is complicated; the simpler design I can

assemble very quickly. I want to get this trike to the stage where

I can ride it! Refinements can come later. For the simpler

steering linkage, I will need to do some modeling in SolveSpace

first -- probably tonight or tomorrow.

Tags: light

Motrike 320 rear shock mounted with ordinary bolts

I posted a few days ago about the poor construction of the rear fork:

https://bkhome.org/news/202406/trike-320-frame-rear-fork-large-gap.html

...which is strange, as I thought they would have used a jig to hold the pieces of the fork in place while welding. Maybe they did and the jig itself is wrong.

Thanks for the feedback guys, for recommendations how to go about bending the forks slightly closer. Yes, I have decided to do that. Here is a photo of the fork:

...it is the black part that I have removed and will bend.

That's when I made another unpleasant discovery. The shock absorber is mounted with ordinary threaded bolts:

...this is really bad, as it will cause premature wear of the mounting.

Proper shock-absorber mounting bolts should have been used, such as these:

I don't want to make any further comment about this, but to put

it mildly, I am unimpressed.

Tags: light

Trike Mark-3 swing-arms constructed

Continuing the saga, converting a tadpole recumbent trike to have front suspension, here are recent posts:

- Trike 320 frame rear fork large gap — June 13, 2024

- Recumbent trike front suspension Mark-3 — June 01, 2024

- Ackermann steering compensation — May 31, 2024

- Trike steering cannot kick the can down the road anymore — May 23, 2024

- Weight of an electric recumbent tadpole trike — May 18, 2024

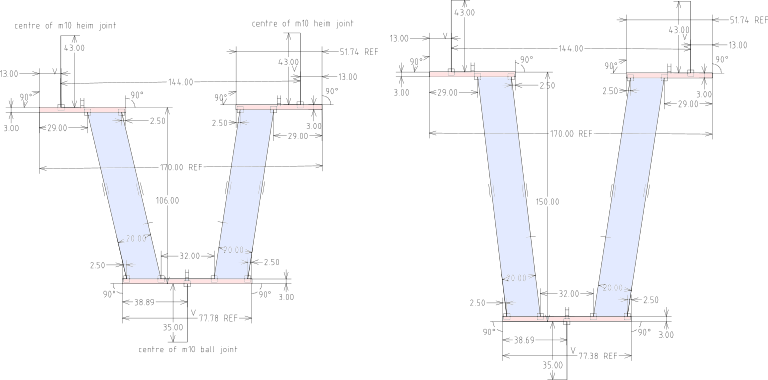

Mark-3 is a rebuild with steel, and welded. I have done the same also for the swing-arms (A-frames or wishbones). Here is the design:

Here is the SolveSpace file of the swing-arm design, with false ".gz" appended:

I used the same 20x20mm square tube as for the main frame. The

steel bar is 25x3mm.

Photo of the swing-arms and shock-absorbers attached to the frame:

...painted black, the welding looks OK!

Put it on my bathroom scale; just on 5kg. Not light, but as I

discussed in "Weight of an electric recumbent trike" post, see

link above, it is only a small part of the total

weight.

Tags: light

Trike 320 frame rear fork large gap

I have posted many times about this tadpole recumbent trike that I purchased direct from the manufacturer in China. It is a TrikExplor/Motrike with 320 frame. They have variant models with that same frame. There is a photo of the trike here:

https://bkhome.org/news/202404/connecting-trike-front-suspension-to-frame.html

Here it is again:

Overall, it is reasonable quality, except for one thing; mounting

of the rear wheel.

The frame is aluminium, including the rear fork. It is similar to

bicycles; there is a quick-release skewer that goes through. Here

is a photo showing what these skewers look like (my hub is 135mm):

https://www.pushys.com.au/bbb-wheelblock-100-135mm-quick-release-skewers-black-silver.html

You tighten it a bit, then flip the lever to lock the wheel hub to the fork. Except, I can't. Here is what it looks like before tightening the quick-release skewer:

Right, so I tighten the thread on the quick-release skewer as much as possible, then flip the lever:

...the wheel is supposed to be fully-seated, such that the fork presses against the wheel hub. But there is 2mm gap.

The rear fork is strong, I can only flex it together so much. The quick-release skewer has a thread on the other end, but that is only a plastic knob, and the skewer is only a 4-5mm rod. Not intended to be tightened with great force.

Of course, I complained about this, sent them an email. This was the reply:

i checked with engineer, he said can put some washers

Hmmm... The seating for the hub is only 5mm, even less on the other side. I don't think that I would put a washer on the other side, as perhaps it would compromise the derailleur gear mechanism. That would mean a 2mm washer on the non-gear side. Hmmm again.

Try and tighten the skewer even more? I am afraid of breaking the

plastic knob.

So, I'm wondering if can get away with bending the forks slightly together. Aluminium is generally more brittle than steel, but it depends on what additives are in the aluminium. I presume that this trike frame would have a fairly malleable aluminium formulation. So maybe can clamp the forks together, just enough to bend a few millimetres.

Anyone reading this with knowledge about properties of aluminium? A small bend doable, without weakening the forks?

EDIT 2024-06-21:

We successfully bent the fork, so problem solved. Blog post:

https://bkhome.org/news/202406/trike-320-rear-fork-large-gap-fixed.html

Tags: light