Trike test elejoy MPPT controller

In September, I posted about my collection of MPPT boost controllers:

- MPPT controller for custom trike — September 13, 2024

And further details on the Lensun controller:

- Lensun MPPT has to be isolated from frame — October 11, 2024

Decided to test the elejoy, but left the Lensun in-place, so as to be able to swap them over in just a couple of minutes:

Took the trike outside this morning, December 10, 9.50am, clear blue sky:

As mentioned, had discharged the battery a little bit, hoping to improve the behaviour of the BMS. The elejoy output is reading:

54.3V, 2.35A

Which is 127.6W

Hmmm, not as good as expected. Based upon the surface-area of the panel and inclination of sun, and past experience, I expect higher then that. Need to setup a variable resistive load for the solar panel and find its peak power point; determine what it is actually capable of. Hopefully will do that in the next couple of days.

Today, got distracted when a neighbour came over and we

chatted about the trike, lithium batteries, etc. Then I had other

stuff wanted to do today.

Tags: light

Custom recumbent trike first test

Posted yesterday about planning to put the solar panel onto the trike:

- Planning to affix solar panel to trike — December 04, 2024

Thanks to Bart and Jimmi, who emailed me with advice about adhesives. I tested the Parfix silicone on the back of the solar panel, and also on a piece of aluminium. The bond with the solar panel is incredibly strong, mediocre with the aluminium. I did not degrease nor sandpaper the surface of the aluminium, which would have contributed to the mediocre bond.

However, I decided that the bond to the aluminium is good enough, as it is likely sometime in the future will upgrade the solar panel to a higher wattage. Some adhesives are too good, making removal of the panel just about impossible. Yes, used the Parfix, as that is what already have and as stated, it is "good enough".

As mentioned in the previous post, decided to use aluminium angle to hold the panel down:

Ran a bead of silicone along underneath the panel, before affixing the angle. On reflection, probably that silicone wasn't necessary, just some applied to the internal framework to prevent flapping in a strong breeze. In fact, without silicone might have been better from the point of view of thermal expansion and contraction. Anyway, its done.

Today took it outside for a short test ride. Here it is posing in the courtyard:

Blue sky, about 10am, expected to be getting good output from the solar panel; however, the MPPT controller readings were all over the place. Here is a snapshot:

...see only 65W. Also very disconcerting, sometimes it dropped to

zero amps output for several seconds. I rode the trike around and

around in a circle, and output came up to about 153W.

The battery had been previously charged to 100%, so probably the weirdness out of the MPPT controller is due to the BMS. Hope so amyway. Now it is the evening, and have the battery on discharge, through a 220V inverter powering a 30W incandescent globe. Will let that run for a couple of hours. Tomorrow plan to take the trike outside again and see if the charging has improved. Will also try the elejoy MPPT controller.

The experience of riding the trike around in circles was pleasant. One thing, the front suspension is too soft, but I expected that, and have replacement shock absorbers with stiffer springs; will fit those soon.

A side-project has been started, a throw-over weather protection tent:

...the bottom will have hooks attached, to be pegged to the ground, and there will be more fabric glued onto the sides.

The interesting possibility with this tent is that it could be

more than just weather protection for the trike; if one side is

extended out, it could become a habitable area. Don't know; there

is no vision in the mind how this habitable area could be

achieved. Will just keep contructing it, following my nose. Note,

the fabric is very thin ripstop nylon, left over from years ago

when I was into tent construction.

Tags: light

Planning to affix solar panel to trike

Continuing the custom solar-assisted recumbent trike project, here are recent posts:

- How to look after your LFP battery — November 09, 2024

- IEC C13 versus Anderson connectors — November 06, 2024

- Junction box for custom trike part-2 — November 04, 2024

I completed the electrical wiring; motor, junction-box, speed sensor, display panel, etc., and with some trepidation flicked the "motor" cicuit breaker on the junction box to "on" and then pressed the power-on button on the Bafang control panel ...and it worked. had the rear wheel propped up on blocks of wood and was able to test the pedal assistance levels. Looking good.

The Bafang control panel mystifies me though. I mounted it right in the middle, between the legs:

...it doesn't look like it in the photo, but there is enough room for the legs either side. Could re-arrange with the buttons below the display, if want it to be narrower.

The Bafang control panel is model "DP C18.U 3.0". The "U" means that it has a UART interface, which is serial data transfer and a small round green connector.

The display reads "100%", which is what mystifies me. Where is

that determined? I have a LFP battery, which has lower cell

voltage than NMC lithium batteries that are usually used in

ebikes. I found the Bafang control panel user manual online, but

it doesn't have any settings for battery type or capacity, which

seems odd.

For the solar panel, the plan was to extrude a bead of adhesive all around, as quick as possible, then lower the panel down. Either get someone to help me, one person on each side holding the panel, or if only myself then some blocks of wood that will be removed after extruding the adhesive:

However, when I lay the panel on top of the frame, to see how it sits, found that the panel curves up at the corners:

...so, just lowering the panel down onto the adhesive is not

sufficient. It needs to be more positively held down. Note that

the framework is not twisted; I was very careful about that when

building it. It is the solar panel itself that curves up, at all

four corners.

Fortunately, I have aluminium angle that is just the right

dimensions, that was used in the aborted first attempt to build a

rigid solar panel framework. Pleased that it can be put to some

use.

Plan to do that tomorrow. The plan now is to leave the solar panel where it is, resting on the framework. Inject adhesive along one side then pop-rivet angle to hold it down. Then do same on all sides. There will also be adhesive inserted into the internal framework.

The adhesive will be general-purpose neutral-cure silicone sealant. This is the best. There are a lot of specialist adhesives; however, after much online reading I settled on ordinary silicone sealant. The primary reason is its flexibility; some other adhesives, even those recommended for securing flexible solar panels, are not flexible and can actually damage a solar panel. Or so I have read.

Regarding the MPPT charge controller, that has been wired with XT60 connectors:

...the connector without anything plugged to is for the solar panel. The solar panel +ve wire goes through a switch then into the MPPT controller. Output from the controller goes vertically down as shown on the left of the photo, to the junction-box.

EDIT:

Here is one of the sites that recommends a flexible silicone

adhesive:

https://www.solar4rvs.com.au/buying/buyer-guides/flexible-solar-panel-mounting-instruction-guide/

They recommend Sika SG20, which is sold locally at Bunnings. I already have a tube of general-purpose neutral-cure silicone sealant, and I wonder if there is much to be gained by going for the much more expensive SG20. Here is the company's SG20 web page:

This is what I currently have:

https://www.bunnings.com.au/parfix-300g-clear-all-purpose-silicone_p1232674

...seems OK?

Tags: light

How to look after your LFP battery

I have posted before about the two main classifications of lithium battery; NMC (nickel manganese cobalt) and LFP (lithium iron phosphate, also known as LiFePo4). There are a lot more classifications and in-between classifications, but these are the most well-known two.

A lot of online information is for NMC, which is why this little video is so good:

"The rules of LiFePo4: The 3 Most Common Causes of Failure and

General Guidelines for Long Term Use"

https://www.youtube.com/watch?v=UbZiHzflKMY

That is good advice about charging periodically to 100%, though I'm not so sure about 0% ...nor really what constitutes "0%"

My powerbox battery that I built for camping seems to have a very low self-discharge. I haven't measured it, just left it in the closet for many months. It was in the closet for about 6 months at about 80% and when I got it out, it still "seemed" to be 80%.

I say "seemed" because that was the reading on the coulomb meter.

Reading the voltage of an LFP battery is not an accurate way to

determine state-of-charge, as LFP batteries have very slow voltage

drop as the battery discharges, compared with NMC.

This site explains that LFP batteries have a lower self-discharge than NMC:

https://ecotreelithium.co.uk/news/lithium-nmc-vs-lifepo4/

...but the comment about LFP "no thermal runaway" -- that's a new

one on me. Also, regarding self-discharge, I have read online the

exact opposite; that LFP are slightly higher than NMC. The rule;

take everything that you read with a grain of salt, including from

"trusted" sources (see my previous blog post, here!)

Tags: light

IEC C13 versus Anderson connectors

Continuing with the custom trike project, here are the previous three posts:

- Junction box for custom trike part-2 — November 04, 2024

- Junction-box for custom trike — October 17, 2024

- Lensun MPPT has to be isolated from frame — October 11, 2024

Something that has surprised me, is the use of the IEC C13 connector for DC. This connector is intended for mains AC, yet, this is what my lithium battery came with for charging:

To be fair to the vendor, they did offer a choice of other connectors, but I just accepted the default. Looking on Aliexpress at lithium batteries and chargers, it seems this IEC C13 is the usual default choice.

Awhile back, I bought another mains charger, 58.4V, for my LFP battery; they also offered a choice of connectors, but I chose the IEC:

https://www.aliexpress.com/item/1005003269750911.html

But, that really does look "wrong":

...the connector on the left is the 58.4V DC output, on the right is the 240V AC input!

This does not rest comfortably with me. So, decided to replace

the DC connectors with 50A Anderson. The choice of Anderson is

partly because I have some already, and partly because they have

holes for convenient mounting. Of course they are an overkill for

the 3-4 amps in this situation.

In the earlier "powerbox" project, I standardized on different colour Anderson connectors; black for the mains charging. So sticking with that. Used the "flood" method of soldering the wires to the Anderson lugs, as explained in my blog a few years ago, here.

The problem that arises from replacing the IEC connector with Anderson, is that with the Anderson connector the wires will flex a lot more and will in time likely break, especially if they have been stiffened by solder having flowed up the wires. So I fabricated a simple brace with a small piece of steel offcut:

|

|

|

...one thing I learnt from the powerbox days, is that the internal lugs need to have some freedom of movement. Back then, was using much heavier guage wire, and if the two wires were pulled together it also twisted the internal lugs and made plugging together of two connectors very difficult. It is not such an issue with these thin wires; however, I splayed them out a bit and wound the electrical tape a bit further back.

Next up, will replace the IEC connector on the lithium battery with an Anderson -- will do that with great care! Branching off from that will be a XT60 connector to which will be plugged charging from the solar MPPT controller -- as discussed in the previous blog post with regard to the DPDT switch.

One interesting detail about the bolt inserted though the

Anderson connector; it is 4.0mm, whereas the hole is 3.7mm. I was

surprised at such an odd size hole, but perhaps it has heritage

from imperial measurements. That got me curious; yes Anderson

Power Products is a USA company. Not that most people buy an

actual Anderson brand connector, but they are the originator.

Anyway, I drilled it out to 4.0mm.

Tags: light

Junction box for custom trike part-2

Part-1 was posted a few weeks ago:

- Junction-box for custom trike — October 17, 2024

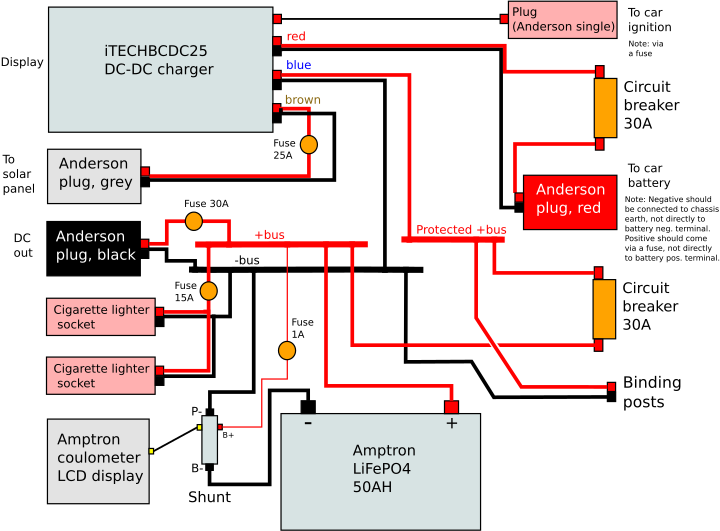

At the time, made an assumption, and thought could get away with it. Previous experience with a lithium battery was when I built a "powerbox" for camping; see here. Reproducing the diagram from that post:

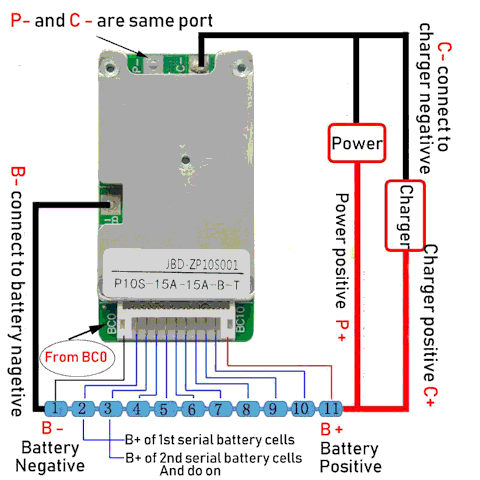

...the battery has one +ve and one -ve terminal. However, the LFP battery that I purchased from China to use on the trike, has two separate pairs of wires, for charging and discharging. Connecting the charging and discharging wires together, might not work!

I'm a retired electronic engineer, but lithium batteries are recent tech. Hey, I even learnt about vacuum tubes when I did my degree! Anyway, I've been reading up on BMSs -- Battery Management Systems for lithium batteries -- so much more complicated than lead-acid batteries!

This webpage explains that with some BMS you can connect charge and discharge wires together, some you can't:

https://www.elecycles.com/blog/post/what-is-electric-bike-lithium-battery-bms/

Beware, that "P-" and "C-" might measure as zero ohms; however,

there may be shunts for the BMS to measure incoming and outgoing

current. Shunts are very low resistance, that might not show up in

the multimeter and you might think P- and C- are wired together --

and if you do connect them together externally, it will stuff up

the BMS. So you do need the specs for the BMS to be sure that the

two negative wires can be (or are) connected together.

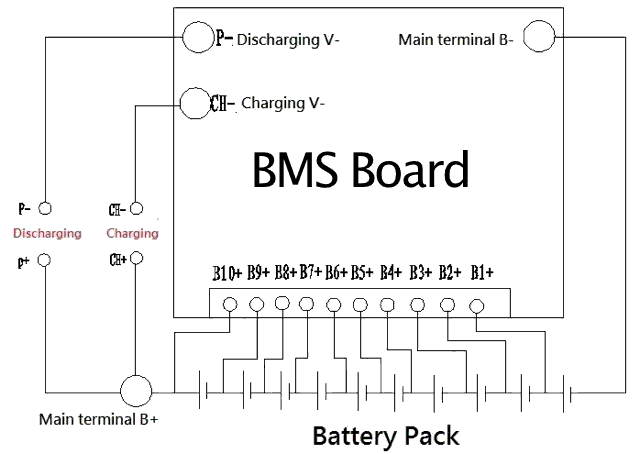

Here is another BMS diagram:

I don't know what kind of BMS is inside my battery, nor do I want to cut open the shrink-wrapping to find out. Besides, it may be that the BMS is a Chinese part for which I cannot find manufacturer specs. So, I have decided to "play safe"...

Here is the simplified diagram from the junction box part-1:

...the +ve wire from the solar panel MPPT controller is going through a circuit-breaker to the battery; the discharge terminal of the battery. The -ve wire from the MPPT controller to common-ground, which goes to the -ve discharge terminal of the battery.

I did some reading on whether can charge through the battery discharge terminals, and maybe ok, except might cause issues with cell balancing. It might be good that the MPPT controller is going straight to the motor (via another circuit breaker), bypassing the battery.

Decided that need to experiment. Have put in a DPDT (Double Pole Double Throw) switch, so can switch the +ve and -ve wires from the MPPT controller, either as shown in above diagram, or to the charging terminals on the battery.

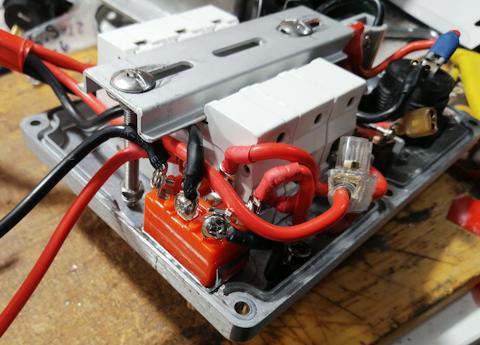

It was a tight squeeze:

The front panel:

...next time go the workshop, will use an etching pen to write

what the new toggle switch does.

Making no assumptions about how the BMS works; when the toggle switch is flipped to send the MPPT +ve and -ve direct to the charging input of the battery, completely separate from the battery output +ve and -ve. I'm not even assuming a common +ve as is shown in the above BMS diagrams.

This toggle switch is going to be something to play with when riding the trike. I read somewhere that some BMSs don't like being charged and discharged at the same time, in which case setting the toggle switch to MPPT direct to battery output would be good. Does the BMS have "pass through" so that charging while discharging will just pass the charging current direct to the output? -- have no idea whether my BMS will do this.

Fun times ahead. The trike project is advancing so slowly. Most

of my time has been on EasyOS, apart from having a life. Anyway,

will see if can progress the trike project, as really want to ride

it while still summer here. I'm in the Southern hemisphere, so

summer just starting.

Tags: light

Junction-box for custom trike

Continuing the custom tadpole recumbent trike project, here are recent posts:

- Lensun MPPT has to be isolated from frame — October 11, 2024

- Custom trike luggage rack completed — October 04, 2024

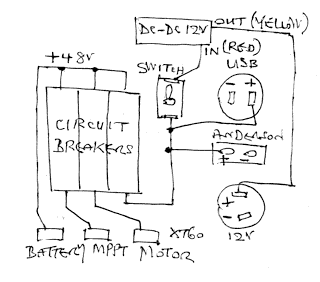

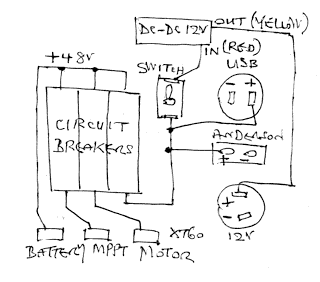

I have now constructed a "junction box", with circuit breakers and various input and output plugs and sockets. Here is a simplified sketch:

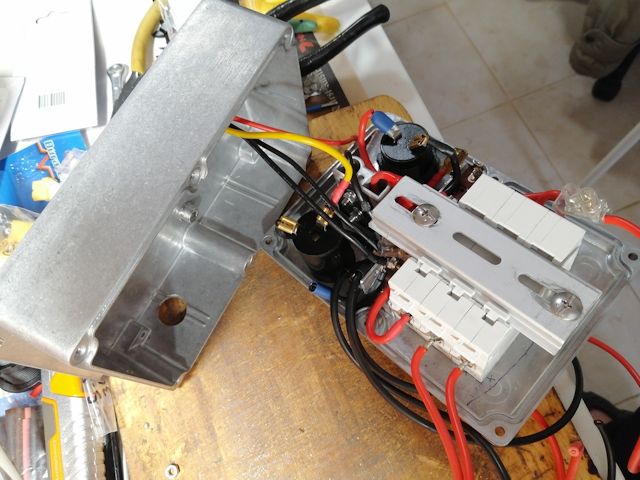

...the negative wires are not shown; they are all connected together, in a star configuration. Photo of inside of the box, mostly assembled:

Another view:

It is a snug fit. Could have used a bigger aluminium box; however, wanted one with side-flanges, for convenient mounting, and Jaycar, a local store near me, had limited range. I bought this one.

The box is going to be mounted underneath the seat, where I can reach down and flip the "motor" circuit-breaker to get going. There is also a "mppt" circuit-breaker that goes to the solar-panel MPPT controller, and an "output" circuit-breaker that connects the battery to output sockets -- Anderson socket to bring out the 48V battery, USB sockets and 12V accessory (cigarette lighter) socket.

The USB and Anderson socket combo also came from Jaycar, here. However, what I did not realise, is that the USB panel-mount socket is also available with higher input voltage. The ones from Jaycar and everywhere else locally, are 12 or 24V input. But I discovered in Aliexpress, they are also available for electric-vehicles, input voltage up to 90V. So, I bought this one:

https://www.aliexpress.com/item/1005001756428902.html

The back of the aluminium box has a DC-DC converter mounted, input from the "48V" battery, output 12V going to the accessory socket. Photo of back:

If I had stayed with the Jaycar USB socket, with only 12V input, would have had to go through two DC-DC converters, which is very inefficient. Each DC-DC (buck) converter is about 90% efficient. The lost power is dissipated as heat. Now, the USB socket is connected directly from the 48V battery (through the circuit-breaker). There is also a on-off switch on the USB socket.

Bought the DC-DC 12V-output converter from here:

https://www.aliexpress.com/item/1005005631226496.html

Photo of the front panel:

After taking that photo, I went to the "men's shed" workshop near me, and used an etching tool to write what each circuit-breaker is for.

A note about those external cables; they will have XT60 plugs, bought from here. Photo:

...these are popular with remote-control (RC) enthusiasts, as

well as other situations requiring small size, light weight and

high current rating. I originally bought a pack of T-plug type,

from here.

...however, found those T-plugs to be extremely difficult to plug together. Also difficult to unplug. Also, read online that the type of plastic used can soften when soldering, compromising the performance of the plug. There are some online comments that most RC enthusiasts have moved to XT60 type. Unless, I suppose if you need extreme small size.

Regarding the circuit-breakers; they are rated for DC usage. Got

them from here.

Got the "10A" ones, which might not be high enough for the motor.

It is only a 250W motor and pedal-assist, so I reasoned the

startup surge current will be modest, well below 10A. We

shall see.

Tags: light

Lensun MPPT has to be isolated from frame

Maybe. I posted last month about deciding which MPPT controller to install on my trike:

- MPPT controller for custom trike — September 13, 2024

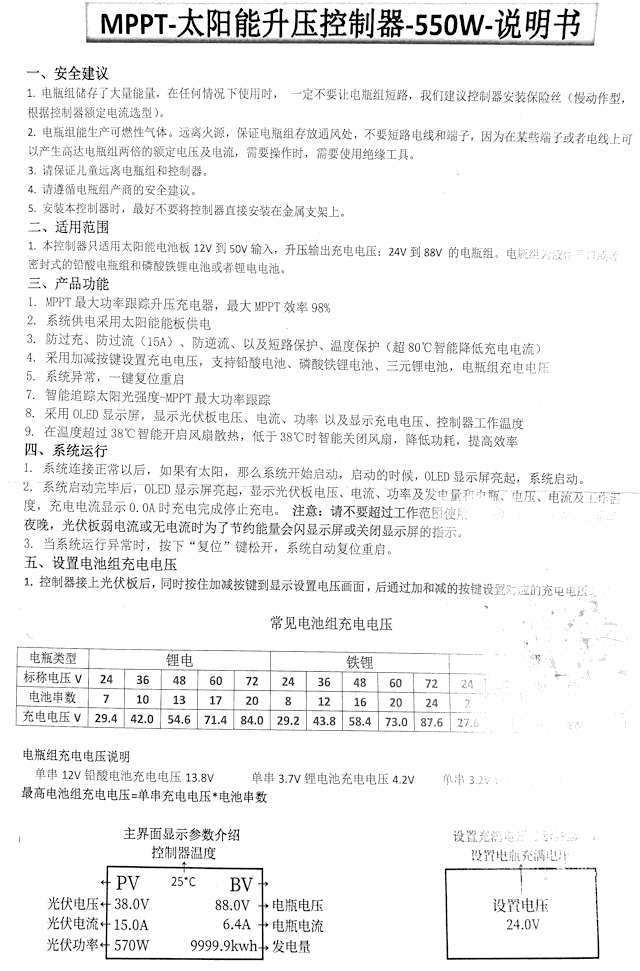

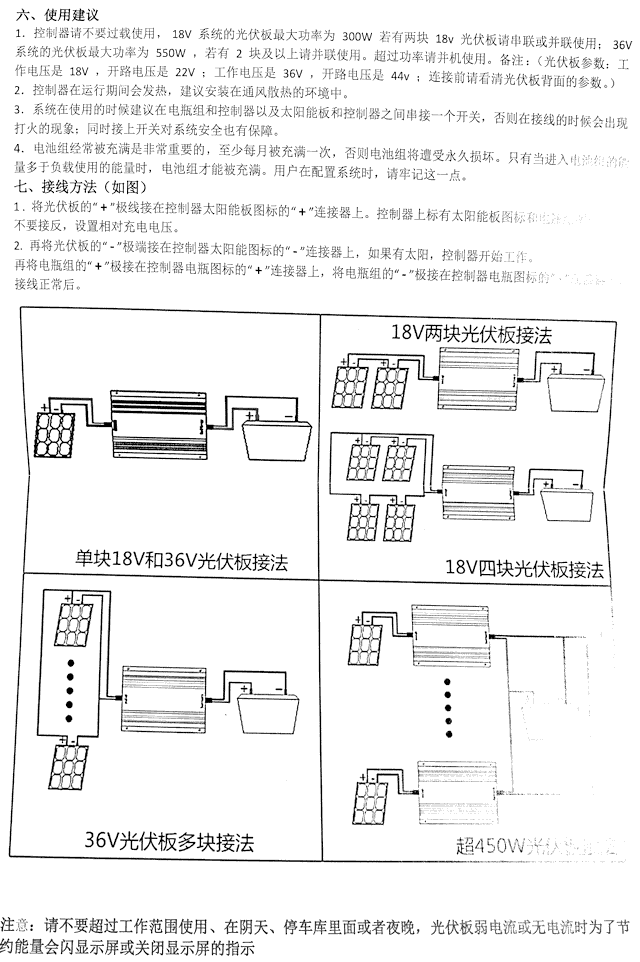

...chose the Lensun. I very much doubt the Lensun company claim that it is both a buck and boost controller, as it says nothing in the documentation supplied with the controller, other than it is a boost controller. The Lensun website shows a photo with the front panel in English; however, the one that they sent me has Chinese characters on the front panel and Chinese User Manual. Here is the manual:

Page two:

I figured out basic usage. In the above table, you can see the value "58.4" -- that is for a nominal 48V LFP battery with 16 cells. That is what the charging voltage has to be set to. I already knew that, and figured out that the "+" and "-" buttons have to be held down together to put it into output-voltage-setting mode, then the "+" and "-" buttons can be used to set the voltage.

As can be seen in the earlier blog post, installed it on the trike, bolted underneath the solar-panel frame.

All seemed good, until a few days ago I was able to translate the manual to English. EasyOS has gImageReader, installable via PKGget (only recently added to the repository, see blog post). This is an OCR (Optical Character Recognition) app, which produces output as Chinese text. I then fed that to translate.google.com and got English.

It is all OK, except for this paragraph:

5. When installing this controller, it is best not to install the controller directly on the metal bracket.

...very interesting statement! My guess is that the power switching transistors are bolted to the controller heatsink frame with electrical-insulation. In ye olden days, this might have been a thin sheet of mica. It might be that they are not guaranteeing this isolation, hence covering themselves with the above statement.

Or, maybe they have only made that statement to reduce vibration.

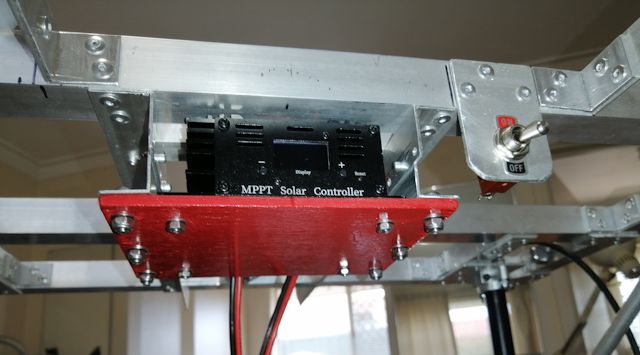

Anyway, I decided to remount the controller isolated, on a small piece of plywood. Used plywood intended for internal use, so painted it for some external protection. Only two spray cans to choose from; black or red enamel. Choose red. Intended for metal, but reckon OK on the plywood. Put on three coats. Here it is mounted:

...quite easy to remove, convenient for testing the other controllers.

Ah yes, removal. First time bolted on, I used Loctite (medium strength) and locknuts. Only m4 bolts, but just about impossible to undo. Have used this combination all over the place on the trike, but as I discovered, the combination of Loctite and locknut is just too much. Got them undone, but was amazed that the bolts didn't sheer.

Those bolts are good quality. I bought plastic flip-top boxes of assorted lengths of bolts/nuts/washers and allen-key from Aliexpress, very handy. Bought m4, m5, m6, m8 boxes. They are 304 stainless steel -- that is not "marine grade".

The complete English translation is here: page 1,

page 2

In the previous blog post, I mentioned a MPPT controller on

Aliexpress that looks like the Lensun, but a fraction of the

price. Yeah, I couldn't resist. Bought it ....and it looks

identical to the Lensun. Don't know about internally. Do plan to

test my collection of MPPT controllers on the trike sometime in

the future.

Tags: light